Manufacturing has long been defined by large-scale production runs, extensive inventories, and long lead times. But as market demands shift, businesses are looking for more efficient and responsive ways to produce goods. On-demand manufacturing is emerging as a powerful alternative, enabling companies to create products only when needed. This approach minimizes waste, optimizes costs, and allows businesses to react quickly to customer needs.

Unlike traditional manufacturing, which relies on forecasting and bulk production, on-demand manufacturing leverages advanced digital technologies to make parts and products only when an order is placed. This transformation is particularly beneficial for industries that require high customization, rapid prototyping, or low-volume production. As companies continue to seek agility and efficiency, on-demand manufacturing is becoming an essential strategy for modern production.

What is On-Demand Manufacturing?

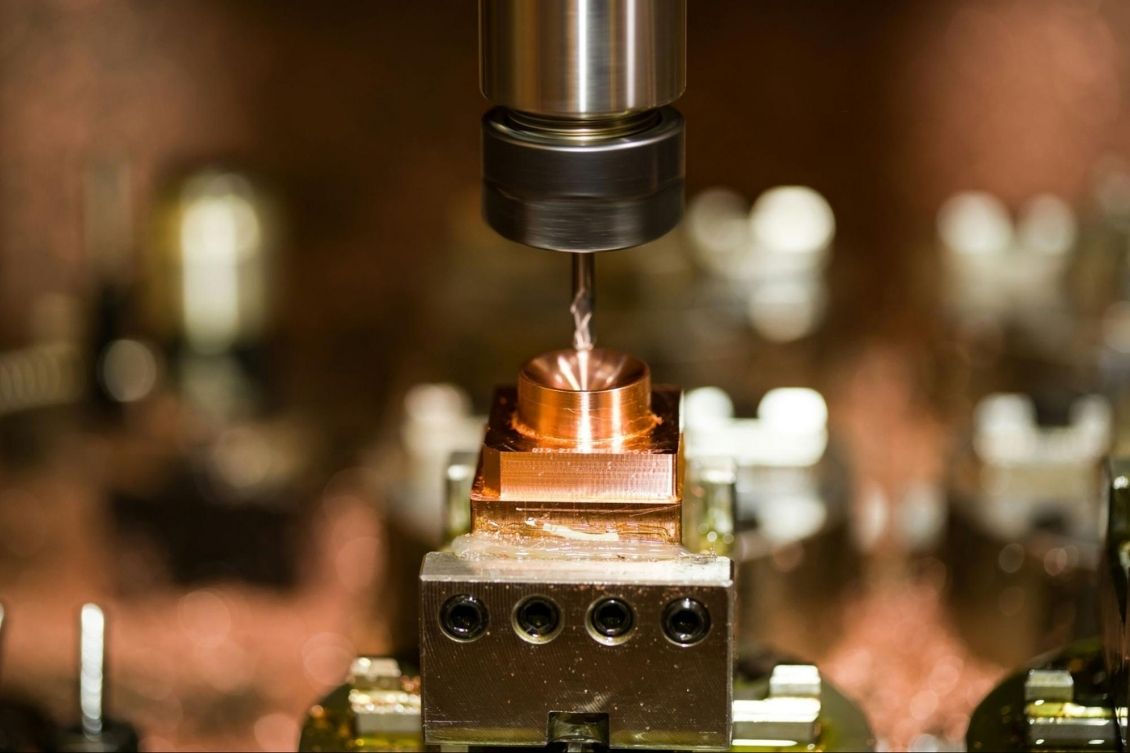

On-demand manufacturing is a production strategy where items are made only when orders are placed, rather than being mass-produced and stored in inventory. This approach leverages digital manufacturing technologies like 3D printing, CNC machining, and automated fabrication to quickly produce high-quality parts and products.

Key Benefits of On-Demand Manufacturing

Embracing on-demand manufacturing provides businesses with several competitive advantages. By shifting from traditional bulk production to a more responsive and efficient model, companies can reduce costs, improve speed to market, and enhance overall sustainability. Here are some of the key benefits of adopting on-demand manufacturing:

Lower Inventory Costs

Traditional manufacturing requires large-scale production and storage of parts, which ties up capital in inventory. On-demand manufacturing eliminates the need for excess stock, reducing storage costs and minimizing waste.

Faster Turnaround Times

By leveraging digital workflows and automation, manufacturers can quickly respond to customer orders, producing and delivering products faster than conventional methods.

Greater Flexibility

Companies can adjust production based on demand, making it easier to handle custom orders, small batch production, and design iterations without incurring high costs.

Sustainability

Reducing excess inventory and only manufacturing what is required significantly lowers material waste and energy consumption, making it a more sustainable approach.

Cost-Effective Prototyping

On-demand manufacturing allows businesses to create prototypes and test designs before committing to large-scale production, reducing risks and ensuring product quality.

Conclusion

On-demand manufacturing is reshaping how products are designed, produced, and delivered. As digital manufacturing technologies continue to advance, companies that embrace this model will gain a competitive edge by being more agile, cost-efficient, and sustainable.

Are you ready to optimize your production process? Explore how OpenBOM can help streamline your on-demand manufacturing strategy today with our Free 14-Day Trial!

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.