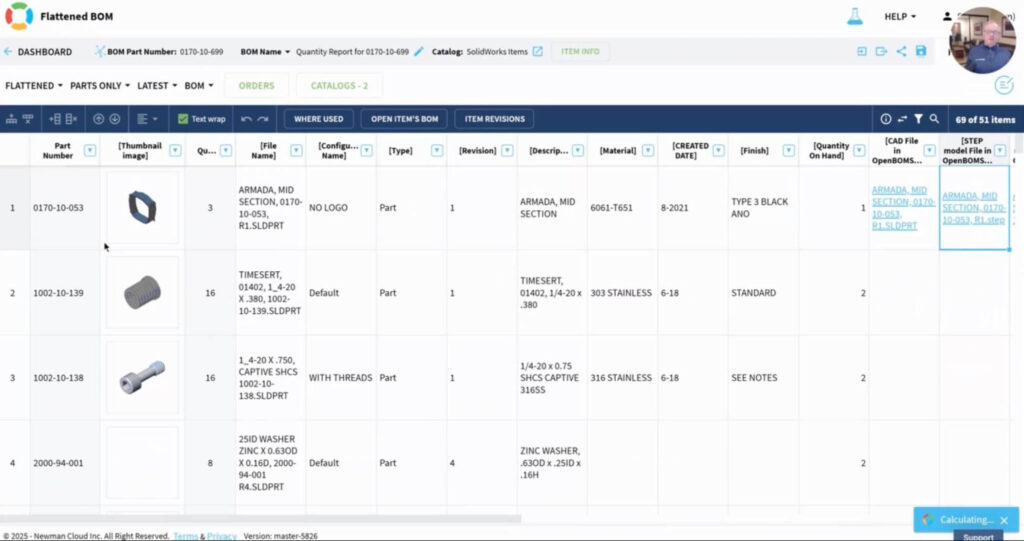

Managing product structures efficiently is crucial for engineers and manufacturers. OpenBOM provides powerful tools to visualize and organize Bills of Materials (BOMs), including the Flattened BOM, which automatically rolls up quantities across multiple levels of assemblies and sub-assemblies. By default, this view includes both parts and assemblies. However, what if you need to see only the parts (leaves) in the product tree?

In this blog, we’ll walk you through the process of creating a special view in OpenBOM that filters out assemblies, preserving the correct quantity roll-up while displaying only the essential components.

What is a Flattened BOM?

A Flattened BOM is a structured report that consolidates quantities of items across different assembly levels into a single, summarized view. This is especially useful for procurement, inventory management, and cost estimation, as it provides a clear and concise list of all required parts.

By default, the Flattened BOM in OpenBOM includes both parts and assemblies, which might not always be ideal if you are looking for a pure parts list.

Why Create a Special View for Only Parts?

When analyzing or exporting BOMs, it’s often useful to filter out assemblies and see only purchased or manufactured components. This makes it easier to: ✅ Generate accurate procurement reports ✅ Export clean data to ERP systems ✅ Avoid confusion with assemblies in part ordering ✅ Streamline communication with suppliers

OpenBOM allows you to create custom views using filters, enabling you to tailor the BOM display to your exact needs.

Step-by-Step: Creating a Special View to Show Only Parts

Follow these steps to set up a custom view in OpenBOM that displays only parts in a Flattened BOM.

1️⃣ Open Your Flattened BOM

- Navigate to your BOM in OpenBOM.

- Click on the Flattened BOM option to generate a consolidated view of all items across all levels.

2️⃣ Create a New View

- Click on the View dropdown at the top.

- Select “Manage Views” to customize how BOM data is displayed.

- Click “Create New View” and give it a descriptive name, such as “Only Parts”.

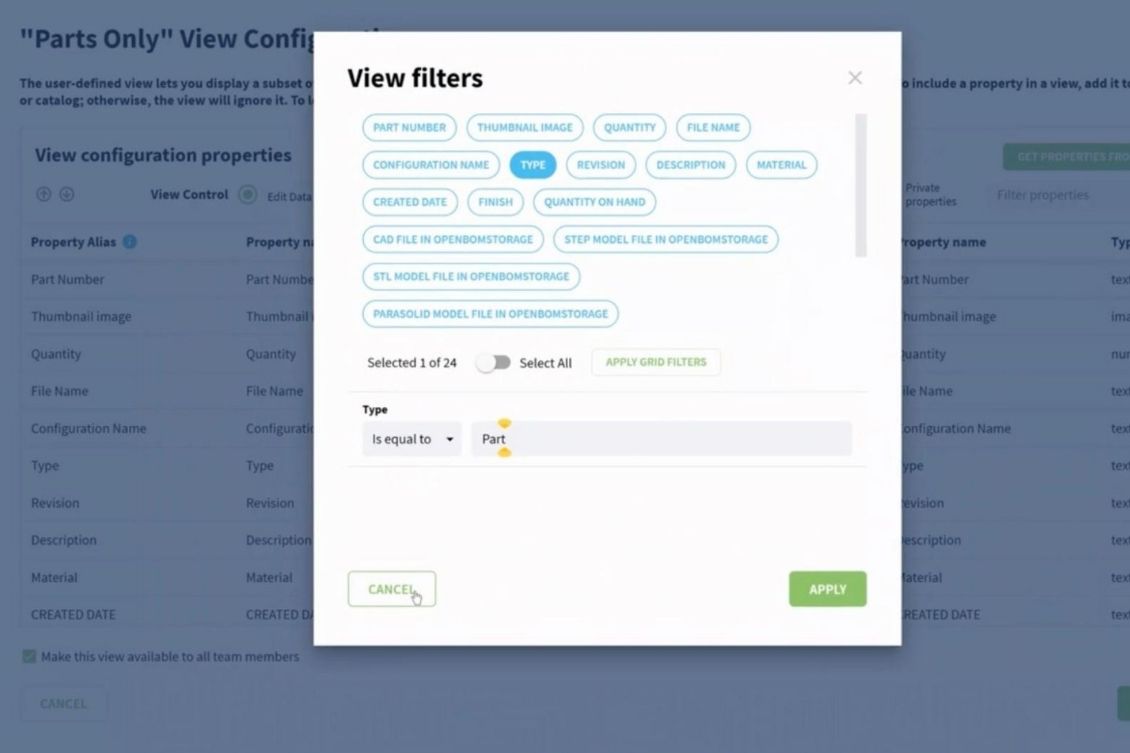

3️⃣ Apply a Filter to Exclude Assemblies

- Locate the Item Type column in your BOM.

- Set a filter condition: Item Type = “Part”.

- This will automatically remove any row where the item type is an assembly, leaving only individual parts in the view.

4️⃣ Save and Apply the View

- Click Save to finalize your special view.

- Apply this new view whenever you need a quick parts-only report!

5️⃣ Export to Excel or Other Formats (Optional)

- Once your filtered view is ready, you can easily export it:

- Click Export and choose Excel, PDF, or CSV format.

- Share the file with procurement teams, suppliers, or integrate it with ERP systems.

A Video of How To Setup Parts-Only Flattened BOM

With this setup, you’ll have a parts-only Flattened BOM, ensuring clarity and precision in your product data. This streamlined approach helps with accurate procurement, manufacturing planning, and data integration.

Conclusion

Here are key benefits of using a parts-only Flattened BOM. 🔹 Eliminates unnecessary assemblies from the view 🔹 Preserves accurate rolled-up quantities 🔹 Simplifies ordering and procurement workflows 🔹 Enables seamless data export and reporting 🔹 Reduces errors in supply chain communication

This quick customization can make a big difference in how you manage your BOMs. Log in to OpenBOM today and set up your custom “Only Parts” view to improve efficiency and streamline your workflow.

📢 Need more tips? Subscribe to our blog and YouTube channel for the latest OpenBOM insights!

🔗REGISTER FOR FREE and give OpenBOM a try.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.