Manufacturing custom parts is no easy task – but it doesn’t have to be an arduous one either. With the right process and tools in place, you can quickly and easily order the custom parts you need. By understanding how the ordering process typically works, understanding your options for customization, and getting organized in advance of bidding on a project, you can streamline your approach to obtaining custom parts.

In this blog post, I’m super excited to share the news about OpenBOM and ManuFuture partnership and integration and introduce you to both capabilities of the ManuFuture platform and integration between both platforms. Let’s take a closer look!

What is the ManuFuture Platform?

ManuFuture is a B2B marketplace for custom parts manufacturing. The platform enables users to order-track-receive their parts from a globally vetted network of suppliers, the all-in-one solution makes custom parts production simpler and more cost-efficient than ever.

ManuFuture online platform provides full support for the duration of the custom parts manufacturing including production requirements management, engineering data, production files, and direct communication collaboration. The main function of ManuFuture is to organize and support the process of ordering custom parts. Here is the list of ManuFuture functions available as part of the platform:

- Easy way to define engineering and commercial requirements

- You select from which countries to get quotes from

- Choose bid and delivery times

- Anonymous and encrypted bids

- Collaborate and communicate directly with suppliers for questions and answers

- Select the preferred quote for each project including unit, shipping, and handling prices

- Track the production and delivery status

- Manage different destinations for parts to be delivered

- Get a 100% guarantee on the quality of the parts

The process is simple, and efficient and ensures that users always receive the best possible delivery times with the best prices for their custom parts.

Why ManuFuture and OpenBOM?

Digital transformation is one of the most visible trends in manufacturing. Companies are looking at how to transform their operation and use digital technologies to optimize the process and the outcome of the manufacturing – optimize cost, eliminate supply chain risks and streamline the operation.

Manufacturing companies are looking for modern cloud-native and connected tools that can help them to operate efficiently and manage processes effortlessly. ManuFuture and OpenBOM give their customers these capabilities.

The integration of ManuFuture and OpenBOM provides manufacturing business and hardware companies with enhanced capabilities in product management and supply chain efficiency.

It includes BOM management functions, advanced supplier information, RFQs, purchase order support and can provide a complete view of the project delivery lifecycle. ManuFuture integration with OpenBOM supports the decision process that can positively affect production and operations, resulting in better utilization of resources and lower costs.

ManuFuture and OpenBOM Integration Functions

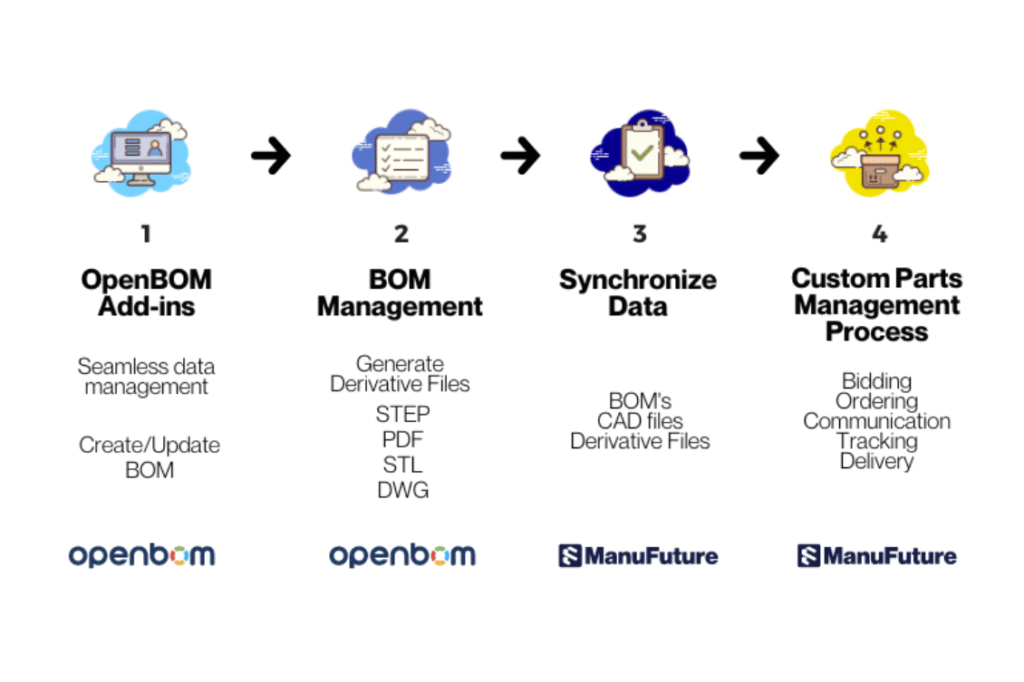

The integration brings the best functions from both ManuFuture and OpenBOM platforms to perform seamless integration and data handover to streamline the process. The goal is to exclude an inefficient paper and document-based process with a modern connected cloud-native experience.

Digital BOM Management and CAD Integrations

OpenBOM is a cloud-native PLM platform to support a digital bill of Materials (BOM) management capabilities to create a single source of truth for your product and project information and to manage BOMs in a centralized repository.

OpenBOM seamless integration with all CAD tools allows automatic and effortless information capture from the engineering environment, which includes all needed data (Items and BOMs) and files (native CAD files, derivative formats such as PDF for drawings, STEP, STL, and others for CAD files)

OpenBOM multi-tenant architecture allows easy connection and data sharing with all project participants – engineers, production planners, procurement managers, and others. With OpenBOM, users can easily share BOMs with collaborators, track changes, and manage revisions.

ManuFuture OpenBOM Integrated Functions and Benefits

The integration allows users to automatically generate BOMs using OpenBOM and synchronize full product information with ManuFuture. As a result, users have a single source of truth for the entire project information, to support the sourcing process for custom parts and to eliminate the manual sourcing and procurement process.

Here are the benefits manufacturing companies can get from the integrated custom part sourcing process using OpenBOM and ManuFuture.

- Improved accuracy of Bill of Materials. There is no manual data re-entry and files handover. By synchronization of BOM and CAD data, users can be confident that they are always working with the most up-to-date information for custom part bidding and ordering

- Eliminate manual BOM creation and preparation data for ordering. OpenBOM seamless integration with CAD tools, efficient BOM management, and collaboration streamline the process and saves time for engineers allowing them to focus on design tasks.

- Improved collaboration between participants in engineering and manufacturing processes. All team members can get access to shared BOMs easily and track changes. It improves collaboration and simplifies the work when team members are located in different places.

- Streamline change management processes and design to the manufacturing process. You can get updated BOMs and file revisions for production seamlessly and reduce the number of mistakes.

- Optimize the procurement process to lower costs and get the best prices directly updated in the digital BOM management environment.

Conclusion:

OpenBOM and ManuFuture partnerships extend both platforms’ complementary functions by providing an integrated and connected platform to support project data management, collaboration, and custom part bidding processes. OpenBOM and ManuFuture partnership gives you a simple way to manage the entire product development process. This includes product lifecycle management, project management, quality management, document collaboration, and custom parts bidding process. Both OpenBOM and ManuFuture are cloud-native platforms that give you access to all these features globally anywhere in the world.

Stay tuned for more information. We are planning to include the first group of manufacturing companies to try OpenBOM ManuFuture integration. If you’re interested in testing it, please let us know – we would be happy to discuss it.

In the meantime, REGISTER FOR FREE to check how OpenBOM can help you or get quotes with no charge from ManuFuture by simply signing up and uploading your files.

Please contact OpenBOM support and ManuFuture to request a demo of integrated OpenBOM and ManuFuture solutions.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.