Terminology is everything. Ask two engineers a question and, if you’re lucky, you will get three answers. But don’t be surprised if you will get more. All names I mentioned in the title of this blog means basically the same thing, but engineers call it differently.

Product Structure

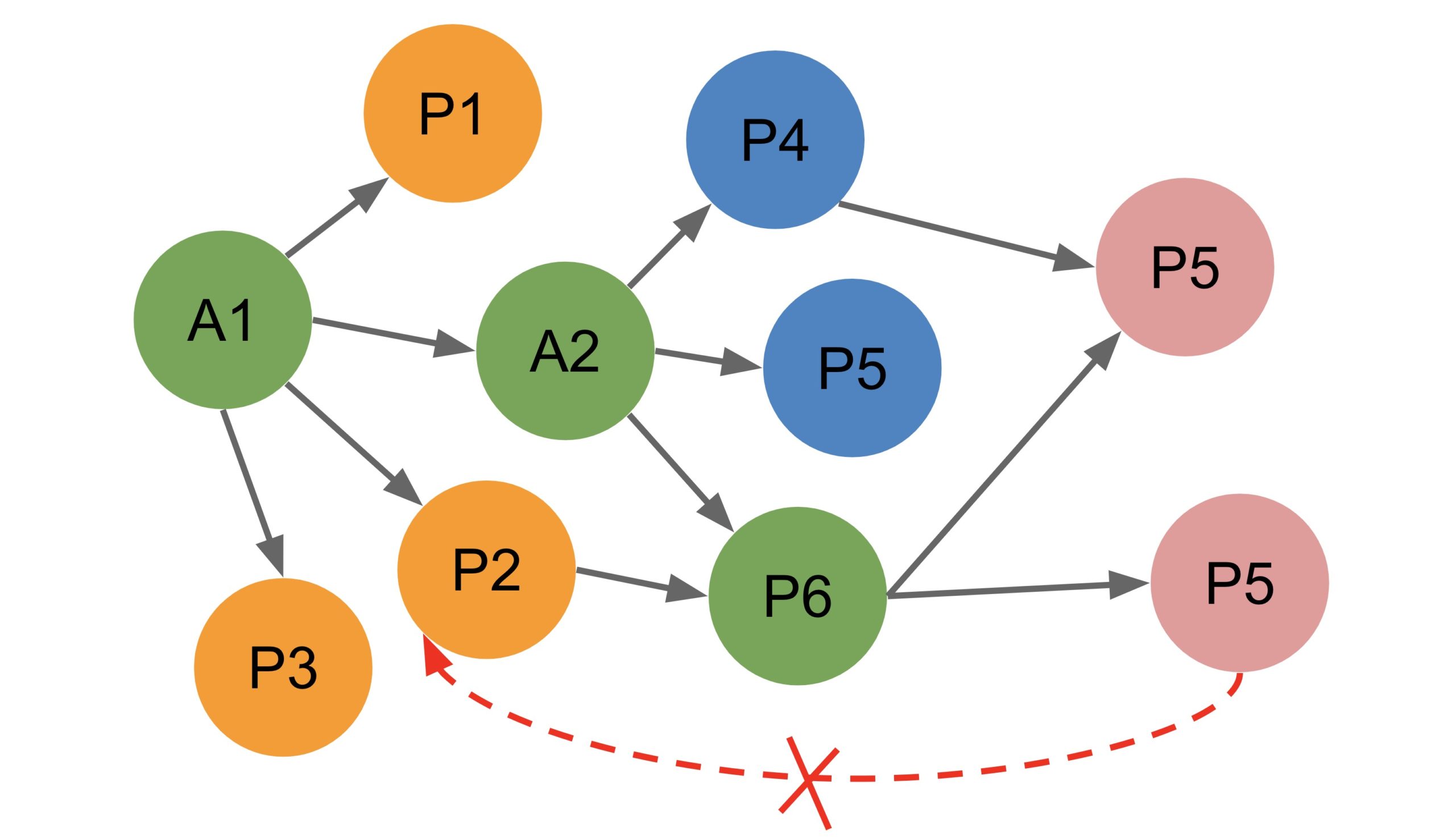

In my experience, product structure is the best definition of explaining the breakdown of components and their relationships. The foundation of product structure is a set of relationships between levels. Usually called Parent-Child relationships, they typically defining the structure of assemblies, sub-assemblies, and components (parts). The abstraction level can be used by any type of hierarchical structure usually called DAG (direct acyclic graph – graph with no cyclic relationships).

Indented BOM

Coming from the bad Excel practice of managing structure as a list of indented part numbers, it produces a poor man structure of levels. Engineers are typically using it to describe the structure of assemblies and components.

Multi-Level BOM

In many old systems such as MRPII, the BOM usually was presenting only one level. The so-called single-level BOM was displaying for each assembly, a list of components. While every item in the list can be a Part Number of another assembly, you were able to drill down, level by level. Hence the name coming out of this process – multi-level.

Parent-child relationships

Another name, which is mostly used to describe data structures, but applies to product structures and bill of materials. Each pair of Assembly-SubAssembly is forming a type of relationship in which a higher level is called a Parent and a lower level called a Child. Hence Parent-Child relationship in BOMs.

How OpenBOM manages product structure and relationships?

OpenBOM core data model is capable to manage the parent-child relationships. OpenBOM has a sophisticated data model allowing users to build parent-child relationships on the fly in both the Top-Down and Bottom-Up approach. OpenBOM is using Part Numbers to create a relationship between. The first Part Number is coming from a BOM Part Number and the second is coming from the line item.

How does it work in practice? Whenever you create a BOM (using catalog or just a command create a BOM). you give a part number to the root of the BOM. Hence BOM part number basically means an Assembly Part Number. Each line item added to the BOM forms parent-child relationships on the fly. If the Part Number suddenly belongs to another BOM, then you will get a chain of BOMs.

See the following video for example how it works.

Conclusion

Product structure, multi-level BOM, indented BOM, Multi-level BOM. All these things mean the same and reflecting the product structure of assembly relationships managed by OpenBOM. The uniqueness of OpenBOM is full flexibility combined with the cloud storage and system architecture.

Check what OpenBOM can do for you – REGISTER FREE

Best, Oleg @ openbom dot com.

Want to learn more about PLM? Check out my Beyond PLM blog and PLM Book website. If you’re in the manufacturing business, you have heard about PLM! Check out the product life cycle definition and how it traces changes of the product from the early stages of ideation to later stages of maintenance and support.

Read OpenBOM customer reviews on G2 Crowd to learn what customers are saying about OpenBOM.

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.