We’ve all heard the saying: “It’s all about the data.” But here’s the real question in 2025: Which data? And more importantly — what do you do with it?

In the world of PLM, there’s been a quiet but critical shift. For years, we focused on controlling data — storing it, managing access, and building APIs. While PLM is moving beyond just managing documents, I’d call it Data as a Service (DaaS). The idea was simple: deliver the data someone asks for, when they ask for it. PLM companies are moving into this directions

But here’s the thing: DaaS is no longer enough.

Because data access doesn’t guarantee impact. And a growing number of product teams are realizing they don’t just need data — they need outcomes.

That’s where Data as a Product (DaaP) comes in.

Data as a Service vs. Data as a Product

Let’s talk about the difference.

Data as a Service says: “Here’s your data.” It’s an API, a spreadsheet, and a database query. It’s plumbing.

Useful? Sure. But also raw, messy, and often out of context.

Data as a Product says: “Here’s data you can actually use.” It’s curated, reliable, and designed with the user in mind — whether that’s a procurement manager, a shop floor technician, or an AI model making decisions. It’s not just about serving data. It’s about delivering value.

And in this new model, the data isn’t an afterthought. It’s the product.

So, What Does That Look Like in PLM?

Let me give you a real example — one we see all the time at OpenBOM.

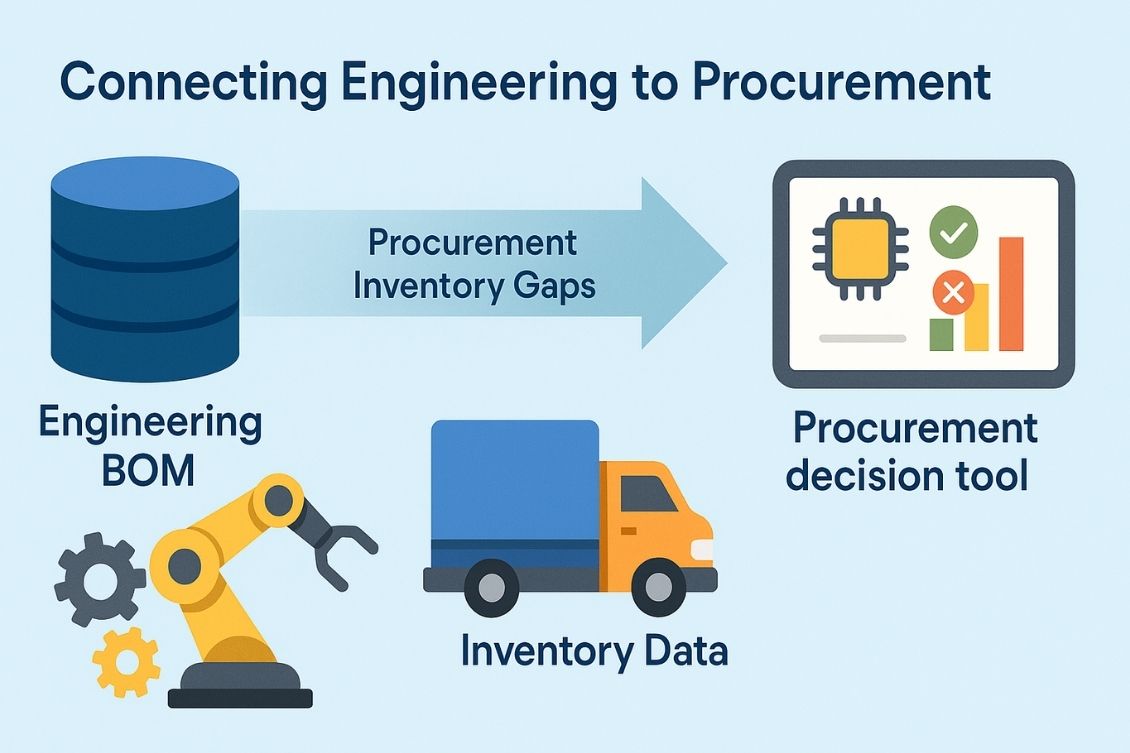

In the old world of PLM, engineering creates a Bill of Materials (BOM) and sends it off to procurement. Maybe it’s exported from CAD, maybe it lives in a PLM system, maybe someone sends a spreadsheet by email. Either way, the BOM gets “handed over” and someone in purchasing now has to figure out what to do with it.

It’s a bit like saying:

“Here’s the recipe — now go shop for ingredients, even if we don’t tell you what’s already in the pantry.”

Procurement gets the list of parts, but now they have to check what’s in stock, figure out what’s missing, search supplier catalogs, run calculations, and manually build a purchase plan.

That’s not a product. That’s homework.

Building Outcomes, Not Just Records

At OpenBOM, we take a very different approach.

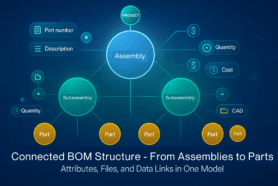

Instead of just generating a BOM and saying “good luck,” we treat that BOM as part of a data product — something intentionally crafted to serve a purpose. We connect it in real time to your company’s inventory. We bring in supplier data. We calculate procurement gaps — instantly. And we present that information in a way that’s clear, actionable, and timely.

So now, when procurement opens OpenBOM, they’re not staring at a list of parts and wondering what’s missing. They see exactly what’s needed, how many are in stock, where the gaps are, and which vendors can fulfill them — all in one view.

That’s not just access to data. That’s a decision waiting to happen.

From Model Editors to Decision Engines

And that’s the big shift happening in PLM — or at least, the shift that needs to happen.

Most PLM systems still behave like editors of data models. They’re great at storing files, managing revisions, and maintaining control. But ask them to deliver a business outcome — to help someone take action — and they fall short.

Because they were never designed for that.

They were designed to govern data, not to make it useful.

At OpenBOM, we believe that the future of PLM isn’t about bigger data models or tighter control. It’s about delivering the right data, at the right time, in the right context — so people can do their jobs better. In other words, it’s about turning data into a product.

Conclusion:

Traditional PLM is focusing on the creation of data and building APIs to expose records and provide access to them via API or so-called PLM Editors. This is fine – you can build APIs. You can expose records. You can check the box that says “data is available.” This is what most traditional PLM systems do.

But that’s not enough anymore.

Your users — whether they’re engineers, buyers, or operators — don’t just want data. They want results. They want tools that help them make decisions, avoid mistakes, and move faster.

That’s why the future of PLM isn’t just about delivering data.

It’s about designing it — like a product — for the people who actually use it.

That’s what we’re building at OpenBOM. A BOM is not an end goal. No one creates a BOM for the sake of having a BOM. It is an important goal, but it is not why most companies create it. They need a BOM for using it in procurement. So, the outcome allows OpenBOM to redefine the way how data is used. And this is what Data as a Product means.

REGISTER FOR FREE and check how OpenBOM can help.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.