As a manufacturing company, you rely on accurate and timely design files to produce your products. However, managing these files and the accompanying item lifecycle can be challenging. Understanding the lifecycle is important for a proper organization of information and management of change processes. The two most important elements of this data management process are the design file (eg. CAD file) and item including BOM (or product structure) information. Understanding how design files lifecycle management works, how you manage items and bills of materials can help you to organize a connected product lifecycle management.

In my article today, I want to start sharing best practices of how OpenBOM services can help you manage both the design lifecycle and item lifecycle as well as to connect them in a single cohesive digital information thread.

Two Lifecycle Processes – Design & Item

Change management is a fundamental process every engineering and manufacturing organization must have in order to control information about the product, its design, bill of materials, and control the process of product maturing (from initial design to release and later to support and maintenance). While the process of product lifecycle management is connected and can take you through multiple stages, each of them represents separate, but connected elements of the lifecycle. In my article today, I want to focus on the following two lifecycles:

- Design (Files or design data) Lifecycle

- Item (BOM) Lifecycle

Design lifecycle reflects the design data (eg. CAD files or cloud documents) and their changes. I will speak about CAD files, but the same lifecycle logic can be applied to cloud CAD systems’ online documents. The fundamental element of the design data is a single part of the assembly that can be identified (eg. file name and/or part number) and changed over time. In such a case, the system will manage design integration (let’s call them versions) and these versions must be managed and controlled separately to provide a way for each version to provide a full list of files and related information helping Engineers identify what is included in the design. Such versions must be traceable and independent. Engineers must be able to make those changes as they’re making a progress with design towards initial design completion of consequent changes.

Item (BOM) lifecycle reflects a product structure that is created from multiple input sources (including design assembly-part information) but ultimately represents the way Bill of Materials (product structure) is created and managed. The foundation of the Item management process is an item and its revisions. The revisions are created as Item (and corresponded BOM or BOMs) are created and maturing. In such a way, Item revision (including BOM) can be created each time the product is changing from the initial BOM release to the next changes captured by Item (and BOM) revisions.

What is important is that these two lifecycles are independent and connected at the same time. Engineers could create 5 design iterations that will be reflected in 5 CAD file versions and, at the same time, only once to save Item and BOM and create a single BOM (Item) revision. A specific design file version is connected to a specific item revision, which ensures that design and BOM data are connected and can be traceable.

OpenBOM Services

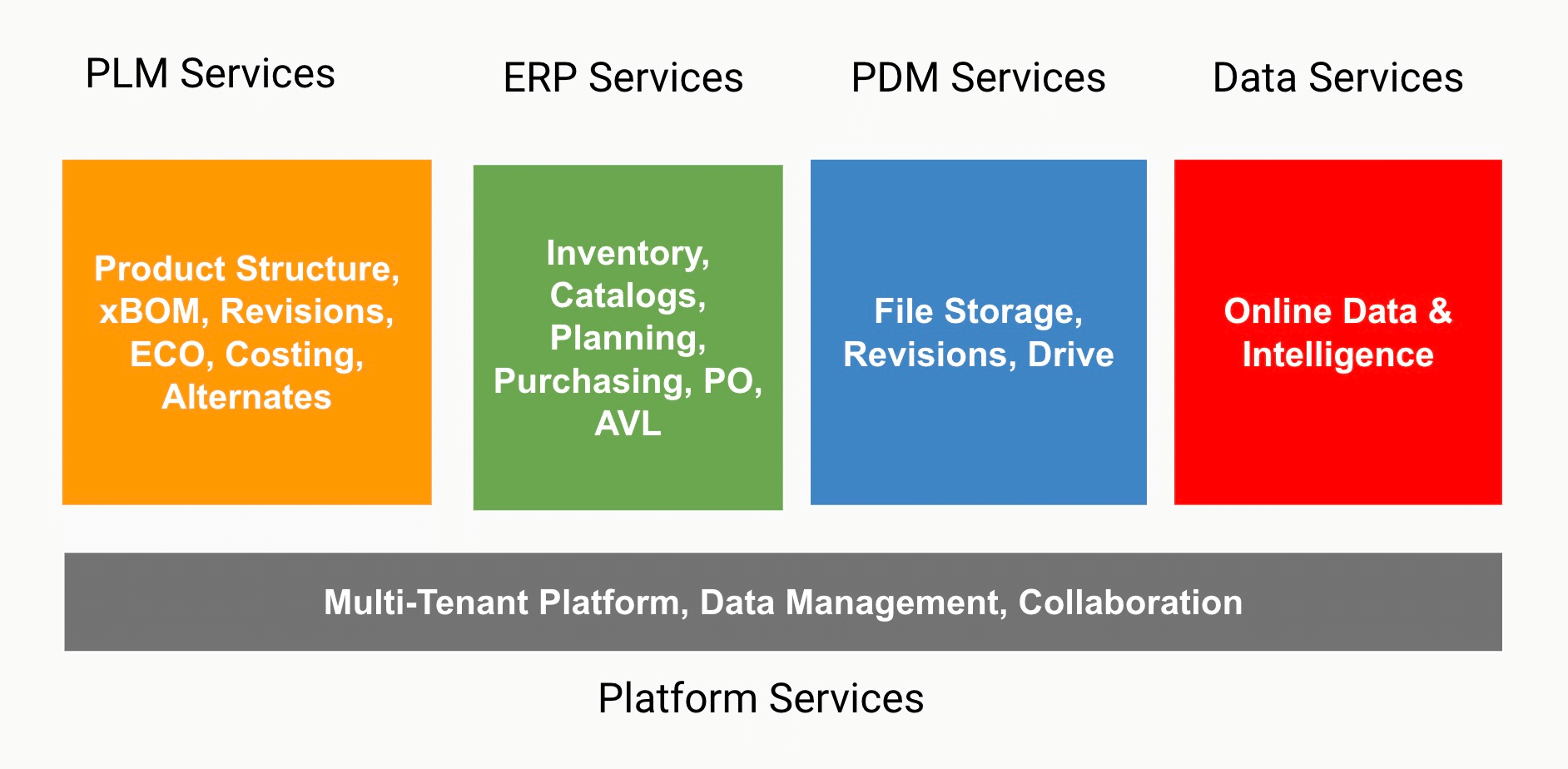

From the early days of OpenBOM development, we provided Item and BOM management functions (combined as BOM online service) to manage Items and BOM revisions. To continue OpenBOM expansion, we recently introduced Drive Service. In my article last week, I provided an overview of all OpenBOM services.

The picture above can give you an idea of what scope of services is covered by OpenBOM. In the context of this article two services (PDM and PLM) provide functions that are needed to manage design files and item lifecycle – PDM service and PLM service.

Drive (PDM Services)

The recent introduction of OpenBOM Drive allows an expanded lifecycle to start supporting CAD file storage, file collaboration, vaulting, check-in/out operations as well as 3D Viewer that can be used with these files.

OpenBOM Drive is a service providing virtual storage for all design files, captures their version automatically and manually (using check-out/in) commands as well as allows seamless data sharing and collaboration between multiple users. The design files in Drive can be referenced and connected to Items in OpenBOM catalogs. Watch the following video to get more information about how OpenBOM Drive works.

Check more information in the OpenBOM Drive review earlier in our blog.

Item & BOMs (PLM Services)

One of the first OpenBOM online services covers functions of item management (using OpenBOM catalogs) and BOM management. The data can be imported and created seamlessly, while the most interesting process in the context of the current article is the creation of items/BOM as well as the Item (BOM) revision process.

Such a process allows you to save item and BOM revisions connected to the design change process. Check out more about it in OpenBOM documentation:

As a result, OpenBOM allows you to consolidate both design versions and item revisions in a single connected data set and process.

Conclusion

OpenBOM cloud services create a scaleable and granular mechanism to manage various aspects of product information. OpenBOM PDM Service helps organize and manage design files as well as their version to reflect the design change process. Connected to the design changes, PLM Service gives you a mechanism to manage Items with all metadata and files and manage revisions and changes to control the release process and, by doing so, to manage the Item Lifecycle. Both Design Files and Item Lifecycle management are independent and connected at the same time. Engineers can be working on multiple design interactions, managing CAD files using PDM Service, and at a certain point creating (or updating) item data, saving item revisions, and freezing a released BOM structure. These two processes are intertwined and managed by independent and connected OpenBOM Services. The design files are connected to item data and you can explore and manage it using OpenBOM dashboards and other tools and services.

In my next article, I will come up with the videos and demonstrate how to manage design files lifecycle and item lifecycle (including CAD file versions and BOM changes).

In the meantime, REGISTER FOR FREE to OpenBOM to check out how OpenBOM can help you today.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.