Every manufacturing company is buying parts and outsource some work to contractors and suppliers. Although the process is pretty straightforward, it is not as simple as it might sound. Let’s be honest, the procurement doesn’t sound fancy as a design process, but if it is not done, your shop, team, or company will be delaying shipment or spending much more money for urgent and late orders.

How to run procurement efficiently? I discussed it with one of my colleagues looking for procurement solutions. It all depends on your business philosophy and practices. Some fast-growing shops and medium-size companies have a tendency to “think on the run”. But from my experience, a structured BOM costing approach can provide much better results. The Bill of Materials is a fundamental source of business information that can help. By recognizing the importance of BOMs from a purchasing and inventory control and costing perspective, you can achieve amazing results – to plan to purchase on time, ensure you have enough inventory to fulfill the orders, and to optimize lead time and purchasing cost.

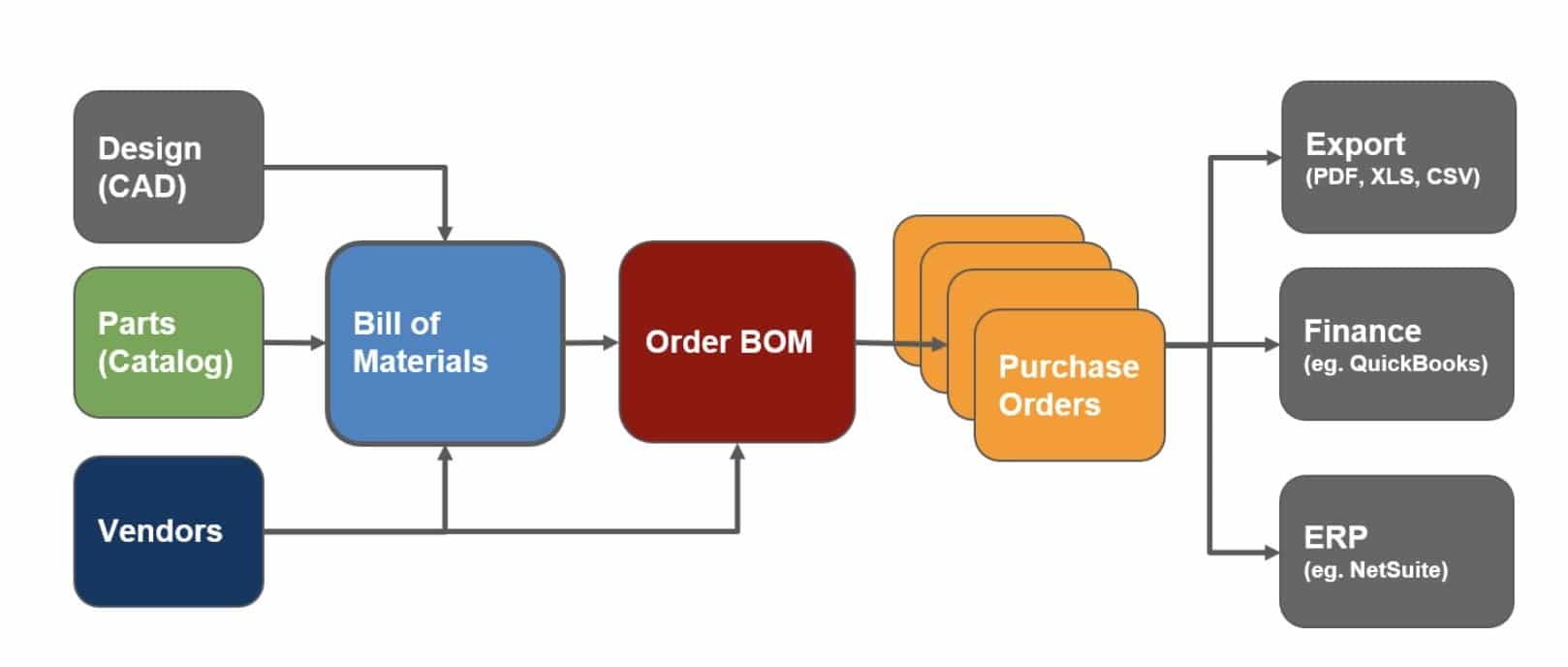

At OpenBOM we believe in setting up the databases on items to manage Parts, Materials, Labor, Purchased assemblies, etc. Everything is managed using OpenBOM distributed database, components are classified using OpenBOM catalogs and together with the Bill of Materials, it provides a single source of truth about what you design and manufacture. OpenBOM manages Parts, BOMs, costing, allows people to share data in a very efficient way. OpenBOM has very basic capabilities of management of vendors and purchasing, which we want to expand to provide a solution to mid-size manufacturing companies. We’re also looking at how to serve both sides – manufacturing companies looking for vendors and vendors looking at how to sell (think similar function you can find on amazon platform for multi-sourcing and advertising).

You can read more about OpenBOM Design to Purchasing the business process here – Introducing to Process and also more details here.

Conclusion

OpenBOM is a simple online service, but you need to spend a few minutes to get familiar with the basics – properties, catalogs, BOMs. I hope this video helped you. Please let me know if you liked it and how to improve it.

Best, Oleg @ openbom dot com.

Want to learn more about PLM? Check out my Beyond PLM blog and PLM Book website. Read OpenBOM customer reviews on G2 Crowd to learn what customers are saying about OpenBOM.

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.