Solidworks, being the long-standing de-facto standard in Mechanical CAD (MCAD), has set its position over time as engineers and designers continue to rely on its robust feature set, user-friendly interface, and widespread usage, despite its relatively mature age in the industry. Despite facing fierce competition in the realm of cloud-based design tools such as Onshape and Autodesk Fusion360, Solidworks remains a dominant player in the industry. This demonstrates its enduring popularity and effectiveness, as engineers and designers continue to rely on Solidworks for their daily tasks.

While Solidworks maintains its popularity as a leading Mechanical Computer-Aided Design (MCAD) software, it often reveals its inefficiency when it comes to downstream processes and Bill of Materials (BOM) management tasks. One of the primary drawbacks lies in its heavy reliance on traditional Windows, file-based, and Excel-centric paradigms. These approaches can lead to challenges in data management, collaboration, and version control, as well as hinder the seamless integration of BOMs with other enterprise systems.

As industries increasingly embrace cloud-based solutions and modern collaborative workflows, Solidworks can sometimes fall short in meeting the demands of today’s interconnected and data-driven environment. Its limitations in enabling real-time collaboration, centralizing data, and providing a holistic view of the product lifecycle can create bottlenecks and hamper efficiency in BOM management. This highlights the growing need for alternative solutions, such as cloud-based PLM platforms like OpenBOM, that offer enhanced collaboration, streamlined workflows, and integration capabilities to overcome the limitations of Solidworks in BOM and purchasing management.

Top 7 Challenges of Traditional BOM Management in Solidworks

Working with thousands of manufacturing companies using Solidworks we learned a lot about the shortcoming of BOM management with Solidworks and today, I want to share the top 7 challenges every engineer and manufacturing company are experiencing managing BOMs with Solidworks.

- Complexity in Managing Large BOMs: In large projects with thousands of components, managing the BOM can become overwhelmingly complex, leading to errors and inefficiencies. Especially when you need to create a BOM for multiple large assemblies with common parts.

- Lack of Real-Time Updates: If any changes are made to the design, exporting BOM to Excel and synchronizing changes is a big hassle. As a result, data may not always update in real time, causing inconsistencies between the design and the team of engineers and procurement people working with BOMs

- Difficulty in Handling Configuration-Specific BOMs: Solidworks configuration feature is super powerful, but resolving BOMs from configuration is not simple, system is often conflicting on part numbers, and managing parts with the same configurations can be super confusing. Managing different configurations of a part or assembly within the same BOM can be challenging. Changes in one configuration can inadvertently affect others, leading to errors.

- Inconsistent Part Numbering and Naming Conventions: Ensuring consistent part numbering and naming can be a challenge. This can lead to confusion and errors in the BOM. Users often rely on file names and additional attributes for Part Numbers, Managing them is a difficult process, and ensuring the uniqueness of Part Numbers is hard.

- Difficulty in BOM Comparison: Comparing multiple BOMs or revisions of the same BOM for differences and updates can be a tedious process. SolidWorks doesn’t provide an intuitive way to accomplish this.

- Problems with BOM Export with STEP, PDF, DXF, and other files: When exporting the BOM to other formats such as Excel, users might face issues with formatting, data consistency, and data loss. It is not easy to export data, including all the needed information, and generate all files typically attached to the BOM list.

- The issue with purchased assemblies and other exceptions: It is not simple to manage various complex rules when exporting BOM such as “exclude from BOM”, “hide/show”, purchased assemblies, etc. As a result, the BOM is not accurate and cannot be easily procurement.

OpenBOM For Solidworks

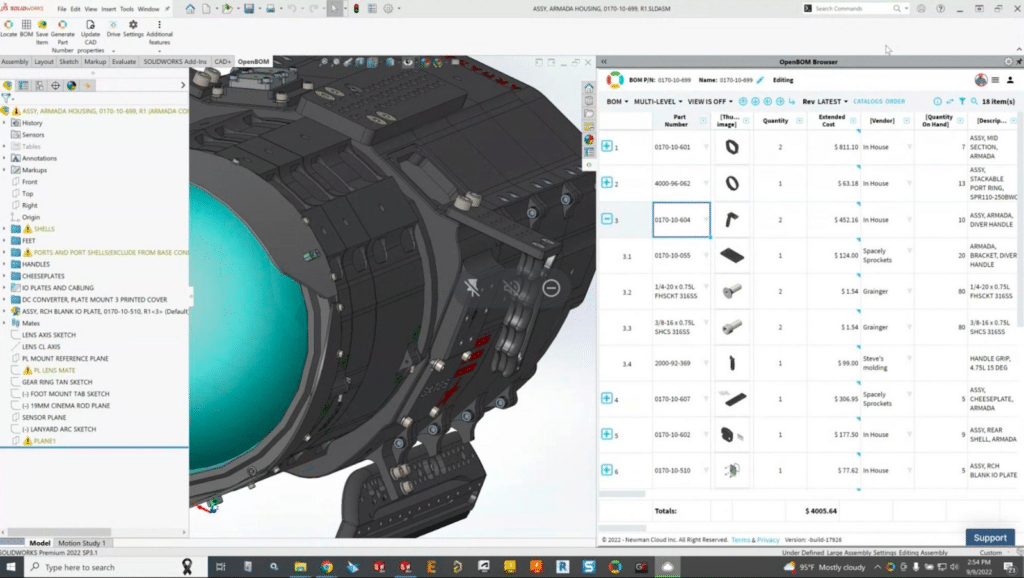

At OpenBOM we developed state-of-the-art integration with Solidworks ensuring seamless data handover between Soldiworks and OpenBOM environments. It gives a seamless user experience inside Solidworks, automatic data and file generations, thumbnails, support of different logical rules, and real-time updates.

In the following article we speak about 5 Things SolidWorks Users Must Try With OpenBOM. Here is a quick list:

- One-Click BOM for SOLIDWORKS. In other words, don’t make it think. …

- Automatic Part Number Generation. …

- Merge Bill of Materials for multiple assemblies. …

- Automatic Cost (and others) Rollup. …

- Automatic upload of files to the cloud and OpenBOM ZIP export.

Check them out with videos and hands-on practice (you can register for OpenBOM and start a trial in 5 minutes with any email. No credit card is required).

Conclusion:

Solidworks is great, but it doesn’t provide a digital user experience to manage data such as BOM, purchase process, data sharing, and collaboration. Manufacturing companies are looking for digital transformation and how to streamline information flow inside product development teams, contractors, and manufacturers.

Each time you manually export bills of materials to Excel, copy data from one place to another, update multiple Excel spreadsheets, or manually export files and collect them into zip packages you introduce mistakes that will cost your organization a lot of money, missed milestones, disrupted supply chain and unhappy customers.

Bringing digital tools like OpenBOM to your SolidWorks environment allows you to combine both worlds – mature CAD productivity and instant cloud-based BOM data management and real-time collaboration.

REGISTER FOR FREE and check how OpenBOM can help your projects immediately.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.