In the modern landscape of engineering and manufacturing, the concept of Digital Thread stands as a foundational pillar of Digital Transformation. It serves as the foundation for integrating the different enterprise systems and data sources. From Product Lifecycle Management (PLM) to Enterprise Resource Planning (ERP) and Manufacturing Execution Systems (MES). These are typical data sources for digital thread. Moreover, the influx of structured and unstructured data from various sources like databases, spreadsheets, and document repositories further accentuates the need for cohesive connectivity between these siloed systems to facilitate critical engineering processes such as change management and beyond.

Digital Thread Concept

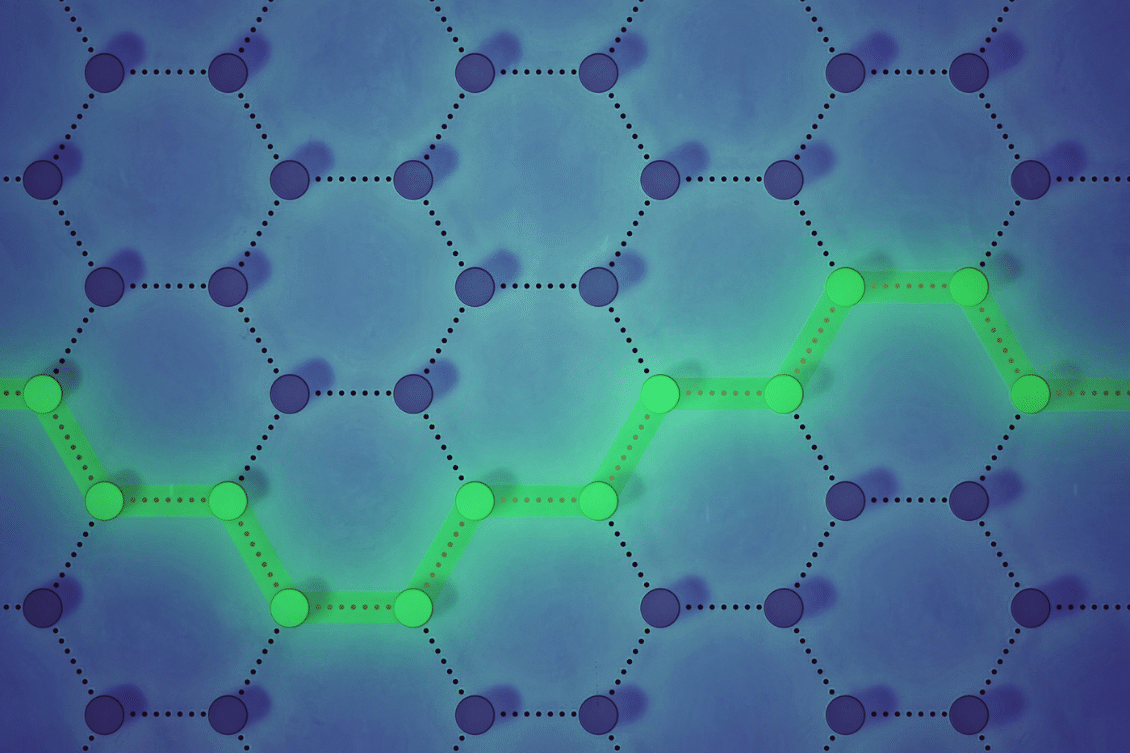

At its core, the Digital Thread is about knitting disparate systems and data sources together, enabling seamless traversal and exploration of data throughout the product life cycle. In the big picture, OpenBOM data architecture allows combining data from multiple sources and organizing data management in a way that all the information stays connected. The connectivity of OpenBOM which relies on multi-tenant data architecture and real-time collaboration plays the key role.

In this context, the architecture provided by OpenBOM emerges as a robust framework for realizing the full potential of the Digital Thread. It includes three fundamental elements: (1) Flexible data model; (2) Multiple BOM Types and Object Reference, and (3) Graph Model support. Let’s dig into all these elements separately. :

Flexible Data Model

OpenBOM’s architecture boasts a flexible data model that empowers users to create distinct object types (items) representing data across various stages of the product life cycle. Whether it’s requirements, engineering, manufacturing, planning, or maintenance, OpenBOM facilitates the representation and management of diverse data types across the entire spectrum of product development.

Here is an example of OpenBOM’s out-of-the-box data model every OpenBOM customer is getting access to. This model already has some elements of customization such as defining multiple catalogs, and more.

On top of this model, OpenBOM provides a mechanism of “custom objects and object reference link”. These mechanisms allow you to create any type of data and link attributes between different data objects.

Here is an example of the Requirements object in OpenBOM. In such a way, multiple object types can be created to manage multiple types of custom information.

Multiple BOM Types and Object References:

A new feature in OpenBOM is the ability to manage multiple BOM types, which enables the modeling of different product structures within a holistic digital Bill of Materials (BOM) representation. This innovation is augmented by object reference attributes, facilitating seamless connections between items across disparate data representations as and when required.

Such interoperability streamlines data flows and enhances collaboration across different stages of the product life cycle. The user experience is going to be really simple allowing you to select a specific BOM type.

In addition to that, OpenBOM Graph Navigation capabilities will allow you to move between multiple connected objects.

Graph Model Support, Traversal, and Analytics

Leveraging the power of graph database technology, OpenBOM’s architecture ensures efficient data connectivity and traversal. The underlying technology used by OpenBOM is Graph Database. Adopting a graph-based approach enables users to use powerful queries, and navigate complex data relationships with ease, fostering comprehensive analysis and facilitating data traceability for crucial operations like change management using graph data science.

One of the examples of powerful graph-based queries is to get “Where used” top-level queries straight out of every Item.

Conclusion:

The modern digital manufacturing environment necessitates the establishment of a robust Digital Thread to foster holistic data connectivity across the product lifecycle. OpenBOM’s architecture not only facilitates the seamless integration of diverse enterprise systems and data sources but also empowers users with the tools to perform in-depth analysis and ensure traceability throughout the product development journey. Embracing the Digital Thread paradigm facilitated by OpenBOM is paramount for organizations striving to thrive in the era of Digital Transformation.

If you’re interested in learning how to use OpenBOM to build a real-time digital thread for your company and beyond, please contact OpenBOM and we will be happy to assist you.

Best regards,

Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.