I’ve never in my life have had a manufacturing company tell me that cost management is not important to them. One of the most important elemental solutions OpenBOM provides that almost all users and customers are implementing is the way to manage and calculate the cost of the product, organize the list of parts to be purchased, and validate that the right price is used for the purchase orders.

The Problem

Trying to calculate the rollup cost in a spreadsheet is next to impossible. I can see two major headaches when you try to do so. The first is having a single place to store and manage cost information for parts and components. The usual approach is to create a BOM in Excel (or google sheet) and pull all the information there. But then a new product (and Excel came) and you need to do it all over again. The cost information is duplicated and you’re lost in many Excel files.

The second headache is the rollup. While BOM is structured as parts, sub-assemblies, and assemblies, the excel file is flat. To calculate cost per level and roll it bottom up is nearly impossible in spreadsheets.

OpenBOM solves both problems using a very simple and elegant solution. To make it happen, you need to get familiar with the basic OpenBOM data management capabilities.

Underlining OpenBOM Data Model

OpenBOM catalog is a database of all items that manage a single source of information about the parts (including cost) and is automatically used in all BOMs. No more duplications… OpenBOM formulas provide an out-of-the-box solution to rollup values (e.g. cost) calculated between multiple BOM levels.

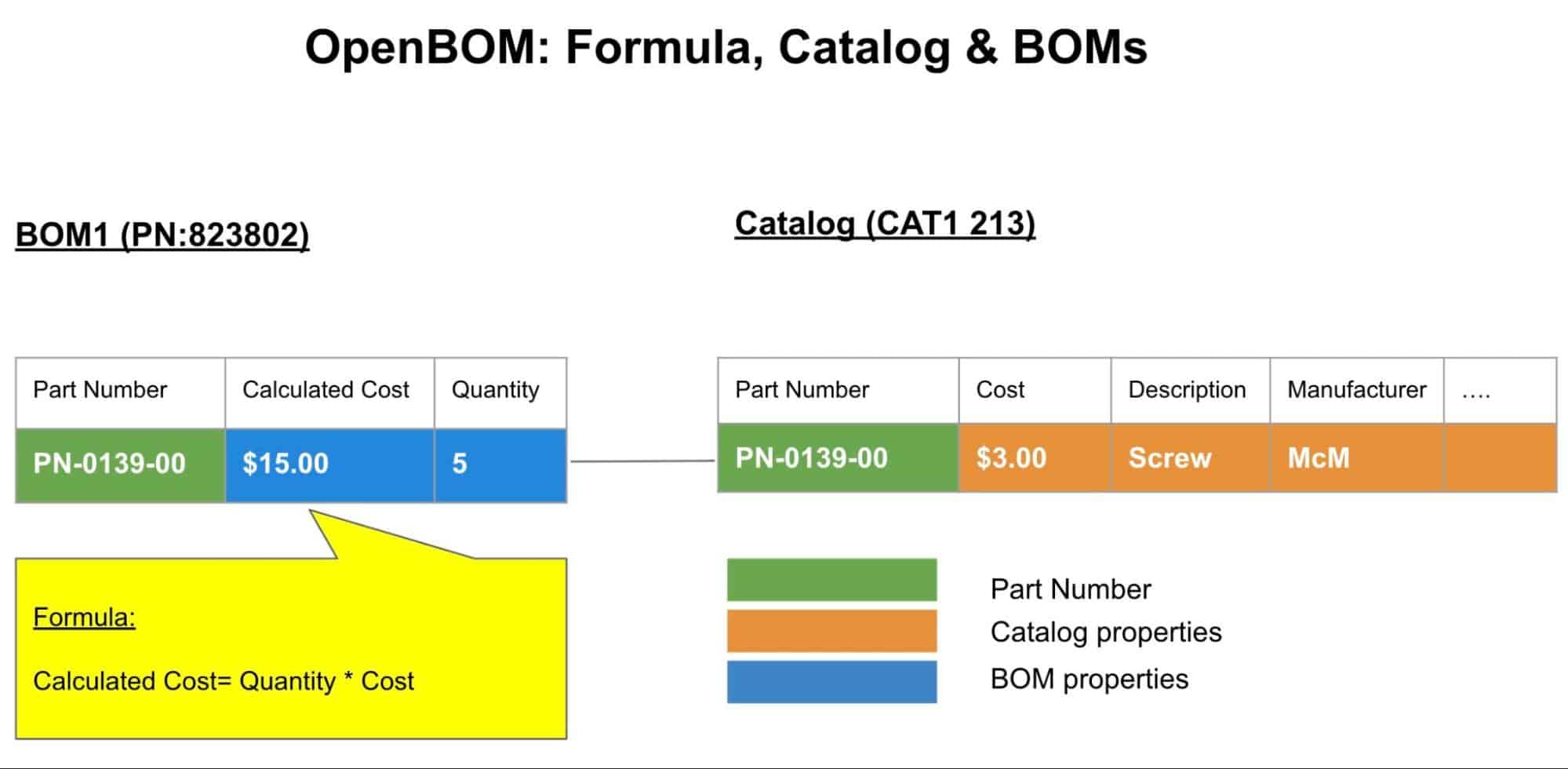

In the following picture, you can see how the OpenBOM data mechanism works between Catalog (Item Properties – Cost, Description, etc.), BOM (instance properties – Quantity, Calculated Cost), and connected Part numbers.

Rollups Calculations

Rollups Calculations

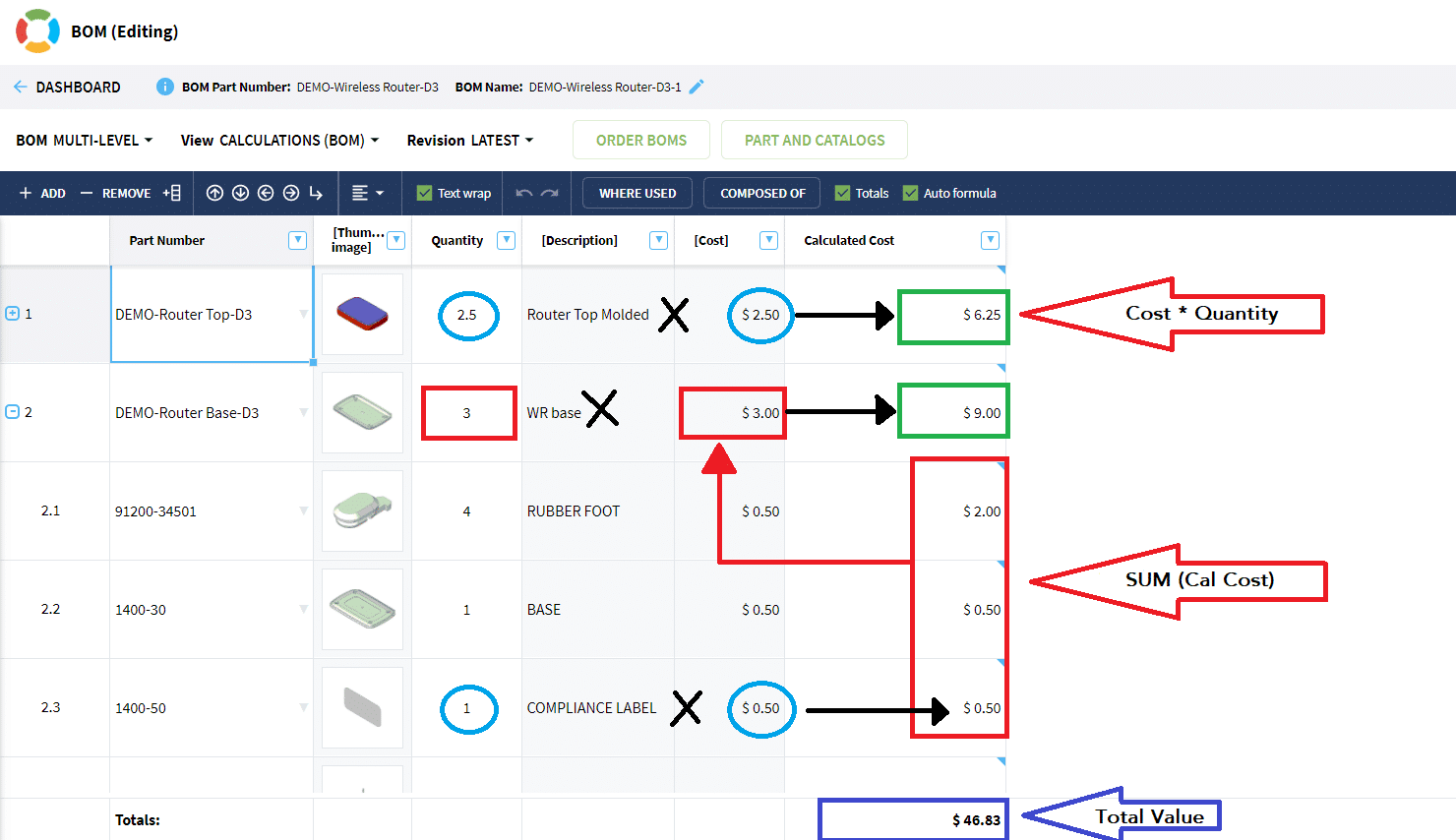

The following image explains the anatomy of calculations and rollup in OpenBOM. The formula mechanism calculates the totals on each level, propagates it up, multiply with the quantity and do repeats on the upper level.

In the end you will be getting a total rollup of the cost at all levels.

In the end you will be getting a total rollup of the cost at all levels.

Video Demo

The following video gives you a quick five-minute demonstration on how to set up a basic roll-up formula and get the total cost of your product assembly.

Conclusion

Rollup is a super powerful calculation feature that can be used flexibly in OpenBOM to help you calculate many properties (e.g. cost, mass, volume, etc). OpenBOM’s flexibility can be easily adapted to many different applications to make a total summary of the product characteristics. I hope this video helped you to understand OpenBOM’s underlying power.

If you’re looking to get some hands-on experience Register for FREE to create an OpenBOM account and start your FREE 14-DAY TRIAL today. You’ll be amazed at how easily OpenBOM helps you with calculation and rollups. I bet you’ll never go back to Excel again.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.