Throughout the life of your product, there will always be changes made to it. It doesn’t matter whether you are in early development or in mass production, changes will come up. And a key partner who will be part of these changes is your contract manufacturer (CM).

Role your CM Plays in the ECO Process

Your CM will play a pretty vital role in your ECO process. The simple reason for this is that you hire them to make your product. Since they have the production lines and the supply chain to make your product, they know what will work best in production.

There are a few reasons why changes are made to a product. They are the following:

- Customer Feedback

- Increase output to meet supply

- Reach economies of scale

- Eliminate a quality problem

Those changes that are made to decrease costs and increase the output can be driven by your CM. These changes can result in changing the method of processing, raw materials, and design.

Whatever the reason for the change is, communication and collaboration between your CM are key.

The ECO Process with your CM

Depending on whether you or your CM initiated the change requests, here are the steps to follow when a change is requested. If your CM is not requesting a change then it’s always good to keep them in the loop. Their feedback on the manufacturing feasibility and quotes will be important whether or not you approve a change.

ECR Review

The engineering change request (ECR) is circulated to all of the stakeholders. Your CM might make some modifications to this request as well.

ECO Creation

Once the ECO is created all of the product data will need to be updated to reflect the proposed change. To help confirm the requested change, the CM will need to provide both a prototype and a quote to the manufacturer.

ECO Review

A number of stakeholders who are responsible for approving or rejecting the ECO will make a decision. Usually, the CM is not involved unless the change affects the total output and not anything else.

ECO Approval

Once the change is approved, all of the stakeholders will need to be informed. The CM will also need to provide the implementation timeline that will be carried out next

Implementation

At this stage, your CM will need to make the necessary modifications to their processes to implement this change. This includes the following:

- Tool modifications

- Creation of new work instructions (WIs)

- Creation of new quality requirements

- Procuring new parts

How to Share this Data?

Most companies use Excel or spreadsheets to share and track their ECO process. While Excels are familiar to everyone around the world, they do very little to streamline your process and if anything, they add more chaos. If you manage the ECO process with Excel then you can expect the following:

- Unapproved changes to move into production

- Purchasing incorrect parts

- Working with outdated data

Working in Excel also provides no control over who is able to make changes. Anyone, including your CM, will be able to create a change to any part.

What’s the other Option?

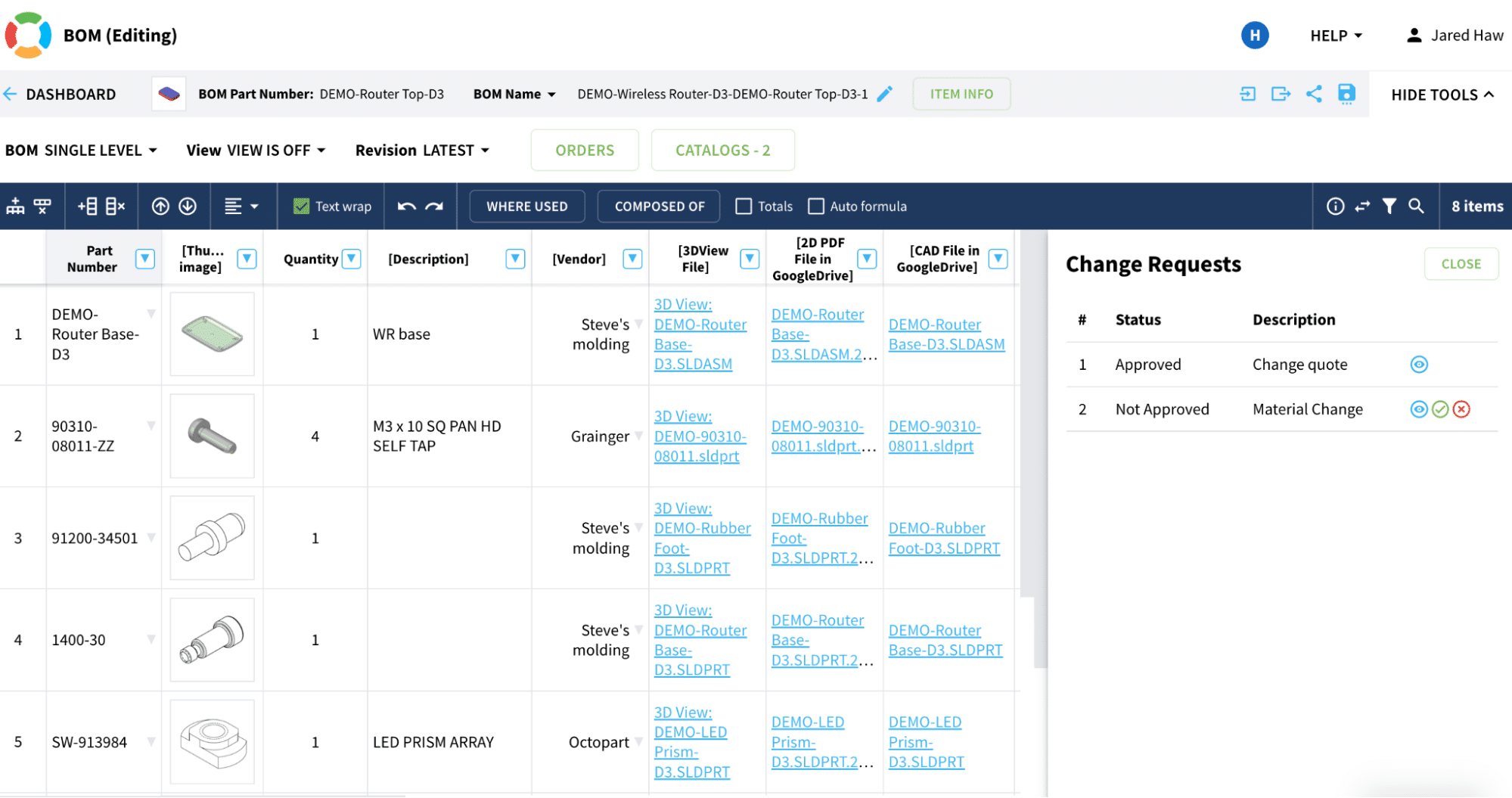

Setting an approval system for your ECO process is very important. Also, sharing your new product data with everyone else is just as important. The solution for this is a database that creates a single source of truth.

OpenBOM is a cloud-based PDM & PLM platform to manage your engineering and manufacturing data. Companies from startups to Fortune 500’s use OpenBOM to create a centralized database to bring in, store and manage their manufacturing data. With this infrastructure, users also use OpenBOM to streamline both their change management and PO processes.

If you need to improve the way you manage your data and processes, contact us today for a free consultation.

Regards,

Jared Haw

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.