For every engineering using the CAD system, the design of the product is a lot of fun. But, when the time comes to order parts…not really. You need to create a BOM or Part List, organize it in the right way, filter by components types, vendor, etc. It sounds like simple tasks, but when you have an assembly with thousands of parts, things can go ugly. Or take a long time.

One of the most painful things is purchased assemblies. Those pesky assemblies need to be present in your design as an assembly, but when you need to order them, it should come like a line item.

Thanks for one of OpenBOM users, I stumbled on Onshape article about order parts in Onshape community – How to combine assemblies into a single line Item in flattened BOM.

I thought, OpenBOM has something unique here and it can offer a great value to Onshape (and not only) users.

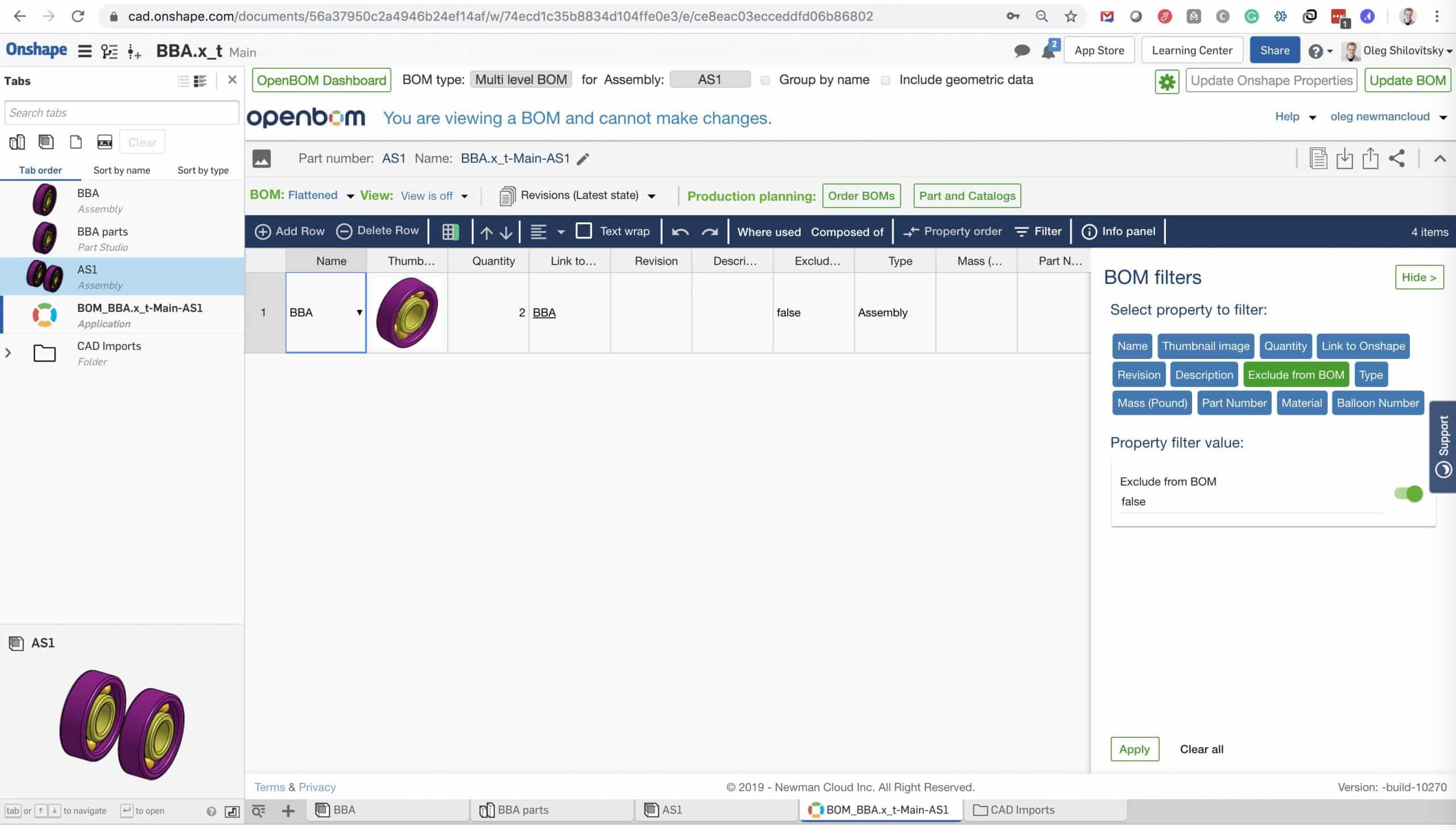

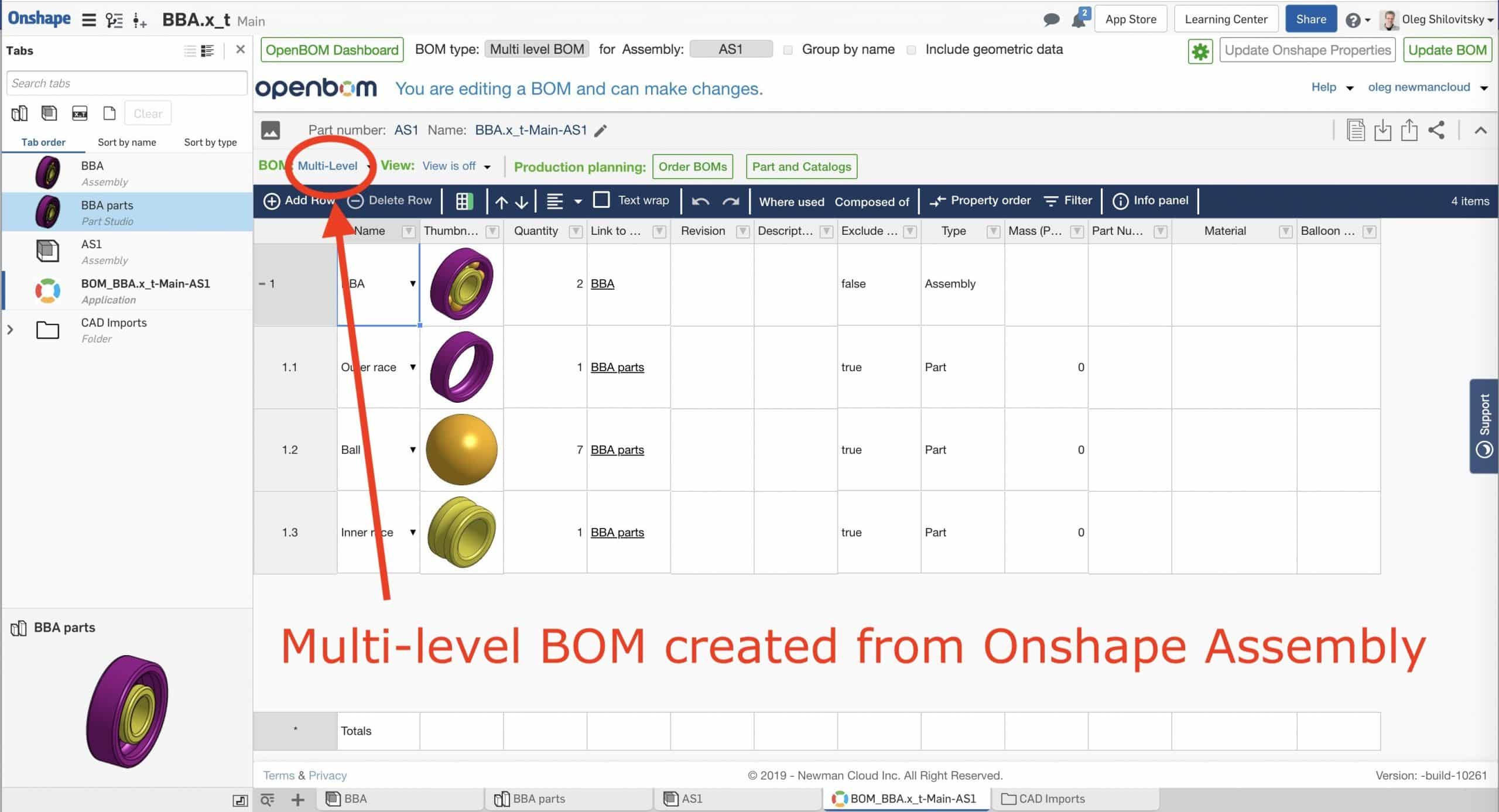

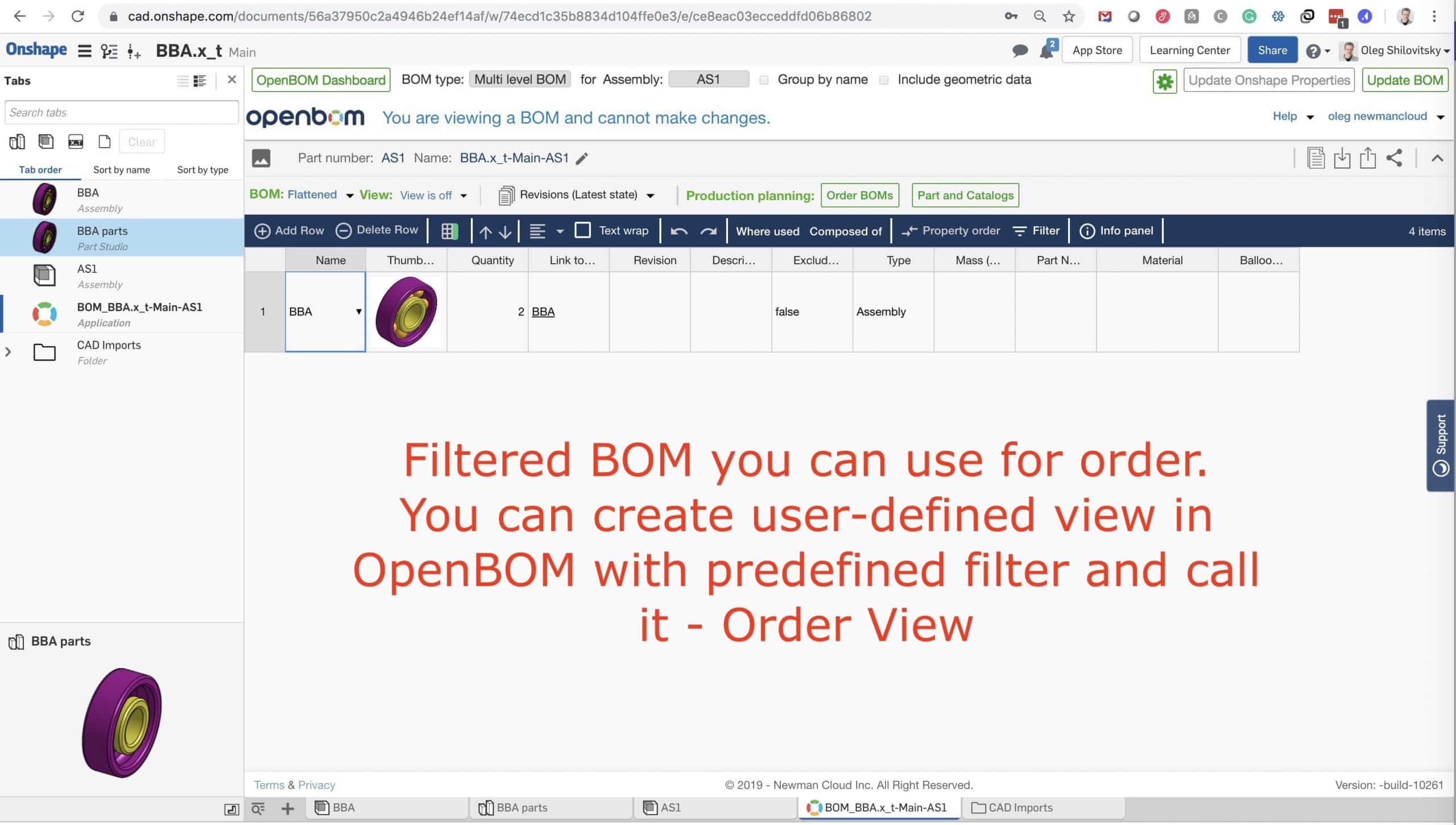

I created a simple test to demonstrated it. I pull a bearing assembly into my dummy project. OpenBOM app for Onshape allowed you to create a multi-level BOM. Don’t forget to pull value of “Exclude from BOM” when you configure OpenBOM template for Onshape. Besides that, the template is a great feature to organize your BOMs in a consistent way, so you won’t need to rebuild them all the time.

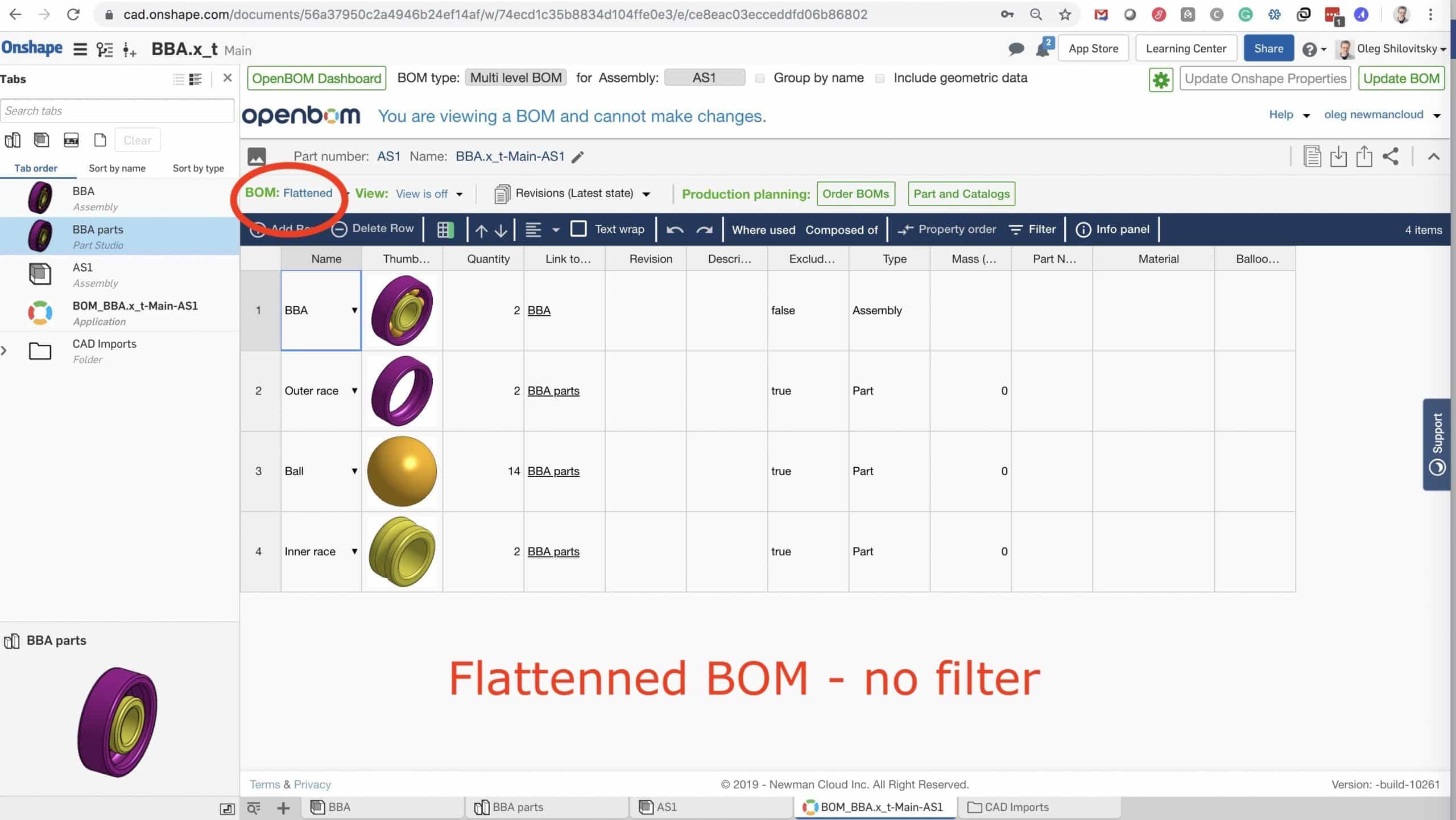

A quick switch to flatten BOM in OpenBOM gives you a quantity report across multiple levels in the assembly.

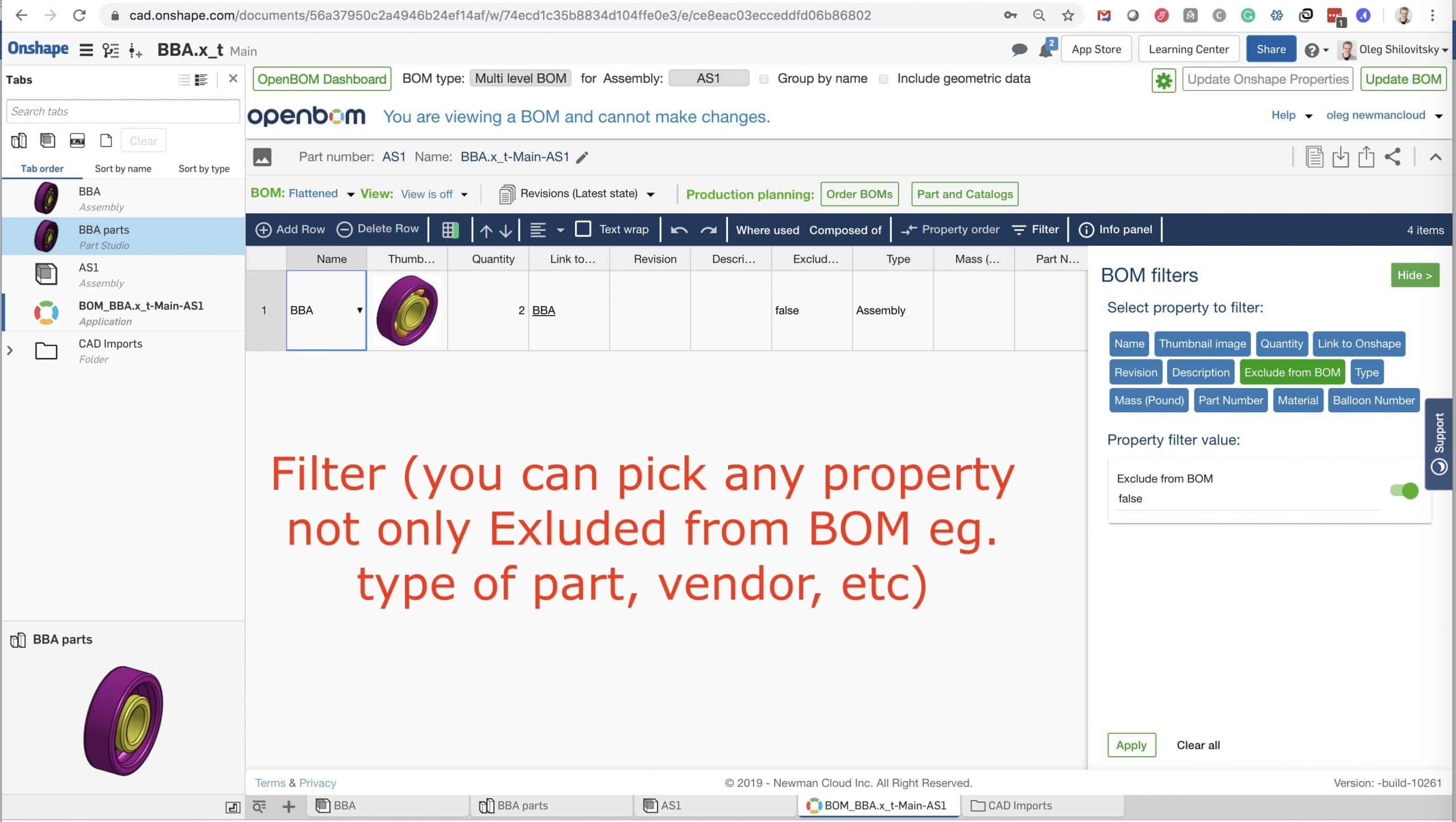

The remaining part is to apply a filter to get rid of the internal components of the bearing.

You can filter based on any properties- vendor, type of part, etc.

And here is the desired outcome – a single line for the order.

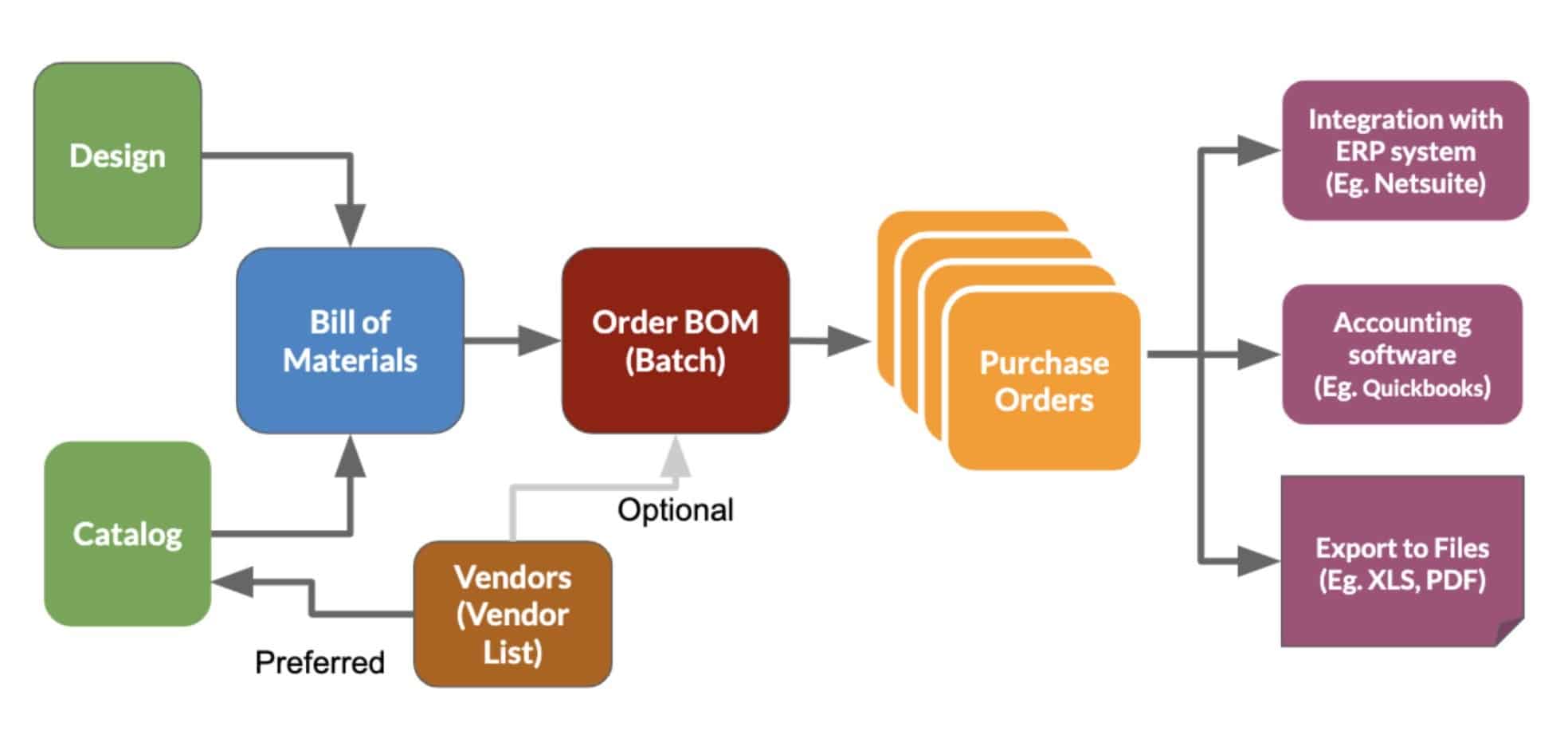

Keep in mind you can create an Order BOM in OpenBOM, manage Vendors and create purchase orders automatically.

Read more about it here – OpenBOM Production Planning Process.

Also, watch a video about how to create a purchase order for Onshape project.

Conclusion

OpenBOM helps you to get rid of pesky tasks of organizing your spreadsheets in Purchase Orders. It automatically generates BOMs from any CAD system, filter, slice and dice and creates purchase orders that can be sent to QuickBooks or other accounting software. Or… you can print it old fashion way and send via fax (we will come to replace faxes as well :)).

Best, Oleg @ openbom dot com.

Let’s get to know each other better. If you live in the Greater Boston area, I invite you for a coffee together (coffee is on me). If not nearby, let’s have a virtual coffee session — I will figure out how to send you a real coffee.

Want to learn more about PLM? Check out my Beyond PLM blog and PLM Book website

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.