If you’re using Autodesk Eagle for your electronic PCB designs, you know that one day you need to create Bill of Materials to plan production, estimate cost and making purchases. Eagle is a very flexible environment and you can use ULP programs to do almost everything you want. So you export BOM to Excel can be an easy function (such script already exists).

But here is the thing. You also know that manage all this stuff in Excel you need to hire Chief Excel Officer and it will be hard. Excel is limited in many ways. When you need to calculate the cost, mass or plan purchasing, Excel is not a good tool. Also, sending Excel and Drawings to a shop or to a contract manufacturer is prone to many mistakes.

OpenBOM is coming to help you. To make it really easy, OpenBOM created integrations with all CAD systems allowing you to collect information engineers and organize it in a way that allow you to manage data about all your parts.

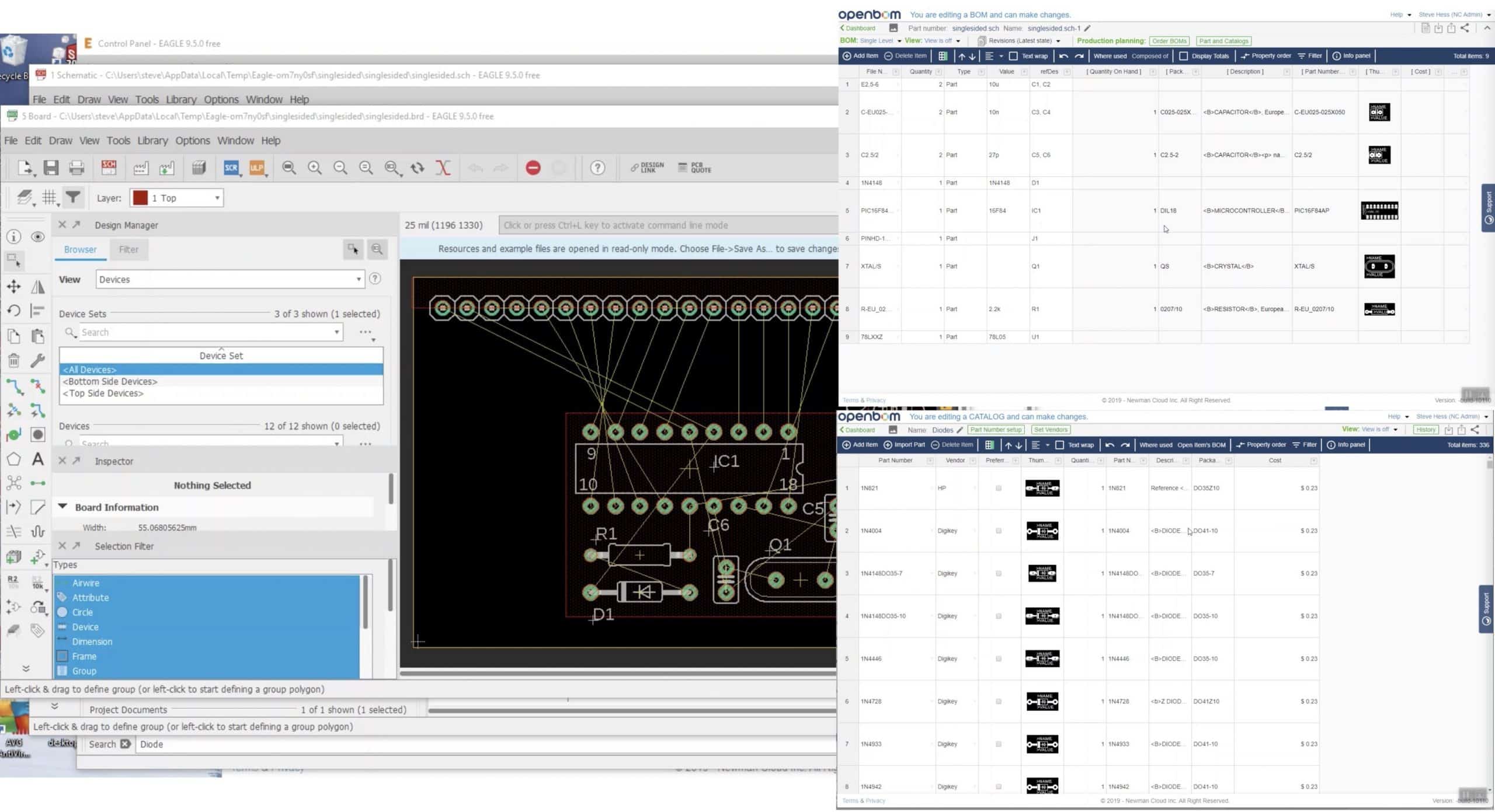

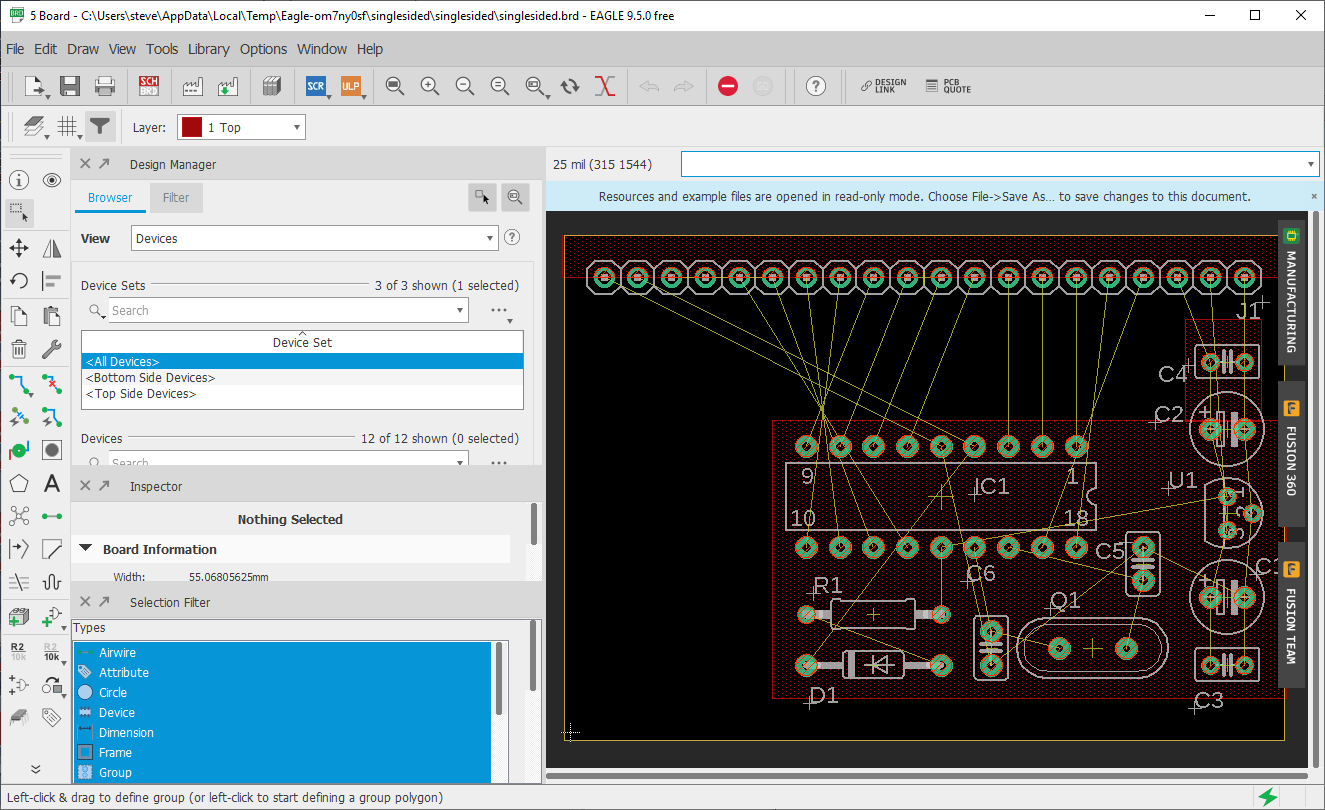

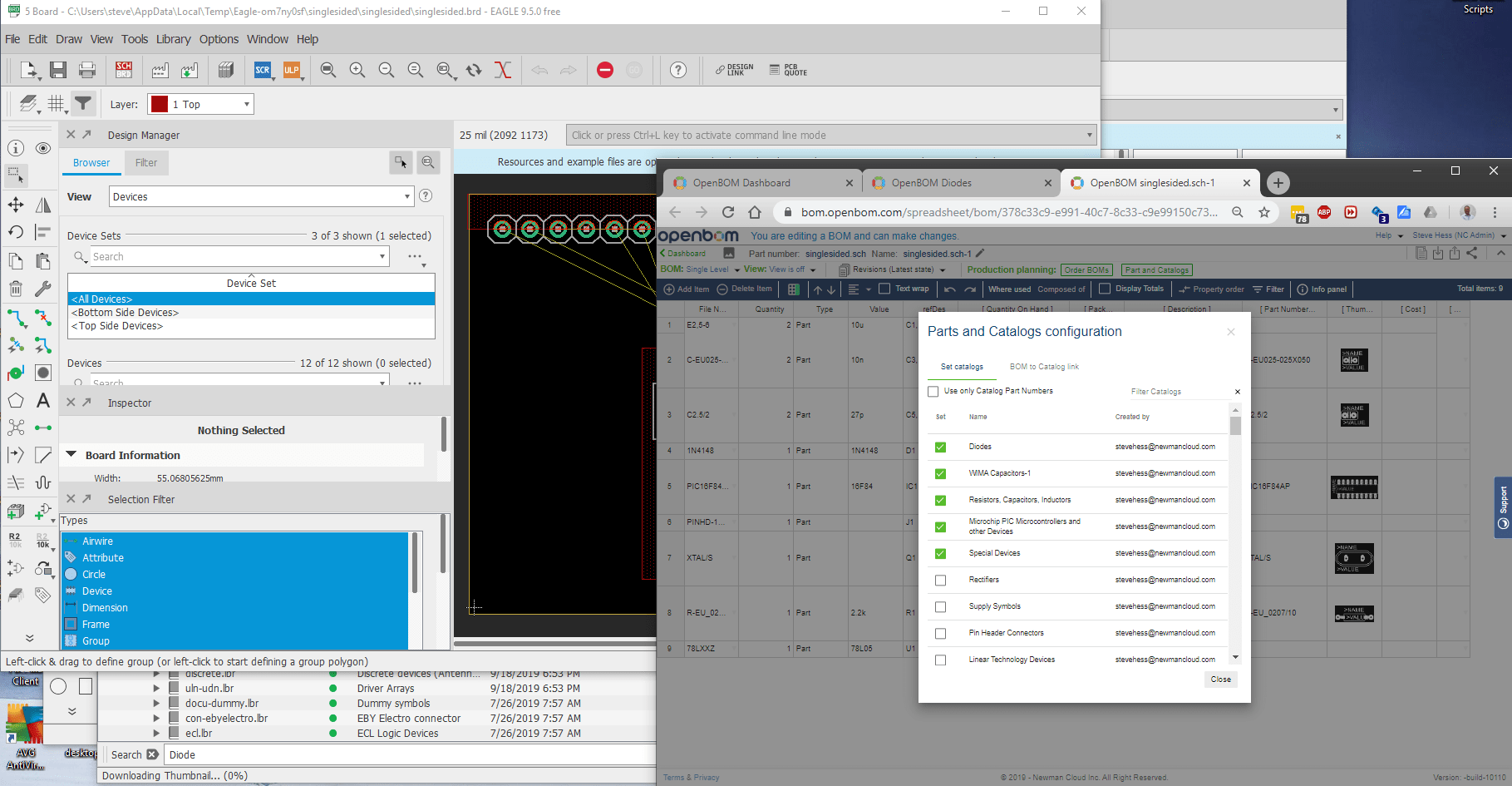

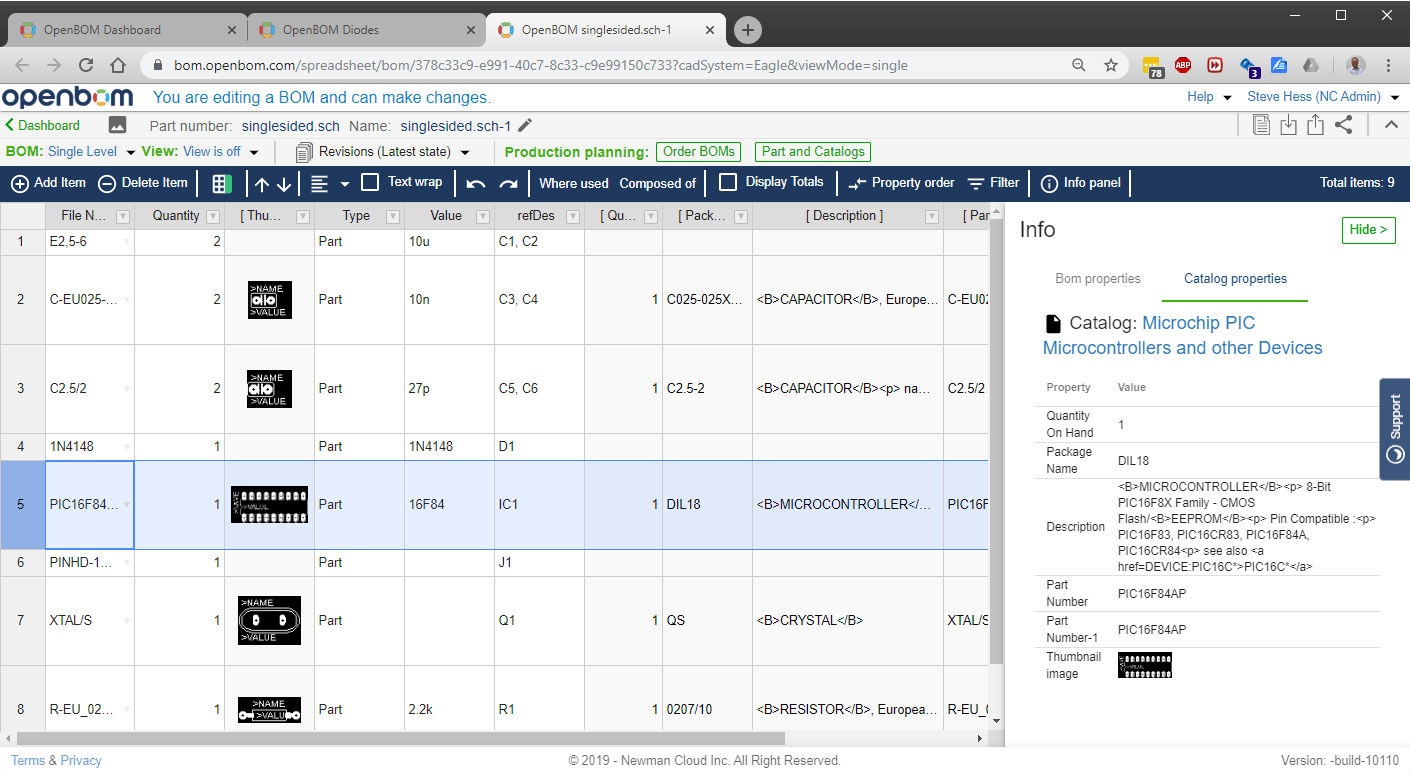

Below, you can find a typical scenario to follow in order to organize the data and create a first BOM from Autodesk Eagle. OpenBOM is using a system of catalogs (think database of all parts and components) and Bill of Materials (usages). A catalog(s) is good to create a single version of the truth about parts, suppliers, manufacturers, compliance, cost, etc. Bill of Materials is a perfect place to manage a specific BOM including instance properties (eg. Reference Designator, Quantity, etc.)

In the following video below, OpenBOM Director of User Experience, Steve Hess will be taking you into 3 minutes journey how to create a catalog from Autodesk Eagle libraries and then combine it together with Bill of Materials extracted from schematic design.

Below a few screenshots from the video:

Conclusion

Managing the Bill of Materials is an extremely important task in your journey from initial design to first prototype manufacturing and later to scale your production. To establish a database for your product components, to count parts and store baselines of your design helps to create accurate planning, communicate with contractors and manage many other related design and manufacturing tasks. OpenBOM allows you to capture data about BOM and keep related information closed, but not messed up with multiple Excel files.

OpenBOM Add-In for Autodesk Eagle is FREE and it is available with any OpenBOM subscription today.

Best, Oleg @ openbom dot com.

Let’s get to know each other better. If you live in the Greater Boston area, I invite you for a coffee together (coffee is on me). If not nearby, let’s have a virtual coffee session — I will figure out how to send you a real coffee.

Want to learn more about PLM? Check out my Beyond PLM blog and PLM Book website

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.