This is the first article in a new series called “OpenBOM: Getting Started 2026.”

The idea behind this series is simple: explain, step by step, how modern teams can organize product data in a way that actually works in 2026—without marketing language, without theory for theory’s sake, and without assuming you are starting from a clean slate.

Most engineering and manufacturing teams aren’t starting fresh. They are starting with CAD systems that have been in place for years, spreadsheets that quietly became critical infrastructure, ERP systems that run the business, and people who have learned to work around gaps rather than eliminate them. This series is about working with that reality, not pretending it doesn’t exist.

We’ll start at the foundation: the Digital BOM, what it really means today, why it exists, and how OpenBOM approaches it.

Products Are Getting More Complex, Whether We Like It or Not

It’s almost unnecessary to say this, but it’s still worth stating clearly: products are no longer just mechanical assemblies.

Even relatively simple products today combine mechanical parts, electronics, firmware, software configurations, supplier-specific components, cost structures, compliance data, manufacturing constraints, and service requirements. Each of these elements evolves at a different pace, often owned by different teams, sometimes even by different companies.

What hasn’t kept up is the way this information is organized.

In many companies, the “BOM” still means a spreadsheet exported from CAD. Electronics data lives in a different system. Software versions are tracked somewhere else entirely. Cost is calculated manually. Supplier information is copied and pasted. Manufacturing engineers recreate structures downstream. Service teams build their own lists later. Everyone does their best, but everyone is working from a partial view.

This is not a people problem. It’s a structure problem.

A modern product needs a digital structure that can hold all of this information together, without forcing everything into a single rigid format or tool. That’s where the idea of a Digital BOM comes in.

What a Digital BOM Really Is (and What It Is Not)

A Digital BOM is not just a better spreadsheet. It’s not a report you generate at the end of design. It’s not a static file you email around.And it’s not something that belongs to only one d epartment.

A Digital BOM is a living product structure that connects everything you need to know about a product in one place:

- Mechanical and electronic components

- Files and documents

- Links to CAD, PCB, drawings, specifications

- Cost and supplier information

- Manufacturing and sourcing context

- Maintenance and service perspectives

The key word here is connects.

The value of a Digital BOM is not in listing parts, it’s in preserving relationships. Relationships between parts and assemblies. Between parts and suppliers. Between parts and files. Between engineering intent and manufacturing reality. Between revisions and decisions.

Once those relationships exist digitally, teams can stop rebuilding context over and over again.

Where OpenBOM Fits In

OpenBOM was built around a simple but often overlooked idea: product data already exists and our job is to connect it, not replace it.

Most teams don’t want to abandon their CAD tools, ECAD systems, spreadsheets, or ERP platforms. They want those tools to work together.

OpenBOM brings product data together from multiple sources:

- MCAD systems

- ECAD and PCB tools

- Excel spreadsheets

- Files stored in folders or cloud drives

- External references and links

Instead of forcing everything into a single authoring environment, OpenBOM acts as a digital backbone that connects and organizes this data into a coherent product structure.

The Digital BOM becomes the place where all of this information meets.

Connecting Mechanical and Electronics Data in Practice

One of the easiest ways to understand the value of a Digital BOM is to look at mechanical and electronics data side by side.

Mechanical engineers work in assemblies, hierarchies, and configurations. Electronics engineers work with schematics, PCB layouts, and component libraries. Historically, these worlds meet late – often through a spreadsheet that tries to flatten everything into a single list.

OpenBOM allows these domains to remain distinct where they need to be, but connected where it matters.

For example, mechanical structures coming from SolidWorks can be combined with electronics data coming from Altium into a single Digital BOM. You don’t lose the structure of either domain. You don’t force electronics into mechanical hierarchies or vice versa. Instead, you get a unified view that reflects the real product.

This matters not just for engineering, but for everyone downstream, procurement, manufacturing, operations, and service, who need to understand the product as a whole, not as disconnected fragments.

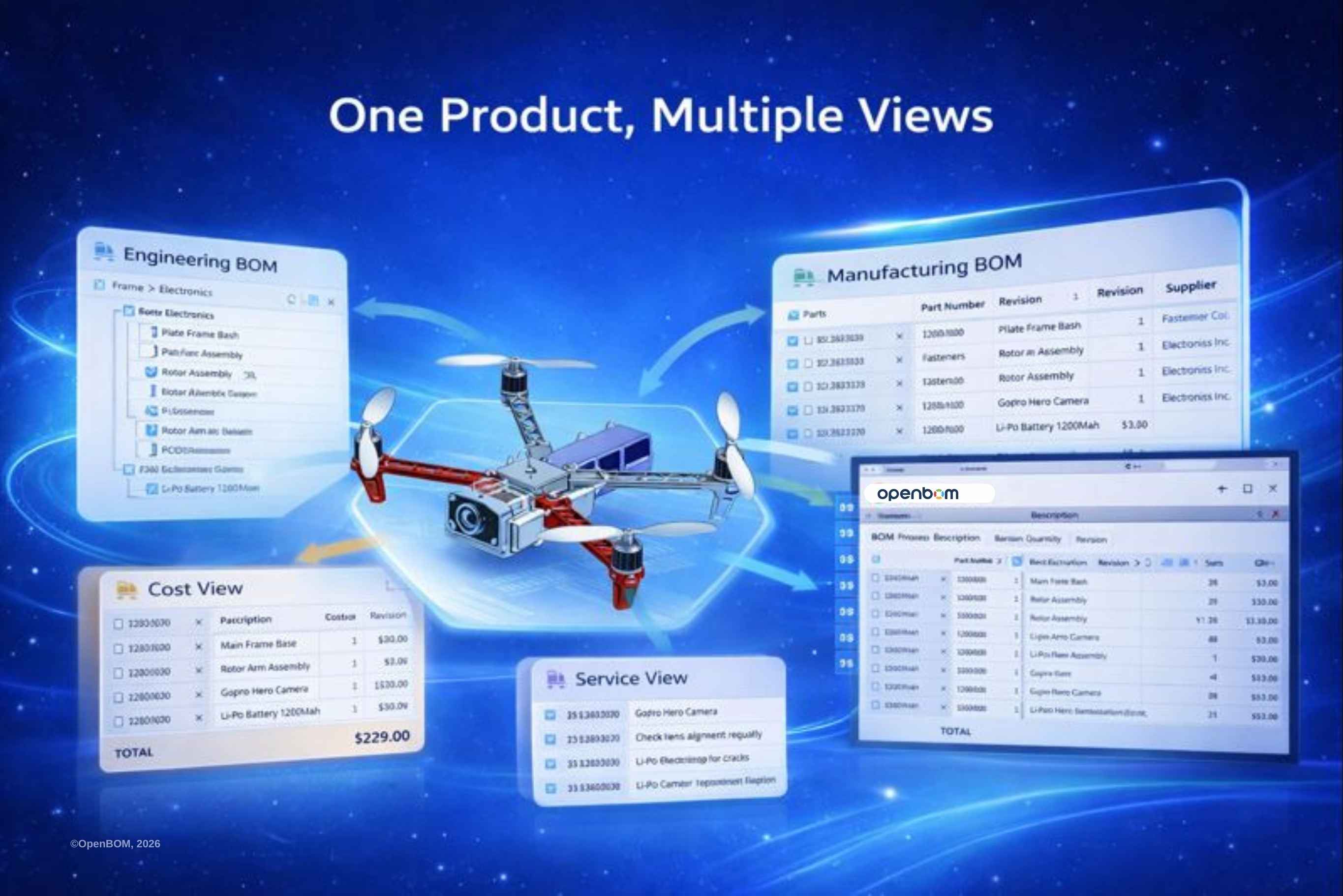

One Product, Multiple BOM Views

Another common source of confusion is the assumption that there is one correct BOM.

In reality, different teams need different views of the same product data.

OpenBOM supports multiple BOM types and views because product data is inherently multi-dimensional:

- Multi-level BOMs preserve structure and hierarchy, making it easier to understand how a product is built.

- Flattened BOMs simplify navigation and analysis, especially for costing, sourcing, and procurement.

- Engineering BOMs (EBOM) reflect design intent and engineering structure.

- Manufacturing BOMs (MBOM) reflect how the product is built, sourced, and assembled.

- Customizable BOM types (often called SOBOMs) allow teams to create views tailored to specific workflows – service, installation, projects, or customer-specific configurations.

All of these views are built on the same underlying Digital BOM. That’s the critical point.

You are not duplicating data. You are not maintaining parallel spreadsheets. You are looking at the same product through different lenses.

Why This Matters Beyond Engineering

It’s tempting to think of BOMs as an engineering artifact, but the real impact of a Digital BOM shows up when data flows beyond engineering.

When cost is connected directly to parts, estimates become faster and more accurate. When suppliers are linked to components, sourcing decisions are grounded in reality.When manufacturing sees the same structure as engineering, adapted to their needs, handoffs improve.When service teams can trace what was built, where it was used, and which revision matters, support becomes proactive instead of reactive.

The Digital BOM becomes a shared reference point across the product lifecycle.

Video Walkthrough: Introduction to OpenBOM Digital BOM

This article is intentionally paired with a video walkthrough. Reading about Digital BOMs is useful, but seeing how data comes together makes the concept tangible.

🎥 Video: Introduction to OpenBOM Digital BOM

This walkthrough shows how OpenBOM brings mechanical, electronics, and other product data together into a single Digital BOM.

You’ll see:

- How data from tools like SolidWorks and Altium is connected

- How different BOM views work in practice

- How OpenBOM helps teams navigate complex product structures without losing context

If you are new to OpenBOM, I recommend watching the video first and then coming back to the article. The concepts will click faster once you’ve seen them in action.

What This Series Will Cover Next

This first article is about orientation – understanding what a Digital BOM is and why it matters.

In the next posts in the “OpenBOM: Getting Started 2026” series, we’ll go deeper into practical topics, such as:

- How OpenBOM can manage CAD files (PDM)

- How OpenBOM can manage inventory and help organize orders

- How OpenBOM helps teams collaboration, tasks, management, and ordering

- How to integrate with ERP systems

- How Digital BOMs become the foundation for more advanced automation and AI-driven scenarios

Each article will build on the previous one. No big jumps. No assumptions that you already have everything perfectly organized.

Conclusion and a Final Thought

The shift from static BOMs to Digital BOMs is not about tools – it’s about clarity.

As products become more complex, the cost of misunderstanding grows. Teams spend more time reconciling data than making decisions. A Digital BOM doesn’t eliminate complexity, but it makes complexity visible and manageable.

That’s the foundation we’ll keep building on throughout this series.

If you’re just getting started with OpenBOM, this is the right place to begin.

REGISTER FOR FREE and check this out.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.