Releasing a new product into the market can be an exciting, yet nerve-wracking experience. A lot of time, effort, and resources go into developing a new product, and a successful release can mean the difference between the growth or decline of a business. However, there are many factors to consider when it comes to product releases, such as timing, marketing strategy, pricing, and customer feedback.

PLM and product data management are core systems to support product lifecycle management processes during the development and later production planning and manufacturing stages. Moving between lifecycles from PLM to manufacturing BOM and downstream to material requirements planning is an extremely complex process that requires a transformation of computer-aided design (CAD) design to engineering BOM, adding raw materials and other non-CAD items. This is where the digital thread begins.

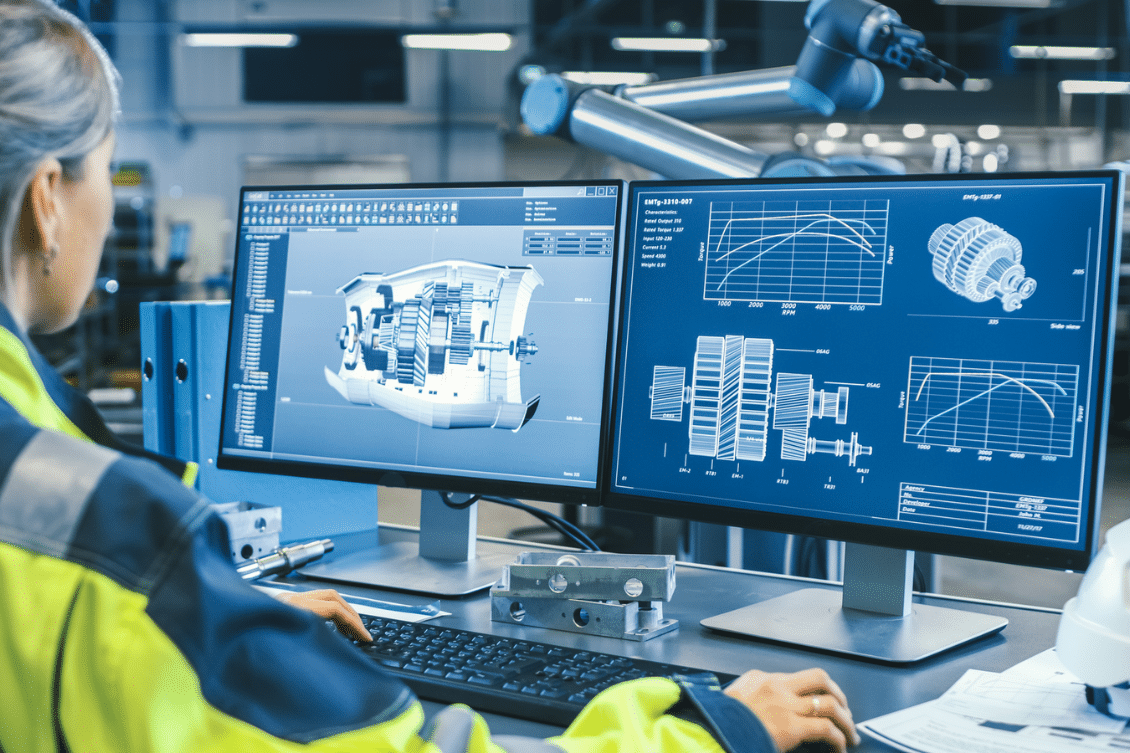

Today I want to talk about the nuts and bolts of the release process. I’d like to talk about the process where everyone is getting confused – CAD design changes, items, BOMs, versions, and revisions. It doesn’t take a long time in any conversation about revision and change management process to get in the weeds of what is version, revision, what happens when you change the design (CAD file), and how to revise product structure. Anyone who was in these conversations knows how complex it could be and how much confusion it can bring.

Release Process – Design vs EBOM Lifecycle

Let’s start from the beginning. Check the following article Product Release Best Practices. I always recommend checking and learning about the dual nature of changes. One lifecycle is for design and a separate lifecycle is for items and BOMs (product structure). So, read the article and remember the difference between design and BOM lifecycle. The picture below outlines nicely the story.

You can ask why the separation is needed. Why we cannot just manage document changes once they are ready to release them? This is a very legitimate question. Companies were doing it for a long time using old PDM systems that they called “PLM”. The document-driven process was ok until we moved to the next level of modern product data management and business systems development.

Multidisciplinary Design and Product Release

Every product these days (with a small exclusion) is a complex system that requires complex PLM to manage. The complexity of product data management is skyrocketing. Companies are running multiple design teams working on different systems, mechanical, electronics, software, etc. Supply chain management is also a problem and must have clear access to product release information. This is where product lifecycle management theories hit the road and demand answers.

The recommended best practice is to separate design changes from EBOM (product structure) changes. You might have mechanical, electronics, and software engineers working in parallel without blocking each other and later (one day) coming to create a common product structure that represents the entire PLM representation with the complete set of up-to-date information.

Dual Model for CAD/BOM Changes: Design Versions and Item Revisions

The following picture demonstrates a simplified diagram of how changes can happen in parallel in both design and engineering structures. You can see steps 1-4 and during these steps, changes are happening in parallel in design and EBOM.

For clarity, we call design changes – versions and item changes – revisions. The names are less important, but the separation of these two processes is extremely important for understanding. Because changes are not happening at the same time and, even more, changes in CAD design don’t mean immediate changes in Item/BOM and vice versa.

Design (CAD) – Item (BOM) Changes Traceability

One of the most important questions is how to trace changes between CAD and Items. The traditional approach of most CAD (and PDM) implementations is to have the “Revision” property placed in CAD design. Usually, it is an attribute in CAD documents (eg. Parts or Assemblies) that maintenance by engineers manually or assigned and managed by PDM implementations.

To maintain traceability between CAD (version/revision) and Item (revision), we recommend keeping both CAD (version and revision) and Item Revision information in the Item.

In the coming releases of all OpenBOM CAD integrations, we will provide automatic support for referencing CAD Versions/Revisions from Item objects to support revision traceability in BOM changes. Stay tuned for more examples and videos.

Conclusion:

Managing of changes in both CAD design and Item/BOMs is a complex process. The complexity is increasing in modern products because of the multi-disciplinary nature of the products (mechanical, electrical, software components) as well as because of the work done in parallel by engineering and manufacturing planning teams. To maintain changes and revision traceability we recommend using CAD version/revision reference in Items. OpenBOM flexibility data model allows you to organize these reference fields. Updates coming in all CAD add-ins will provide automatic support for these data fields.

REGISTER FOR FREE and start a free 14-day trial to explore OpenBOM.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.