In this article, we explore the story of Xtend AI, a company developing mobile intelligence and robotic platforms. With a mission to revolutionize robotics, Xtend AI turned to OpenBOM to streamline their development process, enabling them to design and manage complex robotic systems efficiently.

The idea of Xtend AI is to build a series of robots that can be configured by customers to perform tasks and operate autonomously in different environments.

Through a combination of robust data management, seamless integration, and innovative features, OpenBOM empowered Xtend AI to focus on innovation while optimizing their operations. Here are a few highlights of how OpenBOM supported Xtend AI‘s journey:

VIDEO Interview with David Rubli, Head of Mechatronics R&D

Listen to the story of David Rubli about his experience of using OpenBOM and read some highlights from this story below.

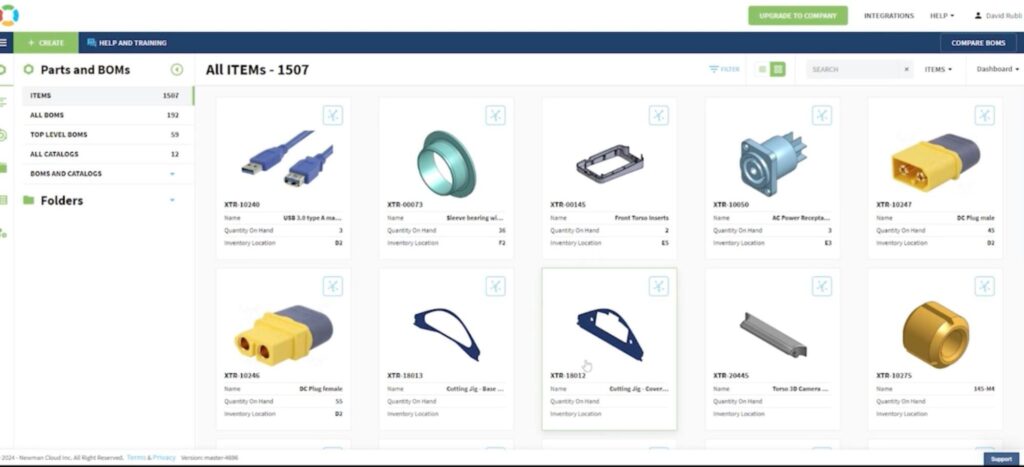

Robust Digital BOM Management

Xtend AI leveraged OpenBOM’s flexible and dynamic Bill of Materials (BOM) capabilities to manage their product data. Whether working with flattened or multi-level BOM structures, OpenBOM provided the agility needed to represent the complexity of Xtend AI‘s robotic platforms. This ensured clear visibility into the product hierarchy and components, which is critical when managing cutting-edge robotics systems.

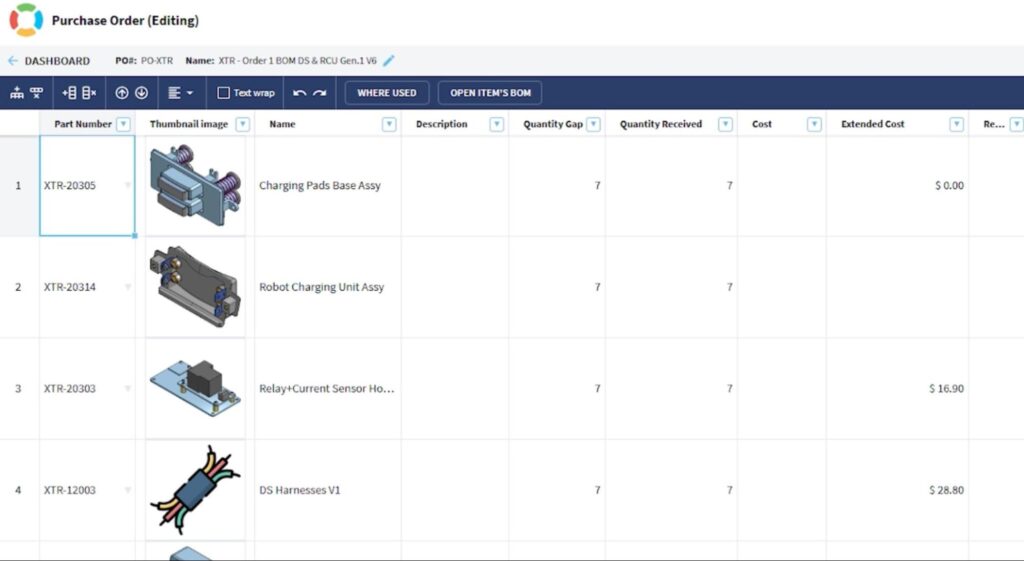

Data Calculations and Formulas

Engineering innovative products requires precise calculations and real-time data accuracy. Xtend.AI utilized OpenBOM’s formulas and calculation capabilities to automate processes like cost estimation, weight analysis, and performance metrics. By embedding these formulas directly into their BOMs, Xtend AI streamlined cost rollup, saving valuable time and reducing errors.

Seamless Integration with Onshape

OpenBOM’s integration with Onshape allowed Xtend AI to synchronize CAD data with BOMs effortlessly. This integration ensured that design changes were automatically reflected in the BOM, eliminating manual updates and fostering real-time collaboration among engineering and manufacturing teams.

Procurement and Order Planning

Efficient procurement is essential for turning innovative designs into physical products. Xtend AI used OpenBOM to simplify and optimize procurement and order planning. By consolidating supplier information, tracking quantities, and generating purchase orders directly from the BOM, Xtend AI ensured a smooth transition from design to production, avoiding delays and oversights.

Cost Efficiency and Cloud Business Model

Xtend AI embraced OpenBOM’s cloud-based subscription model, which aligns with their agile and scalable approach to innovation. According to David Rubli, the SaaS and cloud model is preferable, especially for small and medium size businesses and he is advocating for that since his great experience with OpenBOM.

By avoiding costly upfront investments in traditional PLM tools and IT infrastructure, Xtend AI achieved significant cost savings while benefiting from continuous updates and enhancements. OpenBOM’s pay-as-you-go flexibility made it an ideal fit for their growing business, offering enterprise-grade capabilities without breaking the budget.

Conclusion

The story of Xtend AI showcases the transformative potential of OpenBOM for companies pushing the boundaries of technology. From managing complex data structures to optimizing procurement processes, OpenBOM proved to be an invaluable tool in helping Xtend AI achieve their vision of intelligent mobile robotics.

One important comment from David on top of everything – it is really fun to work with the OpenBOM Team. Check out the video to dive deeper into Xtend AI‘s journey with OpenBOM.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.