Engineers are very sophisticated people trained to solve very complex problems. They are actually proud of solving hard problems. And they use very sophisticated tools to solve these problems.

Engineers Fail in Simple Tasks

However, when it comes to Bill of Materials and data management, you’ll be surprised to hear that engineers are opting to use very rudimentary tools.

It always shocks me when engineers that just a minute ago discussed how to solve a problem in aerospace engineering, defense, or autonomous cars are working very hard to put together a nested BOM that will calculate the rollup of cost and quantity for components coming from super sophisticated design tools and send it to the procurement team.

In addition, they are also having a hard time communicating with the purchasing department the changes that need to be done because of the recent design change.

So, what is going on here? Why are engineers using such bad tools to solve the problem of BOM communication and collaboration? Why is it so difficult to coordinate changes made in multiple BOMs and plan how many parts they need to purchase and how many they have in stock?

At OpenBOM, we work with engineers that deal with BOMs, purchasing components as well as procurement teams on a daily basis. And guess what? We learned a couple of things along that way!

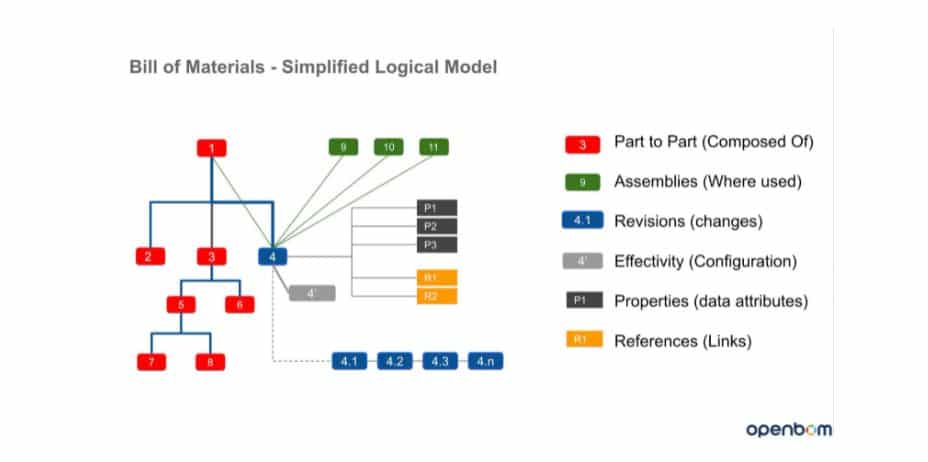

Product Structure And BOM Is Complex

BOM has a very simple structure – list of parts. When people think about it, things seem to be easy and simple. Just take a list of parts and put it together. Even the structure seems to be simple and logical. Here is a “simple” picture.

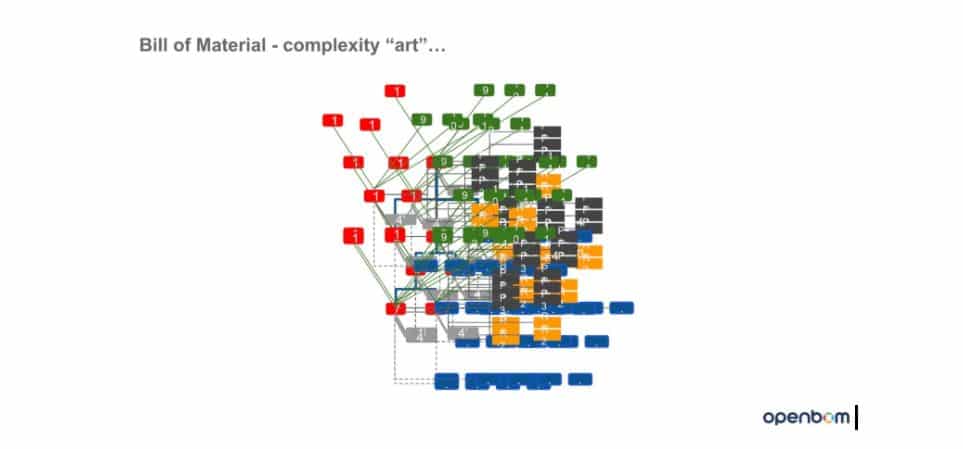

But when you start doing it, you find out that there are many lists, and they are used in different assemblies and the same parts need to have the same properties (Eg. Description, Cost, etc) in different places and then there are assemblies that are used in multiple places and they must be re-used with the same properties, but different quantities and then you need to calculate the quantities across multiple assemblies and you need to roll these quantities together and after all these things are done, you need to make a change…. Really?

So, the picture that looked very simple above is now becoming a messy spaghetti of data in multiple Excel sheets, to make matters worse, rarely do engineers know how to properly manage it. Think about the following picture to describe it.Change Is Hard

We all know from experience that change is something that is very hard. Bad habits are hard to change, engineers were trained to use spreadsheets.

Excel is the second-best software in the world in any domain and Bill of Materials Management is not an exclusion from this rule. I just need to describe a problem to an engineer and he/she will come to me back in 20 min with Excel that actually “solves” the problem. Pulling data in Excel is a natural engineering behavior and Spreadsheets became a native lingua franca in all organizations. Even if engineers want to change it, the organization will be pushing back.

Complex Solutions

There are many software systems that manage (or are supposed to manage) Bill of Materials. Unfortunately, all these tools were not focusing on how to make things easy. It is shocking, but most of these tools were designed actually to control the data and prevent the data from being accidentally changed. That created a complex behavior that slowed down engineers and made their work-life more difficult.

Try to load a Bill of Materials in an existing PDM/PLM/ERP tool and make a change, restructure, re-use, make calculations, etc.. The task can be so complex that many users of these systems are forced to export data to Excel, make a change and then load the data back. I’ve seen it so many times.

Old Tools Are NOT designed for collaboration

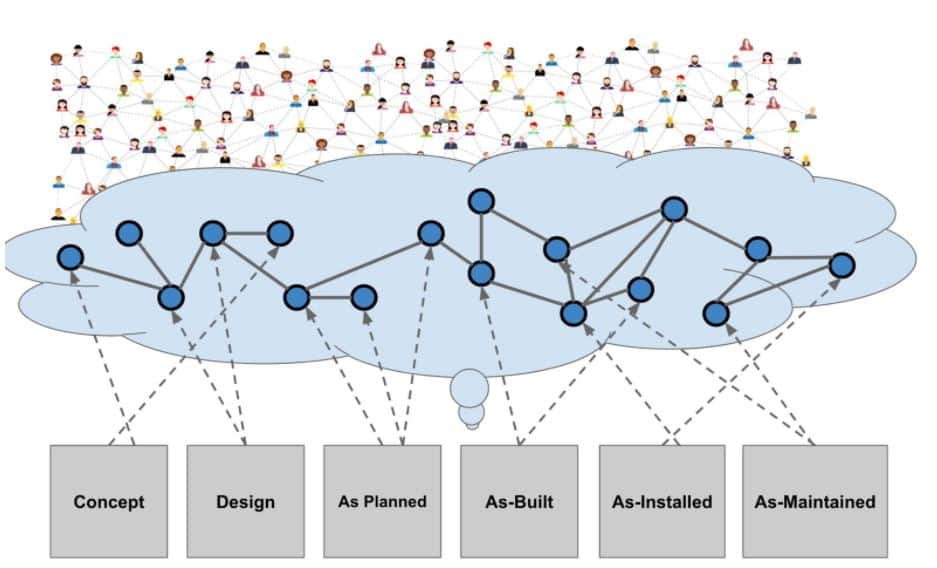

Another aspect of complexity is that all existing PDM/PLM/ERP tools were designed back 20 years ago with no intent to allow people to collaborate. Although all these enterprise systems were defined as “collaborative” aback in the 2000s, the meaning of collaborative tool was that they are “managing” data and controlling the access to the data.

The last two decades of web development created a completely new generation of tools and abilities to collaborate that most enterprise systems just don’t have. At the same time, engineers coming out of college actually demand this new form of collaboration.

How OpenBOM Solves The Problem of BOM Collaboration

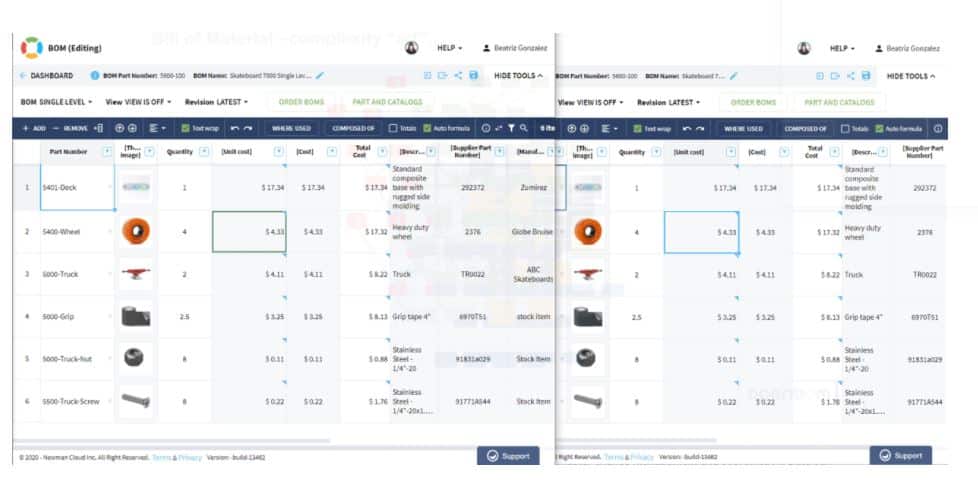

At OpenBOM, we designed the system from the ground up to be collaborative and to support easy data load, update, and manipulation that can be done simultaneously by the team. OpenBOM data management capabilities allow instant data sharing and collaboration with anyone located anywhere in the world just by using the browser. Think about Google Sheets with a huge amount of product structure and BOM steroids and you will get an idea of what OpenBOM is.

Check my video where I speak about OpenBOM collaboration and simultaneous editing.

Navigate to our training library to learn more about real-time collaboration.

Conclusion

BOM is not as simple as you might think. To manage product structure and Bill of Materials you need to have sophisticated tools. Unfortunately, most of the tools available today were developed 20 years ago and were focused on how to control data, which made most of them hard to allow people ease of change and collaboration.

At OpenBOM, we developed a new set of tools and technologies that can be used for flexible product structure editing and instant BOM collaboration.

Register for FREE to try OpenBOM today and discover how simple you can collaborate and stay on the same BOM with your team.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.