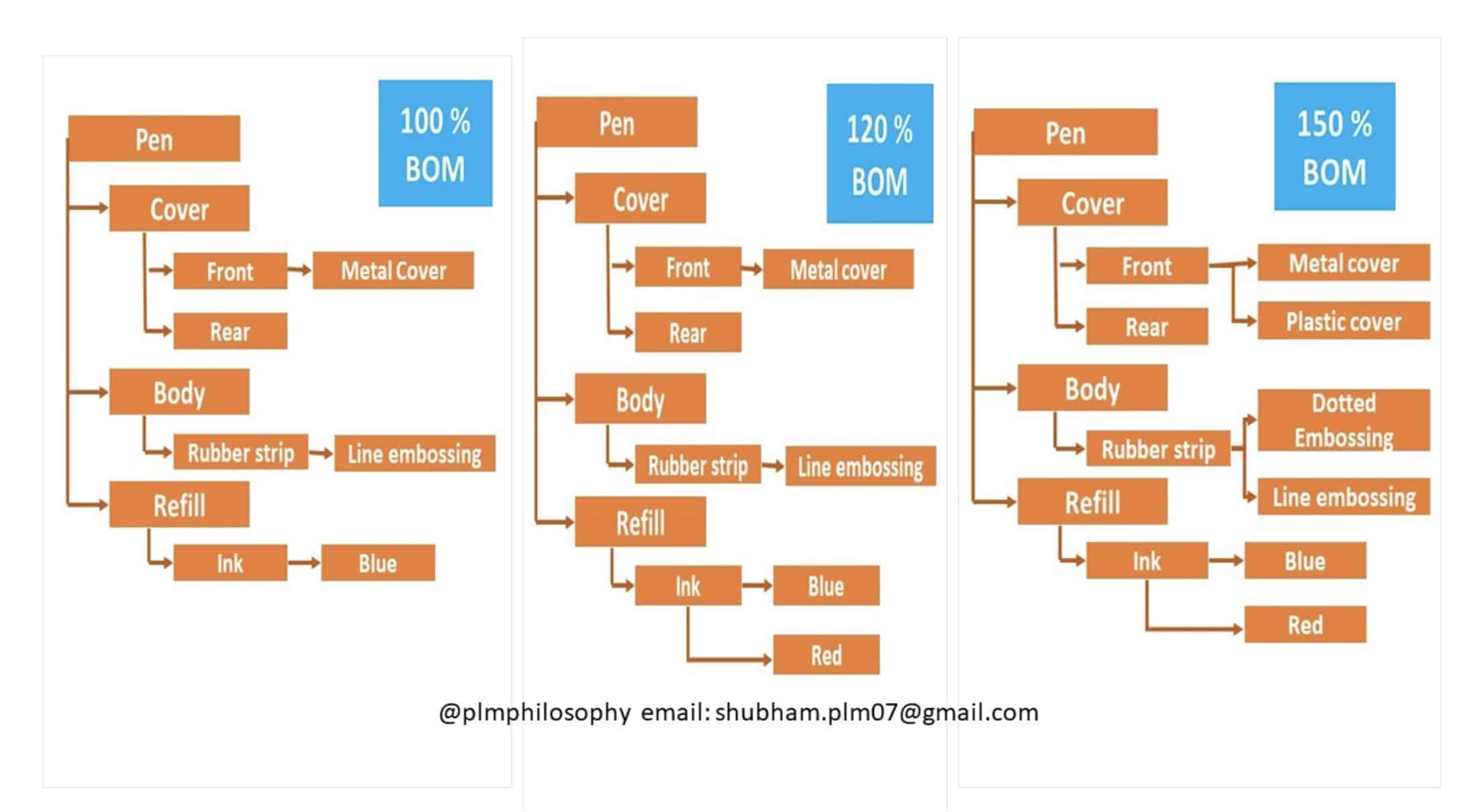

PLM Philosophy blog suggested an interesting article about 100%, 120% and 150% Bill of Materials. Check it out here What is mean by 100 %, 120 % and 150% BOM to get more details. Here are passage and the picture.

The BOM contains all alternative parts, full overlays of parts is known as 150 % BOM. As we see 120 % BOM is not suitable for manufacturing the final product, the 150 % BOM is also not suitable for making the final product. We have to convert it into 100 % BOM. The following figure shows 150% BOM. There are two options for the front cover(Metal and Plastic), two options for rubber strip(dotted and line) and two options for Ink color(blue and red). We have to select one option from each alternative to make a final product. In short, we have to convert it into 100% BOM.

The concept of “more than 100% BOM” is old and belongs to the ability to produce so-called configurable BOM with options. These options are actually presenting these 20% or 50% of overlaps in features included in the BOM. In such a way, to create a manufacturing bill of materials, you need “to resolve the BOM”.

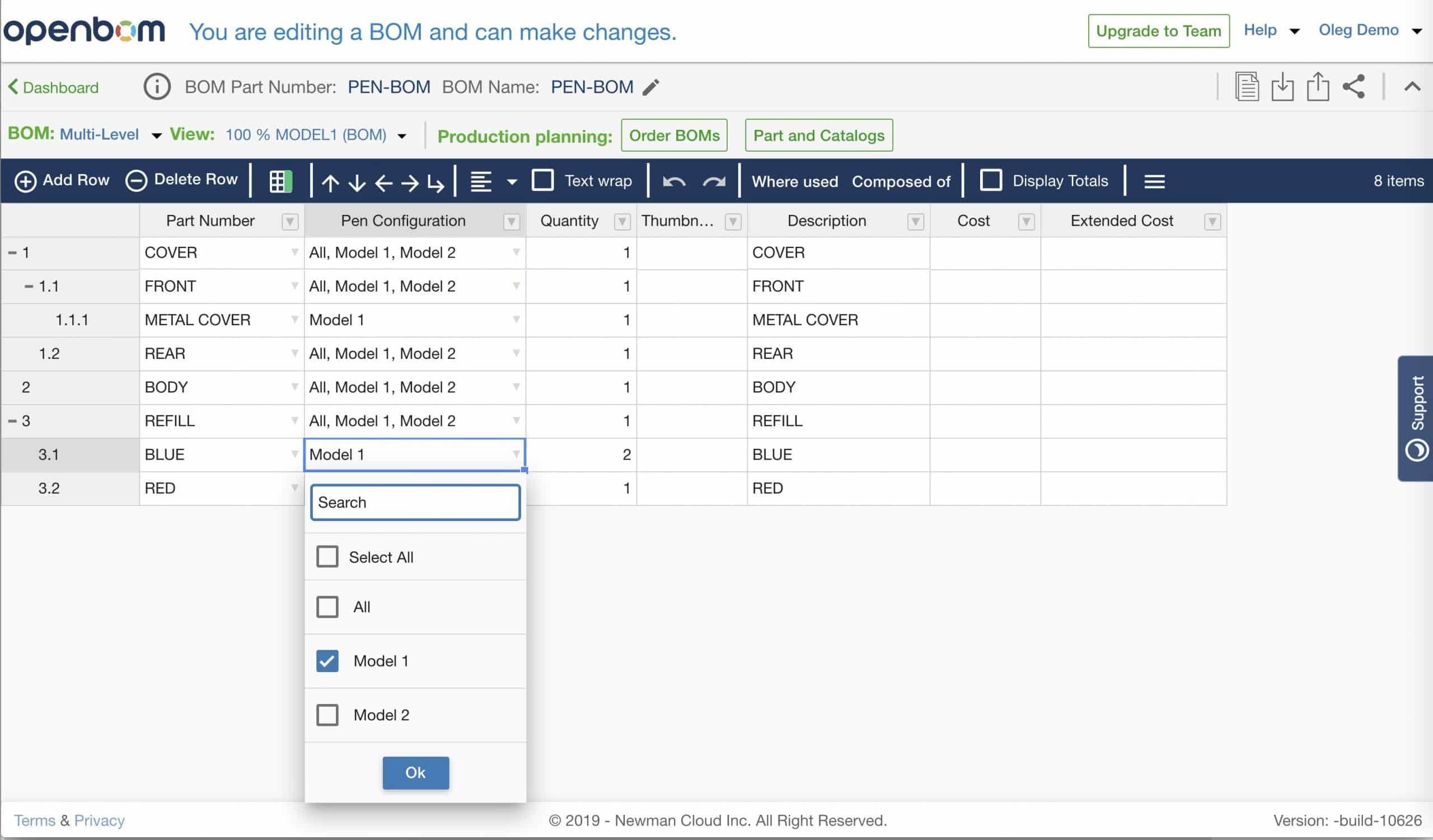

Today, I will show you how to create a model of options using OpenBOM. The way to do it in OpenBOM is to create a multi-select property and use it in OpenBOM user-defined view filters. Check this video.

Conclusion.

OpenBOM flexible data model with custom properties and the user-defined view is a powerful way to build a robust product model that can be used for product options and configurations. It won’t cover all configuration needs (it will come later), but gives you a mechanism to cover well-known 150% BOM options. Let me know what do you think and send your examples of Bills of Materials to test with OpenBOM.

Read OpenBOM customer reviews on G2 Crowd to learn what customers are saying about OpenBOM.

Try OpenBOM today by registering to FREE OpenBOM User Subscription.

Best, Oleg @ openbom dot com.

Let’s get to know each other better. If you live in the Greater Boston area, I invite you for a coffee together (coffee is on me). If not nearby, let’s have a virtual coffee session — I will figure out how to send you a real coffee.

Want to learn more about PLM? Check out my Beyond PLM blog and PLM Book website

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.