It’s no secret that the manufacturing sector is under pressure to reduce waste and improve efficiency. Organizations are using CAD software as a way to manage everything and combine it with the mess of homegrown solutions to manage design changes, Excel BOMs, and emails to communicate updates to production teams. But is it really the best option? In this blog post, I will continue the conversation I started in Part 1 and talk about the importance of structured design versions and product structure data, and change management.

Design and Product Structure Change Management

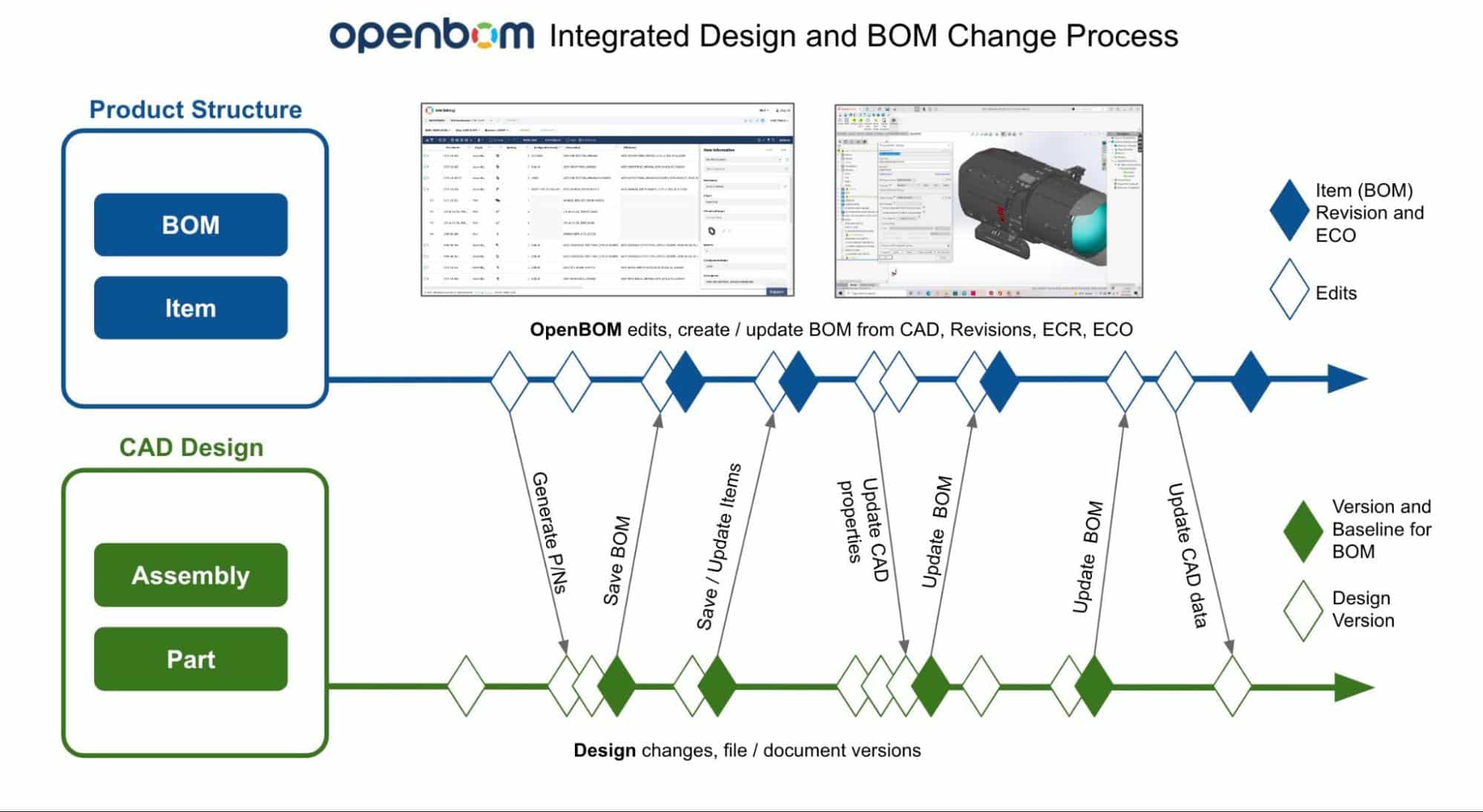

In the previous article, I discussed two fundamental processes that are happening in product development teams and manufacturing companies – (1) Design Lifecycle; (2) Product Lifecycle. The first is only focusing on the work that is done in the design process and focuses on how to control CAD versions and changes. the second lifecycle is a holistic process that is using product structure as a data foundation and includes all changes that are done with Item revisions including Item data, and Bill of Materials. The importance of holistically organized data including all this information is huge because it provides a single source of truth for all information in product lifecycle management. It is also very important to separate between changes that are happening in design (CAD) and overall product structure. These changes in CAD design are only focusing on a specific design (eg. mechanical, electronic, software, etc.) and later on are included in the overall integrated release process with the product structure (Items/BOM) data foundation.

OpenBOM Web Services To Support Design and Product Structure

OpenBOM provides two web services to support both the process of design versions (OpenBOM Drive Service) and BOM & Change management (BOM service) to manage all the data, files, history of files, item revisions, and Bill of Materials. Item and BOM management service automatically capture all changes and controls the revision process (either a simple revision comment or more complex change management, ECR/ECO functions)

OpenBOM Drive is a virtual drive that allows you to save and control changes for all engineering files (CAD files, specs, and other engineering documents – schemas, tech specs, etc.) Files placed on OpenBOM Drive can be instantly shared with all engineers working on the project or product design, versions are automatically captured and the history is preserved. The 3D viewer allows supporting access to design information without CAD systems. OpenBOM Drive is optimized for remote and distributed work and allows an entire virtual design and engineering team to work together, share all information and manage design versions.

OpenBOM Item and BOM management functions allow capturing information to build a Bill of Materials that includes everything you need to build a product. It is a multi-disciplinary product structure. OpenBOM flexible data model allows keeping all data attributes, capture revisions, and control change request/ order approvals based on roles defined in OpenBOM change order approvals workflow settings.

OpenBOM CAD Add-ins allow supporting “One-click BOM” process to capture data from CAD and synchronize the information between design and Items & Bill of Materials data structure.

Integrated Process Combining Both Lifecycles Together

OpenBOM services described above help to organize a fully integrated process to support the work of engineering and manufacturing teams together. In the diagram below, you can see both lifecycle streams (design, and product structure) go in parallel, and OpenBOM services manage data and help to keep information under control and in sync at the same time.

Conclusion

To support a complete product development process, you need to have the data management, change management, and process collaboration functions. These functions are essential to allow your organization to develop fast and to keep product cost and delivery under schedule. It cannot be achieved by the usage of homegrown tools, file folders, disintegrated PDMs, and sending Excels with BOMs and zip files to design partners and contract manufacturers. You need an integrated data and process management tool available to everyone involved in the process (not only to the engineering department) and allow to bring everyone on the same BOM and coordinate all changes. OpenBOM provides online services to support all the processes – starting from initial CAD design, and later moving to BOM creation, and engineering change.

REGISTER FOR FREE to check how OpenBOM can help you.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.