Earlier this week several customers asked me to clarify how OpenBOM can manage parent-child relationships. After answering on several questions, I decided to come with the blog post to share it with others as well.

So, first things first… OpenBOM has a mechanism to automatically capture and create parent-child relationships based on Part Numbers. It doesn’t require you to do something special. The point is OpenBOM will do it for you. It is enough just to use the same part number to create relationships between Assembly and Sub-assembly.

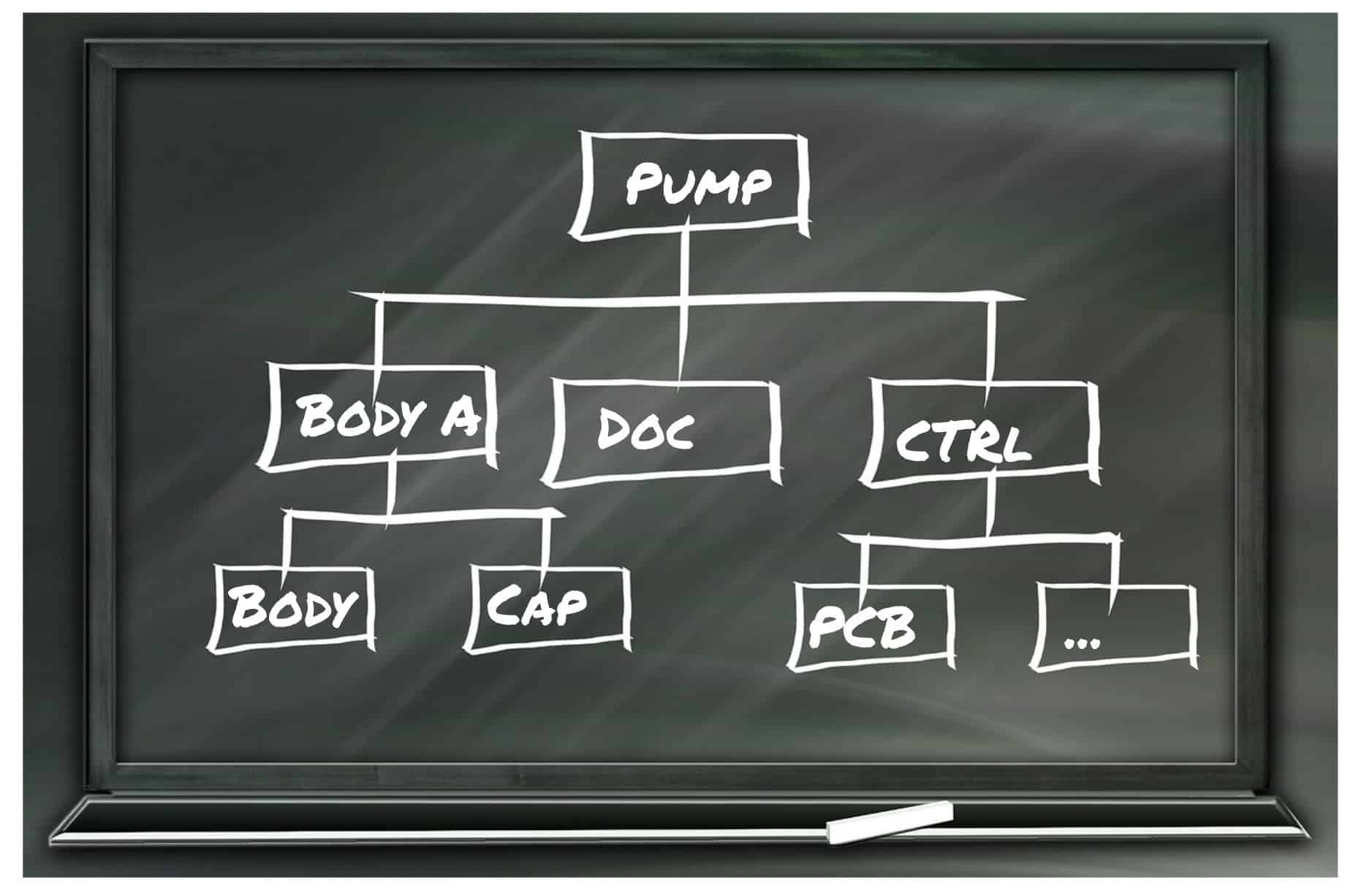

Check this picture and it will become clear to you.

Such a flexible data management option allows supporting multiple scenarios in the management of structures in OpenBOM. You can build structures top-down, bottom-up and not pay attention to what you create first – Upper-level assembly or sub-assembly.

The following video can give you an idea of what I’m talking about.

Another example in which I demonstrate how easy too change parent-child relationships and restructure Bill of Materials in OpenBOM (eg. Engineering Bill of Materials)

Conclusion

OpenBOM provides a robust and transparent parent-child relationship management systems. It allows you to keep flexible editing mechanisms by typing, selecting and changing of data. At the same time, it gives you a power of traceability in BOM structures.

Give me some feedback. What do you like and what needs to be improved.

Best, Oleg

PS. Let’s get to know each other better. If you live in the Greater Boston area, I invite you for a coffee together (coffee is on me). If not nearby, let’s have a virtual coffee session — I will figure out how to send you a real coffee.

Want to learn more about PLM? Check out my Beyond PLM blog and PLM Book website

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.