Engineering disciplines are hard and demand complex data structures and techniques to manage them. At OpenBOM, we don’t believe in the OOTB mantra (out of the box) and, instead, believe in building a flexible platform and solutions you can build and configure using this platform. Similar to how many engineers tweaked Excel spreadsheets, we believe that we can provide a unique experience of building solutions using flexible data modeling and deep integrations using OpenBOM.

I’m excited to introduce a new type of videos – Tech Tips that can help guide you through a very specific topic or scenario. We found video is a great way to communicate with customers in helping to solve specific technical issues.

Very often, we are getting requests with “how to” questions. We decided to start building a collection of tech tips and share them via a separate YouTube playlist – OpenBOM Tech Tips. This new YouTube playlist is designed to provide practical examples, best practices, and quick “how-to” guides for leveraging OpenBOM effectively in your projects.

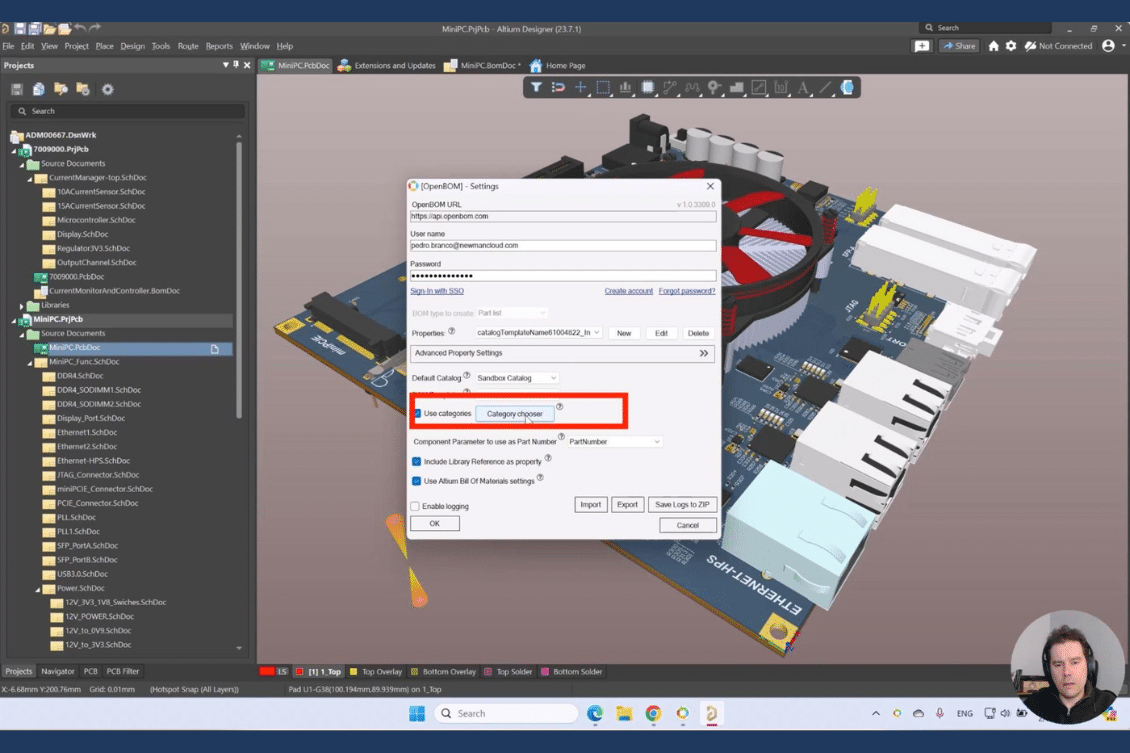

So, today, we are thrilled to introduce the first video in this playlist. Today, we’re diving into a specific tutorial focusing on utilizing Altium categories to streamline your BOM creation process.

Video Overview: Altium Designer Categories

In today’s video, OpenBOM customer success specialist Pedro Branco will guide you through the step-by-step process of creating a BOM with items saved in multiple OpenBOM catalogs using Altium categories. Here’s what you’ll learn:

- Setting up a catalog with a specific Part Number pattern.

- Configuring categories in Altium for seamless integration.

- Reserving Part Numbers using the Get Part Number function.

- Generating a BOM and securely storing the data.

Conclusion:

We’re incredibly excited about our new YouTube playlist, which will serve as a valuable resource for OpenBOM users to all our users. The same videos will also be shared on the OpenBOM Community Website – please register in our community.

Whether you’re new to OpenBOM or an experienced customer, our Tech Tips series aims to empower you with the knowledge and skills needed to optimize your BOM management workflow. Don’t forget to subscribe to the OpenBOM community and our YouTube channel to stay connected and up-to-date with the latest tips, tutorials, and industry insights. Here’s to streamlining your BOM processes with OpenBOM!

If you’re not using OpenBOM yet (it happens), REGISTER FOR FREE and check out how OpenBOM can help you today.

Best,

Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.