Efficiency is a killer in all manufacturing companies. Better, faster, cheaper. You probably heard it many times. Many manufacturing companies, especially small ones are experiencing significant difficulties in organizing their processes. The lack of IT resources and high levels of distribution are the key factors. Companies are working with contractors, designers, suppliers located everywhere and ending up with managing Bill of Materials (BOM) and Purchase Orders using Spreadsheets and Email. This is extremely inefficient and prone to mistakes that lead to low margins and delays.

Earlier this year we introduced OpenBOM Design to Purchase Solution. This function allows delivering an end-to-end design-to-purchasing process for engineering teams and medium-sized manufacturing companies. This functionality gives OpenBOM subscribers tools to plan Order BOMs, manage vendors and create purchase orders as a single integrated process fully integrated with design and engineering bill of materials process.

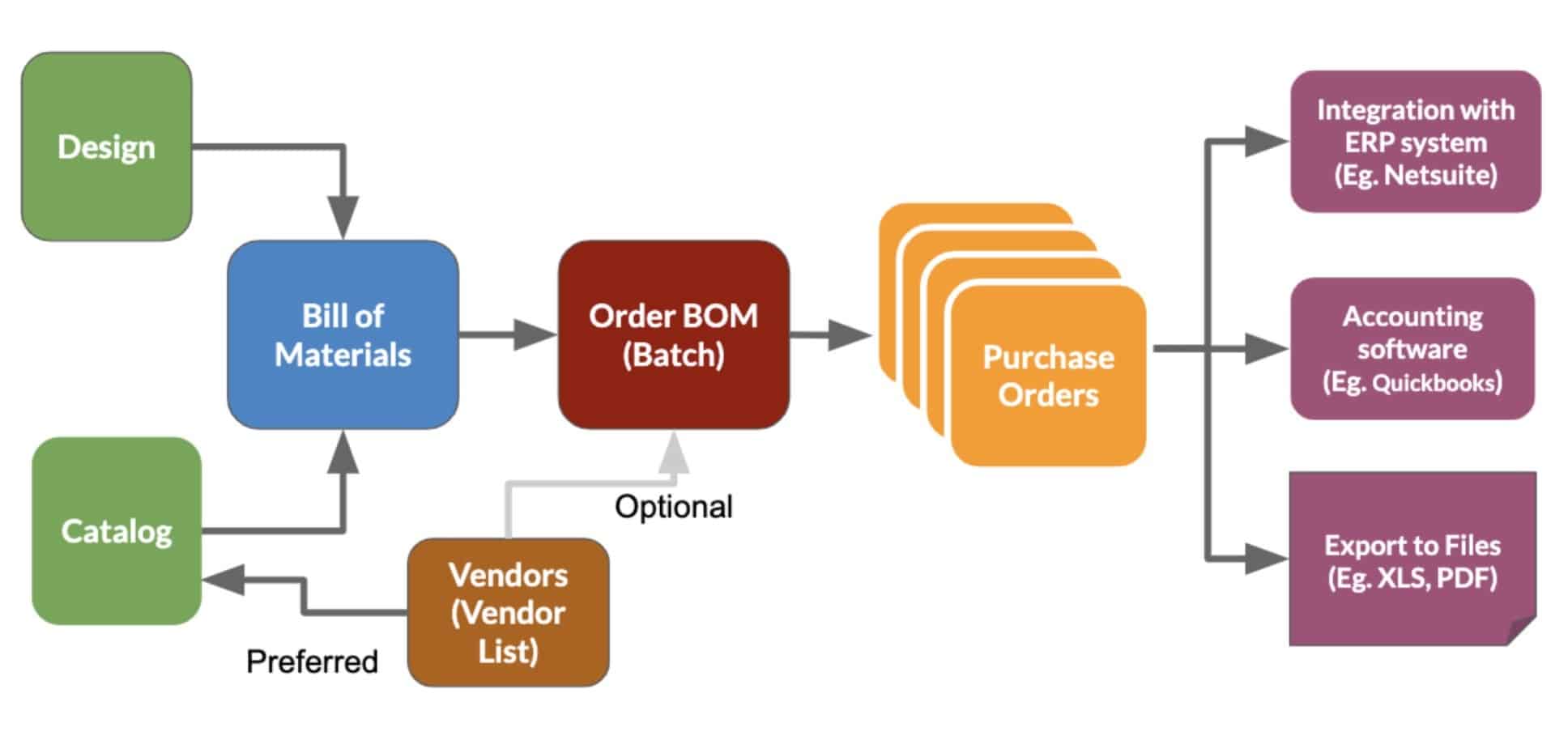

Take a look at a diagram I took from OpenBOM online documentation.

The innovative idea of this process is to provide a seamless and connected experience for engineers, manufacturing planners, and purchasing in small to medium manufacturing companies, prototyping teams, and manufacturing shops.

The key benefit of this solution is simplicity and efficiency. Combined with unique real-time collaboration provided by OpenBOM, it creates a unique solution tailored for small manufacturing companies. These companies are really struggling to find an efficient and affordable solution. OpenBOM gives a unique value proposition and functions.

The key enablements of this technology are multi-tenant data management, collaboration technologies and seamless integration with design systems (CAD systems like Solidworks, Autodesk Fusion360, Autodesk Inventor, Onshape, Solid Edge and others) developed by OpenBOM. Another important enabler is SaaS business model – OpenBOM is available via subscriptions globally.

Today I want to share two OpenBOM customer stories coming from two continents – Europe and the United States. What is common between these two stories is the way both companies are streamlining design to the purchasing process.

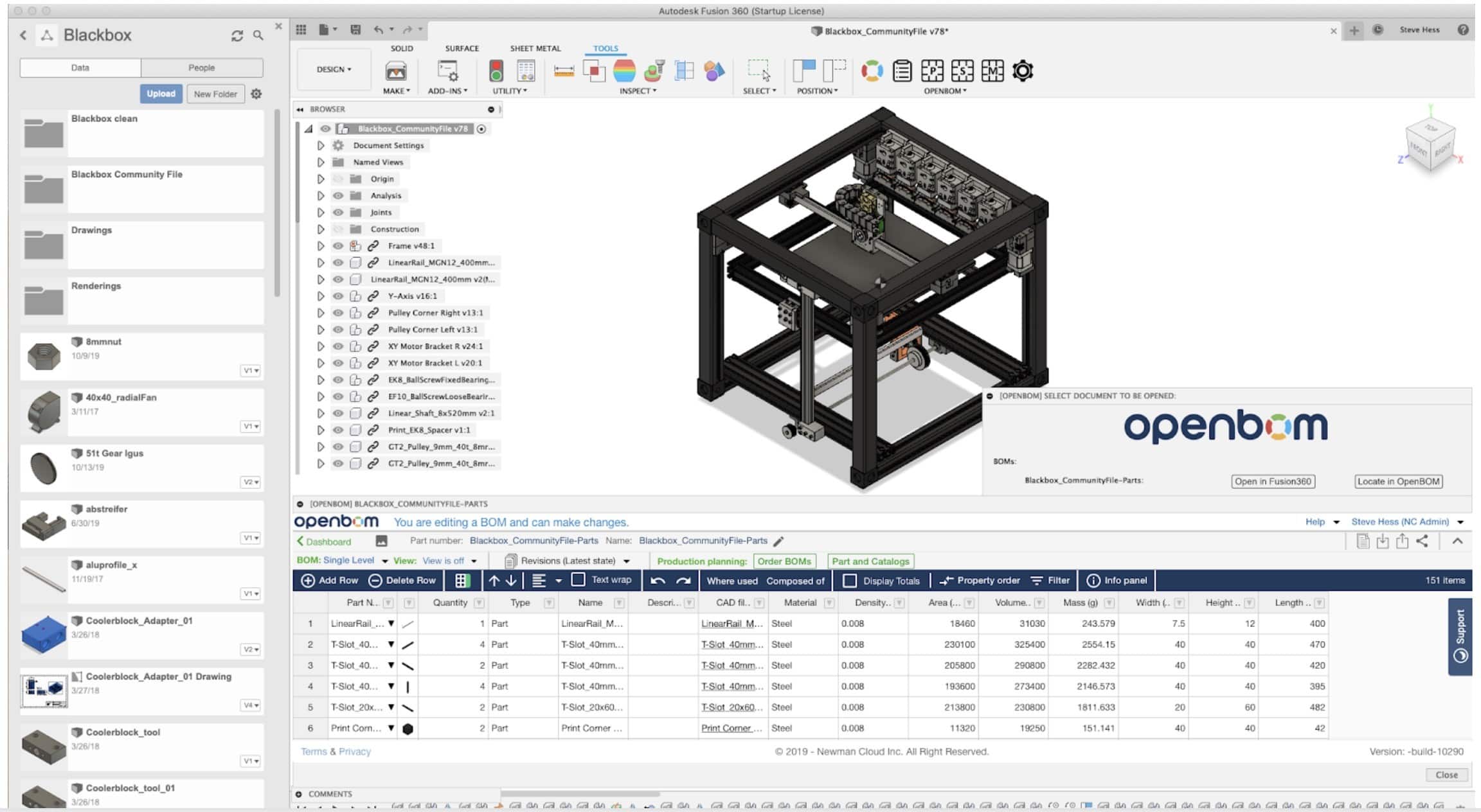

The first solution is Marc Schomann’s LayerShift project. You can learn more about the project visit Hackaday project Blackbox website sites and LayerShift website. Navigate here to read the story.

Here is my favorite passage:

Our distributed team used OpenBOM to capture product structure and assembly and part data from Autodesk Fusion 360 then create bills of material for purchasing the components we needed to build the printer,” Marc said. “The OpenBOM Fusion 360 integration made it easy to create and update BOMs and Part Catalogs and to identify and specify vendors as the design moved forward.”

A second company is X-naut. The company in Long Beach California developing iPad Cooling Cases. X-naut was founded by Darren Saravis in 2017 with its flagship product, iPad Cooling Case for iPads, was designed, tested and approved by the aviation market. This revolutionary product prevents iPads from overheating in extreme conditions.

You can read more about this story here. OpenBOM shines at X-Naut by automating the process of BOM creation from CAD (Solidworks) as well as by providing seamless support for purchasing processes

Here is my favorite passage:

The ease of use coupled with the production planning features of OpenBOM gives us the ERP features we need without all the ramp time, cost and maintenance of an on premise system” says X-naut CEO Darren Saravis. “OpenBOM’s ability to quickly bring together design and vendor information into a purchase order and manage quantity on hand helps us manage demand and inventory at our off-shore facilities”.

Conclusion

Simplicity is the ultimate sophistication. There are many PDM and ERP systems in the world, yet the most widely addressed market of small manufacturing companies aren’t covered. The companies are struggling with an outdated Excel driven purchasing process. OpenBOM solves the process to provide support with simplicity, elegance and the fastest possible ROI. If you want to learn more about OpenBOM, check the website, online documentation and our blog.

You can register to OpenBOM for FREE and check this out.

Best, Oleg @ openbom dot com.

Let’s get to know each other better. If you live in the Greater Boston area, I invite you for a coffee together (coffee is on me). If not nearby, let’s have a virtual coffee session — I will figure out how to send you a real coffee.

Want to learn more about PLM? Check out my Beyond PLM blog and PLM Book website

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.