The manufacturing industry is changing. A long time ago, manufacturing shops were big and slow. Over the past 15-20 years, the manufacturing industry has discovered contract manufacturing, global market, and many other things that can make manufacturing distributed. You might think that manufacturing companies are all set…

The next wave of manufacturing is coming — Manufacturing DevOps. Last week, I was listening to Eric Anderson of ScaleVC at COFES 2019.

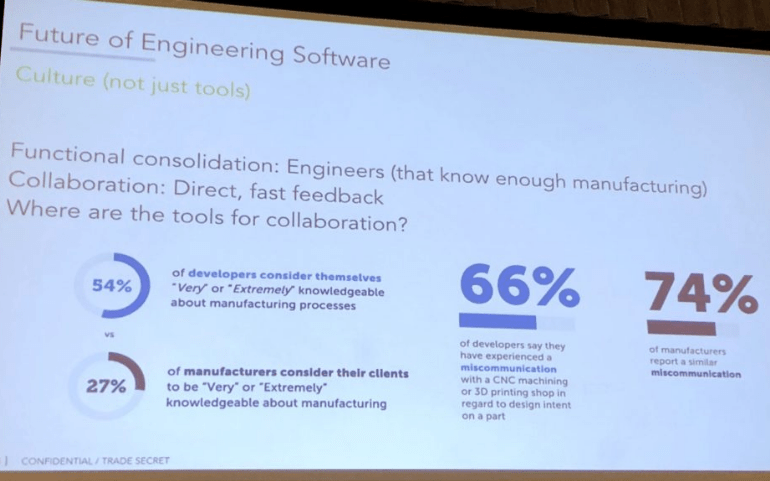

According to Eric, there is a big need to bring new collaborative software to manufacturing. You can ask why so? Collaboration was a topic for CAD and PLM software for a long time. Not really… A different type of collaboration needed. Something we’ve seen before only in software companies — continues development and DevOps. This is the goal.

It will allow manufacturing companies to perform faster, but more importantly and intelligently.

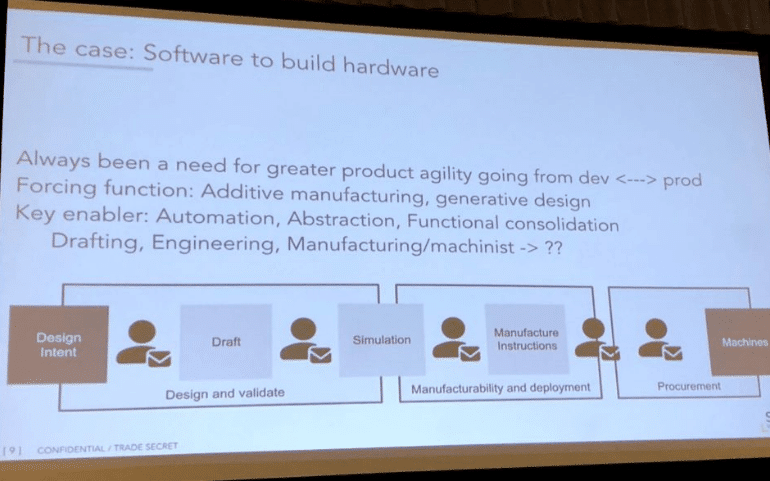

Here is a typical manufacturing flow:

Collaboration is a key in the future of Engineering Software.

These messages are resonating with the strategy we have at OpenBOM. One of the key elements of OpenBOM is to allow people collaborating fast. You can say — everybody is collaborating. Look at Engineering and Manufacturing software 10-15 years ago and you will see a lot of “collaborative” software. What is so different in OpenBOM?

The thing in collaboration is to make it easy and global. You can find many manufacturing companies using engineering data management software. Are they collaborating? Yes, of course. But they have spent lots of internal resources to make it happen. OpenBOM does it differently in 2 ways:

1. Seamless and real-time

The core element of OpenBOM — collaborative grid, allows you to instantly get information and make it available between people located in different places at the same time. We call it “to stay on the same BOM” but, of course, it goes beyond BOM. OpenBOM provides contextual and gives the feeling of presence (similar Google Spreadsheets does).

2. Global and accessing multiple teams and companies

Business is changing fast. Companies are making decisions to work with other people and companies, and they have no idea how to organize it and get prepared. OpenBOM supports multi-team, in/out company collaboration. The information access is secured but you can always add a person or team to collaborate instantly.

Check this short video demo about OpenBOM real-time collaboration:

More advanced collaboration scenarios can be realized with OpenBOM Team views:

Conclusion

The demand for better communication and collaboration is high. In the fast and growing business environment, the ability to communicate is priceless. Providing efficient and affordable communication tool can help manufacturing companies deliver faster, with high quality and less cost.

Subscribe to OpenBOM today to experience a new way to collaborate in engineering and manufacturing. Check out OpenBOM subscriptions.

Best, Oleg

P.S. Let’s get to know each other better. If you live in the Greater Boston area, I invite you for a coffee together (coffee is on me). If not nearby, let’s have a virtual coffee session — I will figure out how to send you a real coffee.

Want to learn more about PLM? Check out my Beyond PLM blog and PLM Book website.

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.

The need for collaborative software in manufacturing is crucial for accelerating productivity. DevOps practices can transform manufacturing by enabling seamless, real-time collaboration across global teams. OpenBOM’s approach, with its easy-to-use, instant information sharing, is a game-changer, allowing companies to stay agile and make smarter, faster decisions in a distributed environment.