Product Structure of the Bill of Materials is the lifeblood of product development and manufacturing. Think about every product that companies are designing, manufacturing and using. The information about parts, how many of them, who manufacture them and where companies purchased them is a foundation of the company product development process. Information about what is used, purchased price, vendors company are working with, maintenance data, regulation, and certification… and many other prices of information are siloed in multiple Excel files and legacy databases.

So, far I didn’t say anything you haven’t heard before. For ages of data management systems such as PDM and PLM were sold with the idea to organize a single version of the truth. Until now, it is one of the strongest value propositions embedded in every PLM sales process.

A single version of the truth is still a very good thing when you sell the PLM system. In most of these sales situations, the value is improved data organization, performance, and efficiency. These are still core elements of the PLM sales process.

But, the new things are coming. Forbes article – Top Artificial Intelligence (AI) Predictions For 2020 From IDC and Forrester gives you a glimpse of what is coming next in the space of decision support and importance of AI and data science in the future of intelligent systems.

Here are few interesting data points:

According to Forrester’s various surveys, 53% of global data and analytics decision-makers say they have implemented, are in the process of implementing, or are expanding or upgrading their implementation of some form of artificial intelligence.

IDC predicts that by 2022, 75% of enterprises will embed intelligent automation into technology and process development, using AI-based software to discover operational and experiential insights to guide innovation.

How this (AI) innovation is intertwined with BOM (Bill of Materials) and related pieces of information such as sourcing, price, vendors and others? Here is the thing – when it comes to AI and data science, the quality and sources of information are one of the most important factors. You need to get good information to form predictions and drive intelligence. And product development, sourcing and manufacturing intelligence roots are in the Bill of Materials data.

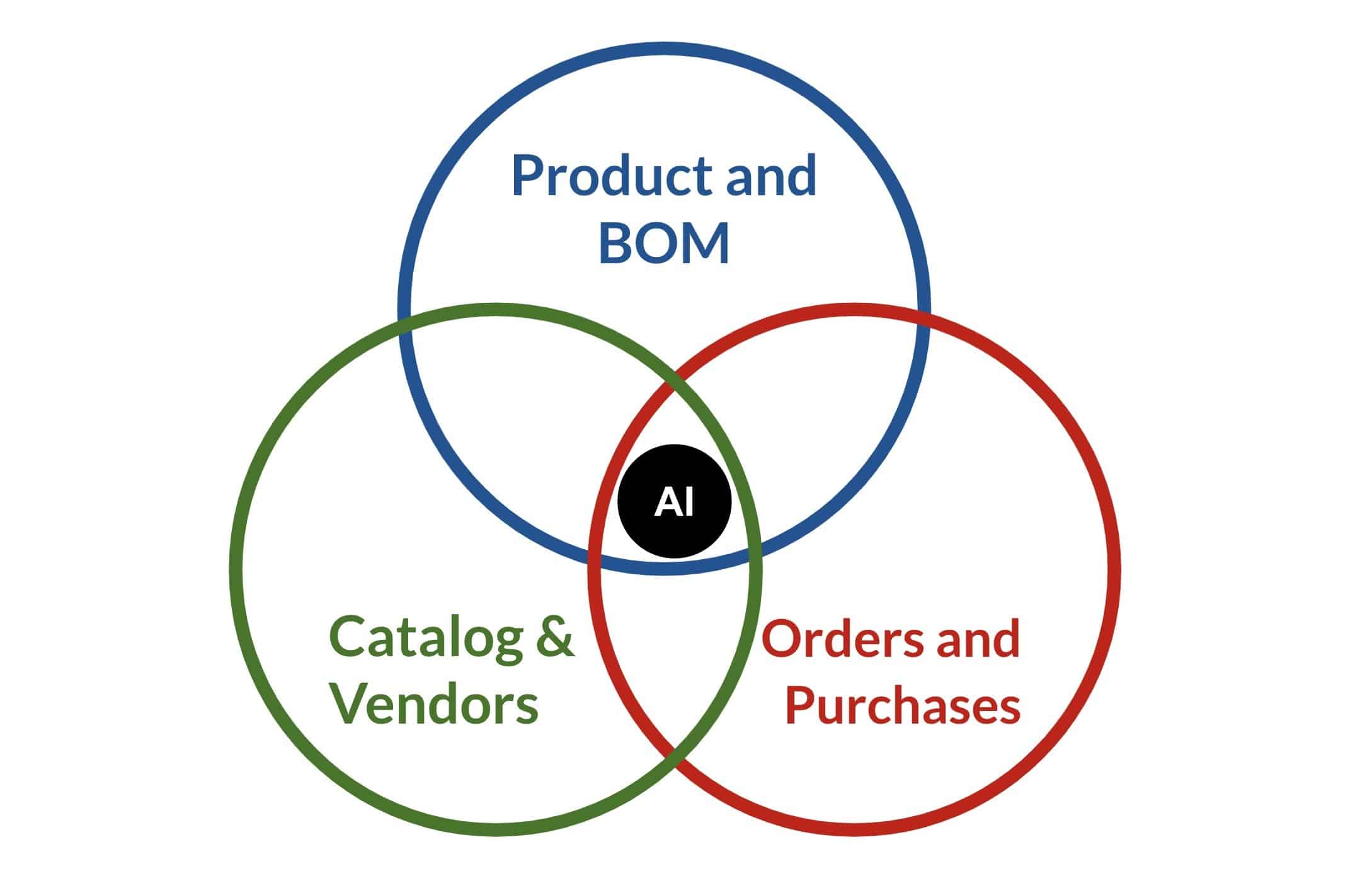

The main triangle of product development, source, and manufacturing intelligence are in a combination of these three data sources: (1) Product, (2) Vendors, and (3) Purchases. The first gives you all the information about the product. The second gives you intelligence about who is providing services and parts and the third is a source of historical record about who was buying what and when. Combine them together and you will get intelligence of future product development and manufacturing.

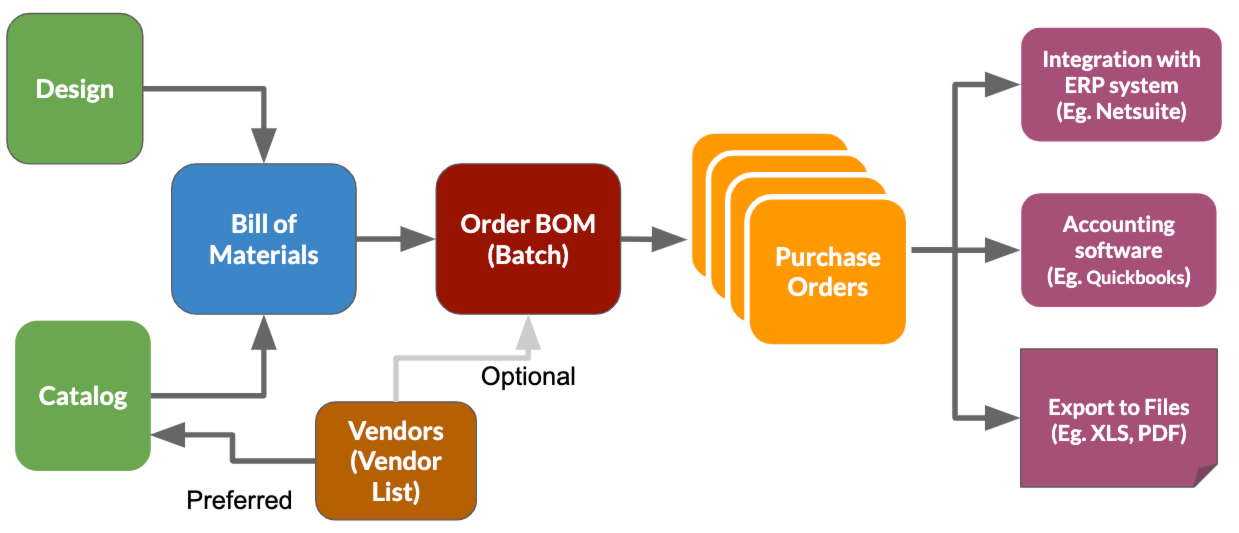

OpenBOM design to purchase workflow provides a data management foundation for every company to connect these three pieces of information.

When a company using OpenBOM, these three silos of the information – Bill of Materials, Vendors and Purchase Orders are intertwined and connected together. It gives you a foundation for product decision making intelligence.

Conclusion.

AI will play a significant role in the future of complex product development, manufacturing and sourcing decisions. Bill of Materials and connected information will play a huge role in the way the data foundation for future manufacturing AI will be created.

At OpenBOM we believe in the power of the future intelligence and decision management system for product development, sourcing, and manufacturing.

Try OpenBOM today by registering to FREE OpenBOM User Subscription.

Best, Oleg @ openbom dot com.

Let’s get to know each other better. If you live in the Greater Boston area, I invite you for a coffee together (coffee is on me). If not nearby, let’s have a virtual coffee session — I will figure out how to send you a real coffee.

Want to learn more about PLM? Check out my Beyond PLM blog and PLM Book website

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.