Register for 14-days free trial

I’m going to walk you through the process of escaping from messy Excels and Spreadsheets to well organized BOM. Please scroll the page, read the stories from our customers watch our videos and examples. Click on on the button Click On The “Buy OpenBOM To Join 1000+ Engineers That Already Escaped Spreadsheets…” to start working with OpenBOM and change the way manage Bill of Materials, making rollup cost calculation, sharing data with your team and working with contractors and suppliers.

What Customers Are Saying About OpenBOM?

Read stories from our customers worldwide using OpenBOM to change the way they manage Bill of Materials and collaborate with their contractors and suppliers.

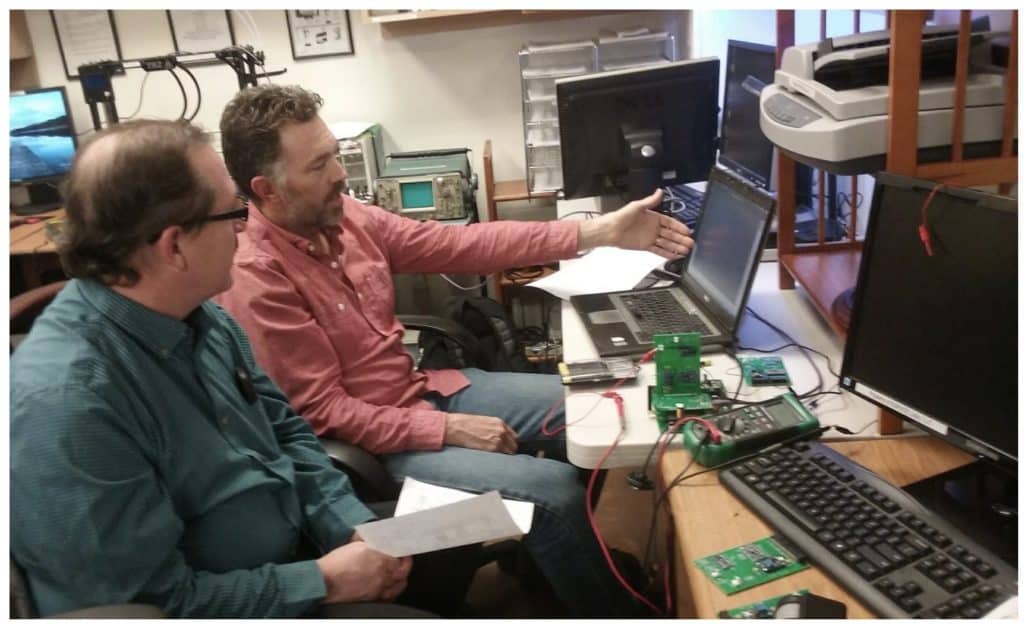

1. E::SPACE Labs

The company moved from messy data organization and data spread over multiple places coming from Autodesk Fusion 360 and Autodesk Eagle to a structured information using OpenBOM. E::SPACE: OpenBOM gives us a structure and discipline to keep track of our important designs.

David Robson one of the founders of E::SPACE Labs says:

“The multi-disciplinary aspect of OpenBOM and the only one of it’s kind integrations to Autodesk Eagle and Autodesk Fusion 360 save us valuable time and greatly improve accuracy and reliability”

Join 1000+ engineers using OpenBOM today…

2. EA Manufacturing

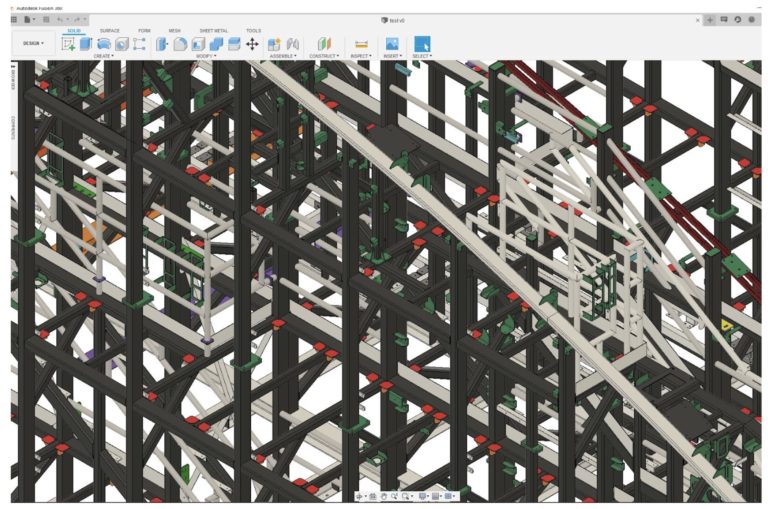

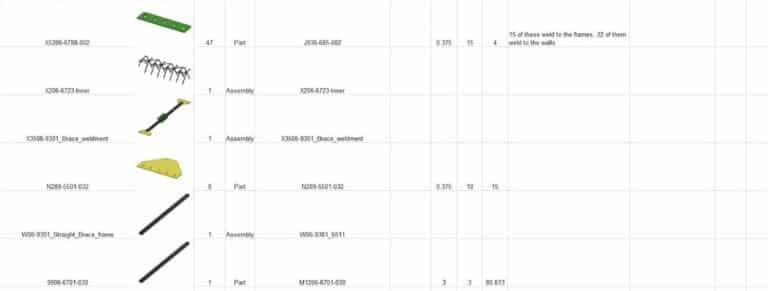

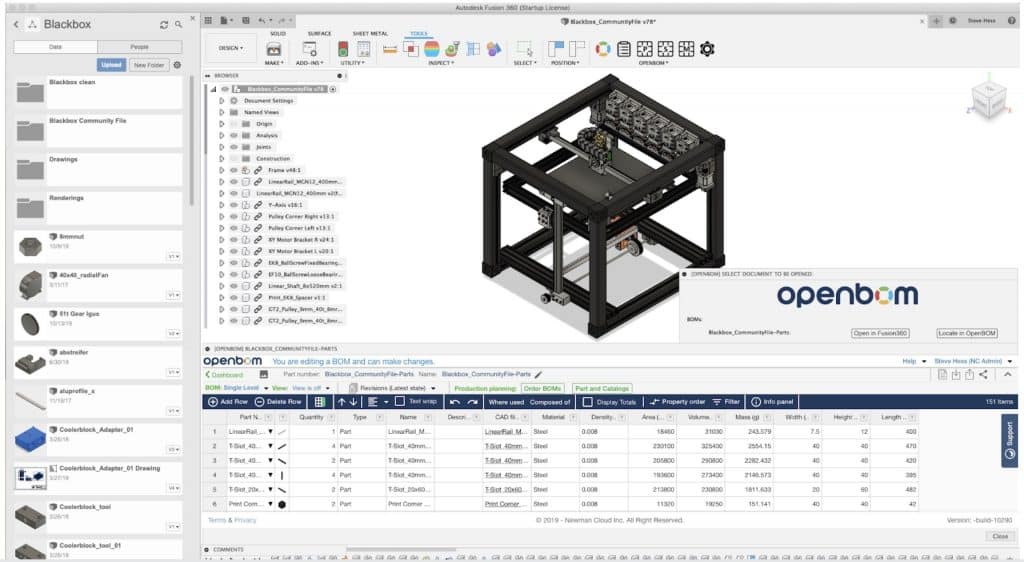

EA Manufacturing relies on OpenBOM and Autodesk Fusion 360 to solve a major manufacturing issue for a leading provider of massive outdoor structures. Brian Kraut and EA Manufacturing of Florida, USA, rely on OpenBOM and Autodesk Fusion 360 to solve a major manufacturing issue for a leading provider of massive outdoor structures. OpenBOM and Autodesk Fusion 360 collaborate to solve leading outdoor structure designers’ major problems.

Brian was contacted by a new client in big trouble. They had a very large investment of time and money into a design (by another design firm) which was ready to go to manufacturing. But the client could not go to the manufacturing phase because they didn’t know how many of each component they needed. The client asked the original designer to provide the detailed Bill of Materials but they could not. Keep in mind this is a complex design, with mirrored parts, left and right parts, assembly variants, configured lengths, etc.

“My client was stuck and needed someone to take their design data and turn it into a manufacturing Bill of Materials”, says Brian. This is where EA Manufacturing and OpenBOM stepped in.

The client sent Brian a STEP file over 1.2Gb! Brian uploaded the file(s) into Autodesk Fusion 360 and began to organize the design. He discovered the design had over 24K individual parts, which OpenBOM and Autodesk Fusion 360 handled nicely.

Brian used the OpenBOM for Autodesk Fusion 360 add-in to create a Multi-Level BOM of the entire design. However, it was OpenBOMs Flatten function which really provided the power Brian (and the client) needed. Brian used Flatten to identify ALL the individual parts and assemblies AND THEIR QUANTITIES (regardless of their location in the product structure) so they could take the design of the steel manufacturer and have the correct number of parts made!

“I love how the thumbnail images displayed on the screen and in the exports. The material types, thicknesses and other part properties also came through into the BOM literally saving me hours of time specifying material properties for each part” says Brian. “Having Multi-Level product structure is great!” he added.

Brian’s client was so happy they also purchased an OpenBOM subscription and loved the collaboration aspect eliminating the need to send BOM data back and forth through emails. Brian says “My client loved having one single source of truth for their BOM mastered in OpenBOM.”

Join 1000+ engineers using OpenBOM today…

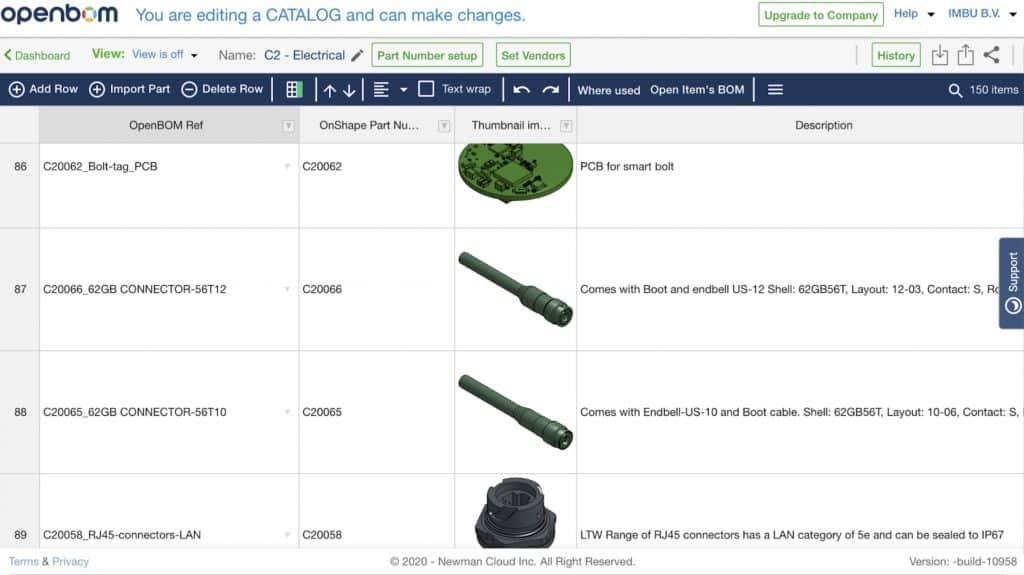

3. IMBU

In another example IMBU moved from complex and not automated environment to a simple way to organize data using OpeBOM. IMBU is using Onshape and OpenBOM integrates well into Onshape environment.

“The OpenBOM / Onshape suite of tools works extremely well for us. OpenBOM creates both Catalog inventories and Multi-Level BOMs directly from our Onshape models”. Says Byron van Gool IMBU Mechanical Engineering Manager. “We rely on the ability of OpenBOM to integrate tightly with our Onshape design structure and create a Multi-Level BOM. We then connect our OpenBOM item master catalog to that BOM to enable reuse of our extensive items catalog”

IMBU also uses OpenBOMs unique formula feature to perform multi-level calculations for pricing. “The ability to rollup the cost of sub-assemblies and items in a BOM to the top level saves us hours and hours of manual calculations”, says Gert.

Similar to our own IMBU Web Suite of monitoring tools, OpenBOM runs entirely with a web browser. “We like the simplicity and portability of that” says Gert. “It just works!”

Join 1000+ engineers using OpenBOM today…

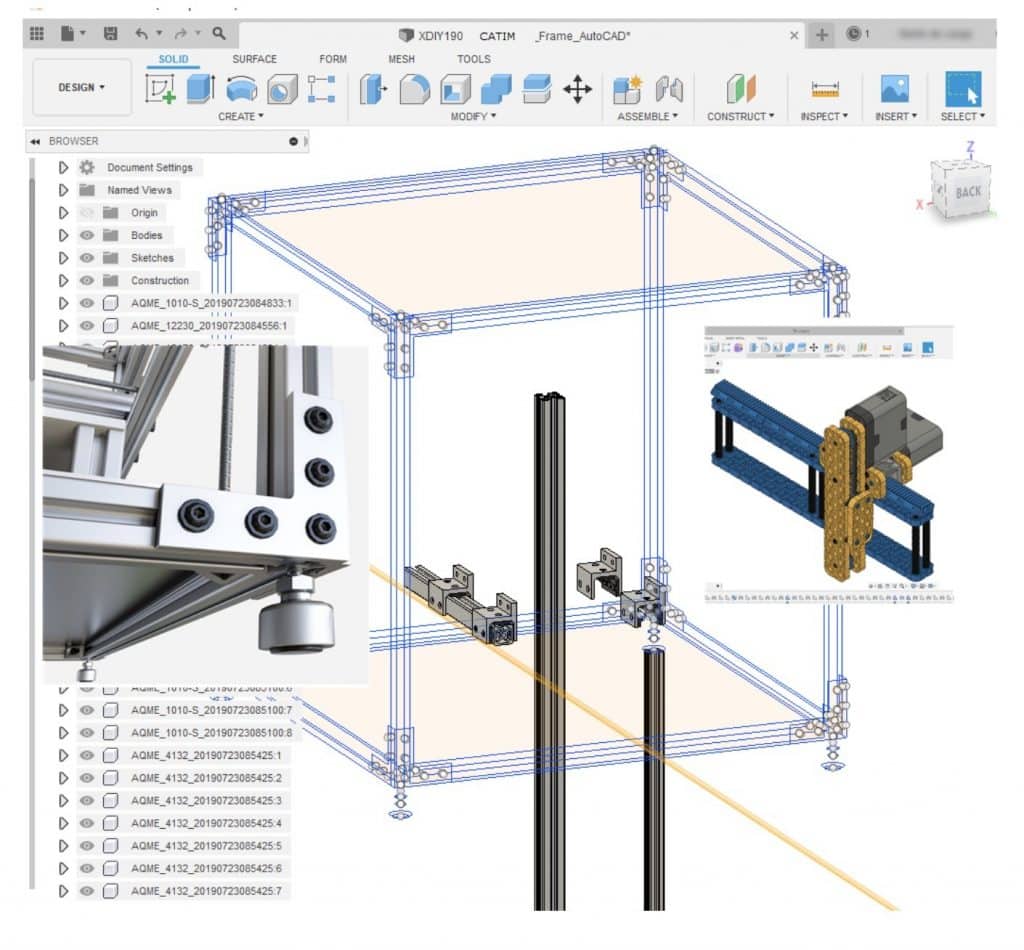

4. CATIM

In another example, CATIM, electric equipment manufacturer from Australia using OpenBOM to move from manual process to automated environment managing BOMs and related information literally saving hundreds hours a year using OpenBOM.

Here is what CATIM Design Manager says about OpenBOM usage:

CATIM discovered OpenBOM out of simple necessity. “We needed some way to make a BOM from Autodesk’s Fusion 360,” says their Design Manager. “I went to my keyboard and quickly discovered OpenBOM. We gave it a try and are now saving literally hundreds of hours a year with OpenBOM”.

Join 1000+ engineers using OpenBOM today…

5. X-Naut

Long Beach, California based X-Naut making the entire X-naut team from design to supply line to manufacturing rely on OpenBOM and moving away from not organized data in Excels.

X-Naut is using Solidworks and creates Catalogs, BOMs necessarily to make their products directly from Solidworks using OpenBOM add-in.

As demand for the unique products quickly grew X-naut found themselves hustling to managing the components and supply lines necessary to meet the expanding demand. X-naut relies on OpenBOM to quickly capture the product structure form the 3D CAD designs and create the Items, Catalogs and Bills of materials necessary to produce their products.

“The ease of use coupled with the production planning features of OpenBOM give us the ERP features we need without all the ramp time, cost and maintenance of an on premise system” says X-naut CEO Darren Saravis. “OpenBOM’s ability to quickly bring together design and vendor information into a purchase order and manage quantity on hand helps us manage demand and inventory at our off-shore facilities”.

Join 1000+ engineers using OpenBOM today…

6. LayerShift Project

Marc Schömann and the LayerShift project was manually capturing BOM and related information for his 3D printer design using Autodesk Fusion 360. He was struggling with non organized data and was looking to clean the messy information into a manageable environment. OpenBOM gives him this opportunity and data now is completely under control allowing him to manage BOMs and coordinate purchases.

“Our distributed team used OpenBOM to capture product structure and assembly and part data from Autodesk Fusion 360 then create bills of material for purchasing the components we needed to build the printer,” Marc said. “The OpenBOM Fusion 360 integration made it easy to create and update BOMs and Part Catalogs and to identify and specify vendors as the design moved forward.”

Join 1000+ engineers using OpenBOM today…

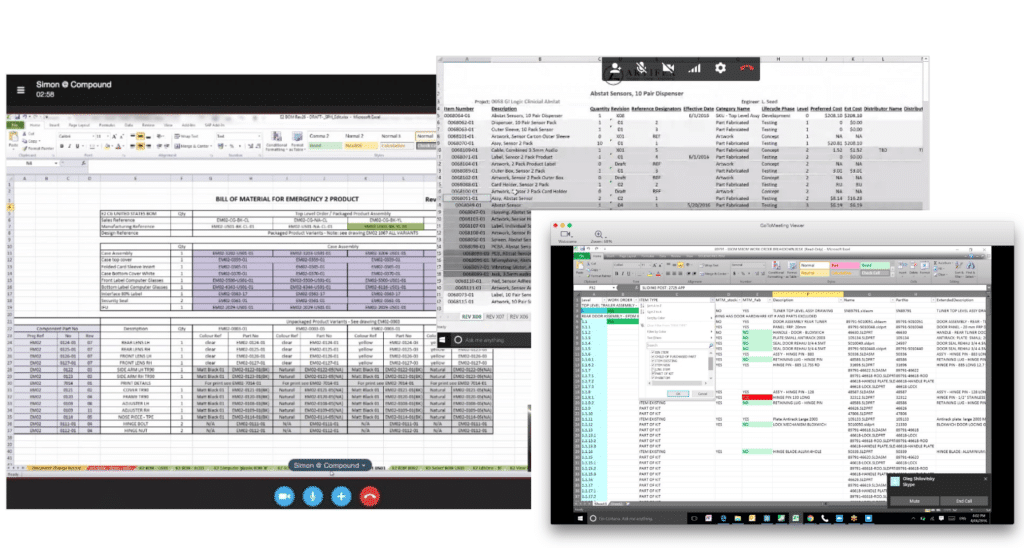

You tried Excel or Google Spreadsheet and it didn’t work…

You’re an engineer in a manufacturing company who is working on design, engineering and production tasks individually or as part of the team. While you’re enjoying building an innovative products and finding unique engineering solution, you’re struggling with the need to manage Excel files with bill of materials, accounting for parts, quantities, rollup cost, mass and many other management tasks, You continuously failing to communicate efficiently with other team members and department responsible for production and purchasing. You’re stressed by the need to manually export data from CAD system counting parts, making updates.

You have tried different Excel and spreadsheet templates. You tried Google spreadsheet. They are simple to start with, but they are getting complex within time. Also, spreadsheets are absolutely not fit if you need to manage nested structures, rollup quantities and having a single data storage for parts – data is easy becoming redundant and everything is messed up. Also, sharing data with somebody else and updating it at the same time, is insanely complex. Data is often lost or not updated data is shared with the people that need to make purchases.

SaaS is taking over the cloud computing market. Gartner predicts that the service-based cloud application industry will be worth $143.7 billion by 2022—a level of growth that will shape SaaS trends in 2020. As much as 80% of organizations are predicted to migrate toward the cloud by 2025. In 2018, public cloud adoption grew to 92%.According to Tech-Clarity research, cloud /SaaS software helps companies to achieve a greater value on their path to improving innovation and engineering performance. Implementing engineering and manufacturing software in the cloud (SaaS) offers value across multiple dimensions – operation, business, engineering advantage, strategic.

Staying with old fashion Excel spreadsheet, you can expose yourself to potential mistakes, production delays, excessive cost and missing production targets. Somebody else will come to your place and will eat your lunch by developing products faster and with lower cost.

By deferring to existing non- SaaS PDM and database solutions, you put your manufacturing and business goals at risk, exposing to significant IT and operational cost. . By continue to manage data using Excel and variation of spreadsheets, you’re exposed to painful mistakes such as wrong orders and delays.

But you can escape Excel…

Here is the truth: You can easily escape messy Excels and stop doing manual Bill of Materials calculations. However, here is the thing – most software products out there are not equipped with a unique set of functions and capabilities as OpenBOM.

OpenBOM gives you a unique way to change what you do with the Bill of Materials and other related tasks in less than fifteen minutes. It is because of unique technologies and CAD integrations we developed at OpenBOM.

Join 1000+ engineers using OpenBOM today…

OpenBOM Story

Before we get into the steps and how-tos, here is a quick background on our company.

For those who don’t know me, my name is Oleg Shilovitsky and I spent 20+ years developing PDM and PLM software for the industry, working for companies like Autodesk and Dassault System. I also co-founded my previous startup, which was sold to Autodesk in 2012.

I’m also writing a daily blog – Beyond PLM (beyondplm.com) for the last 12 years where I’m sharing my knowledge and experience about engineering and manufacturing software. Before starting OpenBOM, I worked for Autodesk where he was responsible for data management and PLM system development.

OpenBOM was founded in 2015. Our founders have a proven record of working for established companies in the technology domains such as Dassault Systems, Autodesk, HP, EMC, and others.

I had huge exposure to the problems of PDM, PLM, and ERP software from my previous work experience. After experiencing all problems with using Excel as well as the challenges of using expensive PLM and ERP software, I started OpenBOM with a clear vision to help change PLM and BOM management with a new technology and platform – OpenBOM.

I’ve seen a huge opportunity to change PLM software by using modern cloud/SaaS technologies and developing a unique product that can be available online to all manufacturing companies.

Integration with engineering and manufacturing software is strategically very important for OpenBOM. Therefore, from the very first day, we established a partnership with CAD, PLM and ERP companies helping us to built best integrations between CAD/PLM/ERP systems and OpenBOM.

OpenBOM is available from 2016 and since that time we’re serving tens of thousand manufacturing companies and engineering teams globally.

Join 1000+ engineers using OpenBOM today…

Think of OpenBOM as a Google Spreadsheet with a huge portion of Bill of Materials, PLM and ERP steroids

I was managing product development teams and found how my work was getting easier if my teams had a shared Google spreadsheet with the information about what we do -projects, action plans, etc. Google Sheets can be easily shared and update information in real-time. It was my aha moment how to start OpenBOM.

Here is a foundation of OpenBOM:

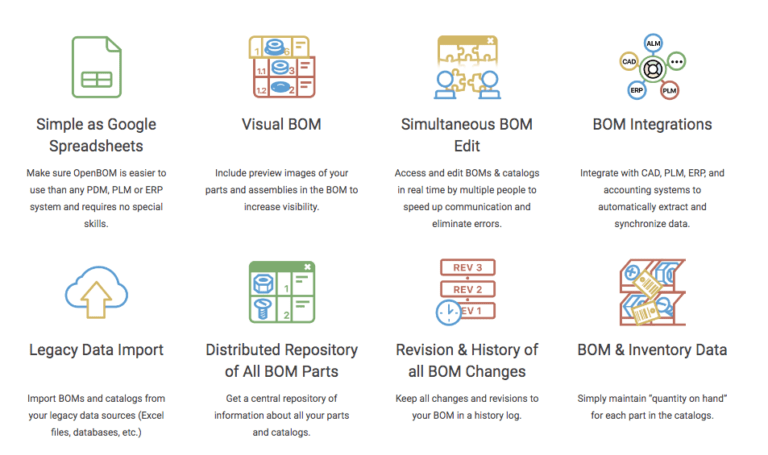

1- Integration with CAD tools.

It is a pain to get data out of engineering tool and all engineering web applications in the past were lacking good CAD integrations.

OpenBOM is integrated with ALL mechanical and electronic CAD systems. Take a look at the OpenBOM website integration page. We can easily extract information from your design and put it on OpenBOM. Even more, we will merge /update this information when your design will change.

Check what CAD integrations OpenBOM supports today.

2- An online (now it called SaaS) applications you can easily log in from any browser

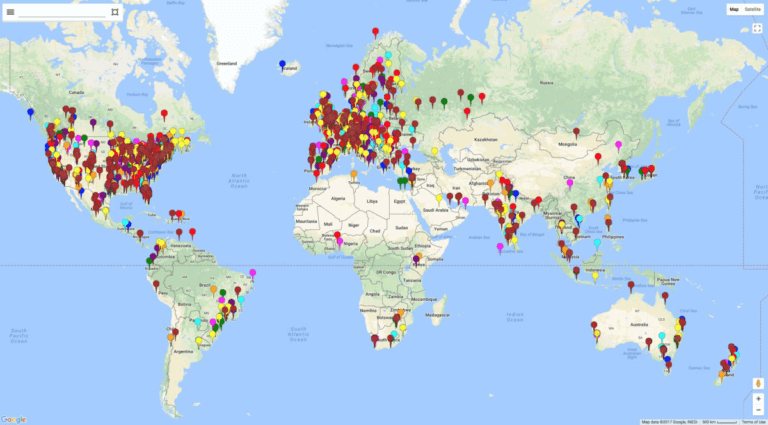

OpenBOM is available globally via the browser in any part of the world. It runs on the most secured infrastructure (Amazon Web Services – AWS) and you can create an account and get access. Check the map on our website – we have users and customers from San-Francisco to Australia and New Zealand. We stopped updating the picture, because we cannot separate multiple dots in Europe and North America.

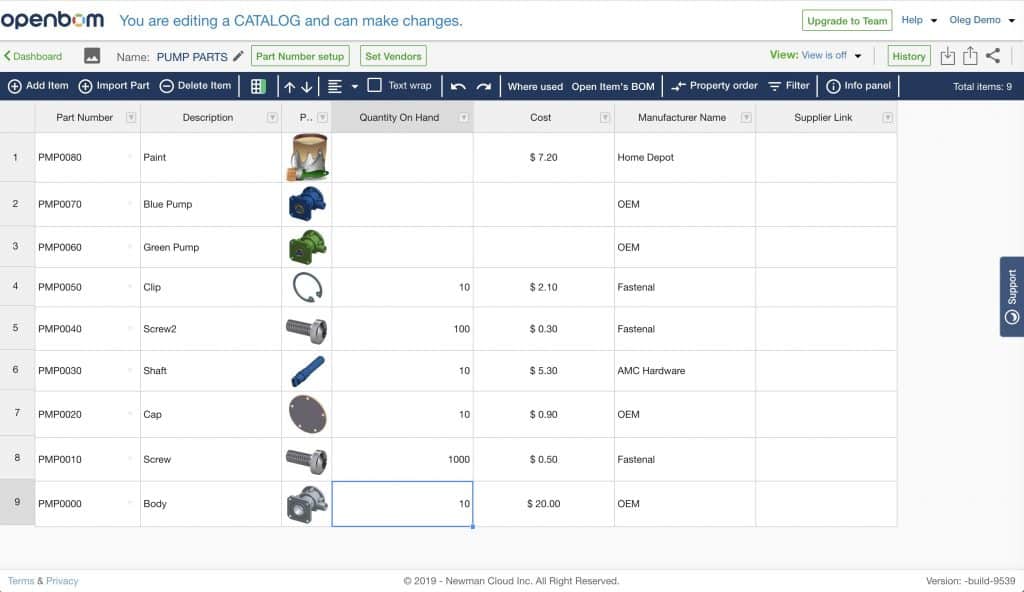

3- User experience as easy as Excel or spreadsheet in data organization, calculations, and search

Take a look at the OpenBOM user interface. It looks and smells like Excel, but there is a sophisticated database system we run behind that simplicity. You can add/delete a column, change the order, add formulas and do almost everything you can do in Excel. All these operations will be translated into product data managed in a structured way.

4- Support core product information data model

OpenBOM information model contains (a) Reference instance to prevent data redundancy (think about one screw copied multiple times in all your Excels); (b) Hierarchical (nesting) to create multi-level BOM, which is a real pain in Excel, without the ability to calculate quantities and rollups.

You can organize data in the way of catalogs – database of everything you have – standard parts, materials, assemblies. The catalogs hold the common information about items – eg. description, manufacturer, cost, supplier. In addition to catalogs, Bill of materials allows you to create a product hierarchical structure. Easy switch between Multi-level and Flattened BOM gives you the magic of BOM with an easy Excel user experience.

Read more OpenBOM Training Library – Understand OpenBOM.

5- Capture changes and manage revisions.

It is so hard in Excel and it must be an embedded function in OpenBOM to manage changes

OpenBOM automatically captures all changes. You don’t need to worry about it. Any change is captured in history and can be reviewed – who did what and when. In addition to that, a special revision mechanism allows you to keep baselines (immutable snapshots) of BOM revision at any moment of time. It works with the hierarchical structure, which eliminates the problems of managing the history of product structures.

6- Visual, easy to share and export.

The value of information is based on how easy it can be shared downstream. We made it “open” – easy to share and consume.

OpenBOM share function works exactly like Google Sheet. You click on share and you can make BOM or any piece of information available to anybody else. You can share information with people working in your company and also contractors and suppliers. You can control who can see which columns and data. A powerful Team view mechanism allows you to control data sharing options.

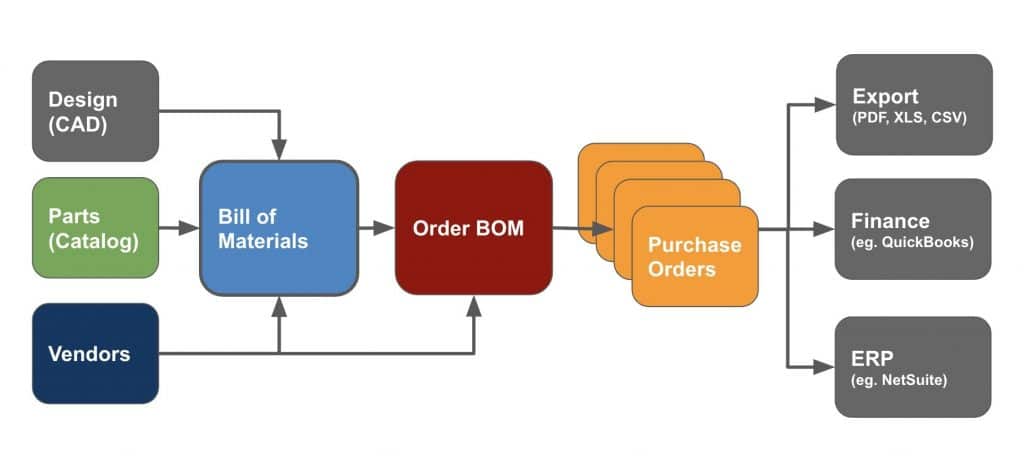

7- Last but very important, OpenBOM is organizing a continuous process for managing Bill of materials, batch orders, and purchase orders.

Here a snapshot of the process

Here is a foundation of OpenBOM process:

Production planning can be thought of as the process, end-to-end, of using your BOM to buy the parts you need. Video of the planning process.

- Assign vendors to items in Catalog

- Calculate quantities based on Bill of Materials for specific product batch

- Manage inventory of parts by controlling Quantity on Hand

- Organizing Order BOM to provide a summary of what needs to be purchased from which vendors

- Automate preparation of Purchase Orders to help sourcing parts and contract work

Join 1000+ engineers using OpenBOM today…

Here are what you are probably asking yourself:

1- Is it safe to put data in OpenBOM?

Yes, it is safe as online bank. AWS infrastructure is secured and we pay great attention to security and privacy. Check our website for terms and privacy statements.

2- Will everyone has an access to my data?

NO, data is securely accessed only by you using your login and password. Until you share the data, NOBODY has access to your information.

3- Can I get my data back if I need to leave OpenBOM?

Absolutely. At any moment of time, you can download your data

4- Will it work with my version of CAD system?

We support most of the versions of CAD systems you might be using out of the box – Solidworks, Fusion360, Onshape, Inventor, Solid Edge, and others. If for some reasons, you have a problem with the version of CAD system you use, please contact support@openbom.com – we will fix the problem

Join 1000+ engineers using OpenBOM today…

All you need to do to escape from messy Excels is to follow these steps:

1- Navigate to openbom.com website to create your free OpenBOM account

2- To collect all Excels you use today to manage your parts, inventories data because these files are great candidates to import all your catalog information

3- Import data to OpenBOM and enjoy a single version of truth about your parts.

3- Install OpenBOM plug-in for your favorite CAD system

4- Generate your first BOM directly from CAD or Excel

5- Use out of the box features such as flattened BOM, rollups and formulas

You should be able to generate your first BOM in a matter of minutes.

Do all these steps in your will NEVER back to Excel or spreadsheets again.

Do more thoughtful work to get more from OpenBOM

- Collect a library of images of your parts- it will make your BOMs beautiful, but most importantly finding parts using visual images will decrease the number of mistakes.

- Plan your catalogs to organize the classification of parts or distribution of parts between contractors and suppliers

- Think about how your team will be accessing OpenBOM (upgrade to Team subscription for unlimited users and organization of Team Views)

- Think how to control Part Numbers in your company and manage lifecycle (upgrade to Company subscription to manage company catalogs and PN uniqueness in your company)

- Check out OpenBOM ERP and accounting software integration

- Automate OpenBOM using REST API to deliver notifications and reports directly to your email or messaging apps like Slack.

Join 1000+ engineers using OpenBOM today…

What Should You Do Now?

Change is hard and I know this. Excels seems to be a safe harbor you love and hate and at the same time. Moving a company to another solution can be painful. Continue with Excel is a pain, but maybe your PDM system you have already can do a job? Also, IT people told you that they can develop a solution to solve the exact problems you have.

Those are legitimate concerns and let me talk about it.

1- How to push an entire company to switch from Excel to OpenBOM?

The truth is that you should not do so. The agile approach is your friend. Think about stages and not one big bang. First, think about how to organize data, extract BOMs and just rely on OpenBOM export to send it to Excel or PDF file and share it with everyone. No pain for others, but I’m sure you will drive their curiosity asking how did you do such a nice BOMs with images and make it all organized. By that time, you will save tons of money and time by stop counting parts. When your colleagues are ready, move on.

2- What if something goes wrong? How can I manage my risks?

OpenBOM has a monthly subscription. We put ourselves on fire and have to convince you to use it month to month. If something goes wrong, your risk is only one month. At the same time, think about how important for us to see you continue with the subscriptions.

3- Can I just use a PDM system?

While PDM systems are great to manage files, they usually suck in item-oriented PLM solutions, like OpenBOM. The ability to manage multi-disciplinary data, hierarchical relationships and business information are absolute winners. Most of PDM systems don’t have flexible parent-child relationships mechanism combined with manual relationships management. You can easily organize multi-disciplinary data in the structures and push it out downstream.

Here are some problems to remember

- Staying with Excel might be good at this moment, but eventually your data and process will become more complex and you don’t want to grow “CEO – chief excel officer” in your company. One day it will backfire for sure

- Relying on PDM might sound like a good option to use the solution you have. But the truth is PDMs are never designed to share information downstream efficiently. Most of PDMs today are archaic database-driven application to manage files check-in/out. No business functions and flexibility OpenBOM can provide.

- IT promises can be a way to create great relationships with IT people, but honestly, you don’t want manufacturing organizations to develop software. The priority and focus on IT will be in the different place long run.

Join 1000+ engineers using OpenBOM today…

Thousands of peoples registered for OpenBOM free user and hundreds of companies are subscribed to OpenBOM premium subscriptions and achieved fantastic results.

Here are a few examples I captured from G2 Crowd Website where you can find real customers reviews about OpenBOM :

1- Small manufacturing business owner:

Recently I started my own business of design and manufacture industrial machines and complete lines for the food industry.

Every machine is custom and has a lot of different references to manufacture. So for me, automate the process to have every part of every machine-controlled is so important. A single error it could represent a lot of money.

With OpenBOM, I’m able to know in every single moment what parts of the machine are the ones that I have to manufacture and the most important, the correct quantity of each.

2- A president of small manufacturing business:

Works great with Autodesk Fusion 360.

It is the only way to easily get a good BOM from a large Fusion assembly.

3- A mechanical engineer in a medium-size manufacturing company :

Very useful and time-saving.

The interface is pretty simple and it allows for a bill of materials to be created easily and efficiently. We were previously using Excel and it was very time consuming and did not have the features that OpenBOM does. The ability to import from Solidworks is also a huge benefit.

4- Consulting partner

Using OpenBOM with Onshape to enable ease of sharing and calculation of sub-totals.

Direct connection of CAD model properties to OpenBOM which enable properties to be updated from either location. The pictures in the OpenBOM cells help to visualize parts and subtotal can be used to calculate product costings.

5- Mechanical Design engineer in small business

Re-engineering inconsistent BOMs in Excel.

The whole idea of live catalogs and pricing all around is a winner. OpenBOM Simplifies this process into an easy to use user interface.

Join 1000+ engineers using OpenBOM today…

Here is what is going to happen if you will be using OpenBOM:

You will create automatically Bill of Materials from the CAD system or import it from Excel

You will eliminate manual tedious reporting, automatic OpenBOM report/export will do the job

You will get rid of annoying calls from people asking you to update the BOM and share it with them because everything will happen automatically

The updates will be easy. Imagine that – you change design in CAD and BOM is updated automatically.

You will finally have FREE TIME not dealing with Excel maintenance

And you can focus on design and stop to be a Chief Excel Officer.

Join 1000+ engineers using OpenBOM today…

So how does it work?

OpenBOM is unique in many ways allows you to manage data seamlessly as a spreadsheet, but then add lot of advantages of structure data management.

Before, when you wanted to create a BOM, you would have to manually extract the data from CAD system. But now, you can use this simple automatic CAD add-ins pulling data from CAD and using OpenBOM flexible data model which automatically creates all properties and fill it with the data from your assemblies and parts, count them and give you a report.

Before, when you wanted to create a BOM, you would have to manually extract the data from CAD system. But now, you can use this simple automatic CAD add-ins pulling data from CAD and using OpenBOM flexible data model which automatically creates all properties and fill it with the data from your assemblies and parts, count them and give you a report.

Let me compare your work before OpenBOM and after you will start using OpenBOM

Before, all tools required installation, databases, IT and setup. But now, OpenBOM is cloud-based SaaS software that is always up to date and can be used from any place using the browser.

Before, when you need to be needed to create Bill of Materials, do reporting and calculations lot of hard work needed to be done. But now, OpenBOM is seamless and easy like Excel and hide all complexity behind intuitive and modern user experience.

Before, when you managed BOM using Excel or old tools, you were only able to rely on text. But now with OpenBOM you have a visual Bill of materials which automatically pull images with part and assembly previews which simplify selections and eliminate mistakes.

Before, import from CAD was manual. Now with OpenBOM, CAD add-in can do this work automatically and painlessly. Each BOM starts in CAD and we automate and simplify this starting point for you.

Before you had to pull data and to make formulas in Excel. It was hard and didn’t provide rollups and complex calculations needed for Bill of Materials. With OpenBOM you can make calculations and rollup in hierarchical structures. Also, OpenBOM centralized data about parts such as cost, mass, etc. making changes easy for formulas.

Before, when you manage BOM using Excel to have both structured and flattened BOM was impossible. With OpenBOM you have an automatic switch between single level, multi-level and flattened BOM.

Most of the data management systems for BOM are inflexible. So, when you needed to add some specific data you were not able to do so. Therefore everyone likes Excels. OpenBOM will bring both of these worlds together – the flexibility of Excel and structured data management needed for BOM.

Importing data to all data management and BOM management system is hard work. Not with OpenBOM. With OpenBOM we automatically import any legacy data directly from Excel to simplify the process of migration and integration with other systems.

Before OpenBOM you should have been sent an email with Excel attachment to share the data. With OpenBOM, you can share BOM and related data in a real-time and do simultaneous data updates.

Excels doesn’t give you a way to structure queries like composed of and where used. With OpenBOM, you have automatic full-text search and where used functions.

To update data in BOMs coming from the external system is a hard and manual task. With OpenBOM with automating data merge and update. You just need to click on the import button and updates will be merged in.

Finally, before engineer was a person to blame for mistakes in Bill of Materilas. And these mistakes are costly. So engineers have to do manual tedious tasks. Not anymore. With OpenBOM you won’t be blamed for BOM mistakes.

Join 1000+ engineers using OpenBOM today…

What if you continue to use Excel?

If you will continue to manage BOM using Excel, it will cause you lot of manual activity, spent time and potential mistakes. It can cost a fortune to you manufacturing business as a result of delays, wrong parts orders and endless communications.

You can subscribe to OpenBOM for a fraction of the cost you paying for mistakes

You can subscribing to OpenBOM professional subscription (in the range of $25 to $375) depends on the features you would like to use.

Here is what you get:

1- An online tool in the browser to manage your parts, bill of materials, vendors and purchases

2- Automatic data extraction from CAD and other systems

3- Calculations and rollups

4- Share data with everyone you need either online or using export to Excel/PDF/CSV

5- Create shopping lists or reports that can be provided to purchasing and procurement.

And all you need to do is TO REGISTER TO OPENBOM AND PURCHASE A SUBSCRIPTION.

Here is what you do;

Navigate to OpenBOM website- openbom.com and REGISTER FOR FREE

Purchase a subscription or request a trial using THIS LINK.

Install CAD add-in for automatic data extraction.

And you are done!

Every day that BOM management is done in Excel, the problem is not solved and your company is losing tons of time and money. I have a BONUS for you.

Because you are reading this message and you got so far, I’d like to do something special for you. For a limited time, we are going to offer you a free 2 hours of consulting and strategy call with me, which is the value of $500 to help you with any questions related to organizing your information and better use OpenBOM.

Let’s talk about risks…

The risk of using OpenBOM is very low. You can use OpenBOM monthly subscription and you can cancel it at any time. So your risk is literally $25, which is the price of a very good lunch.

Here is my OFFER for you.

You will get…

1- An online tool to manage Bill of Materials, parts, catalogs, vendors and purchases

2- Ability to automatically extract bill of materials from CAD and import data from Excel

3- Manage nested (multi-level) BOMs, changes, revisions, make calculations and rollup

4- Share data with everyone and eliminate mistakes of emails/Excel

5- Two Hours special consulting web meeting

Still have questions?

Here are some typical questions engineers are asking me about OpenBOM:

Q- Will it work with my complex CAD assembly

A- Yes, any data can be imported from CAD to OpenBOM

Q- Will it work with my version of CAD system

A- Yes, we support all CAD systems. If a particular version won’t work, we provide a fix asap

Q- Will it work in my country (eg. China, Europe)

A- Yes, OpenBOM is available globally

Q- Will it automatically shares data with everyone who is using OpenBOM

A- NO, the BOM access is secured and ONLY YOU have an access, unless you share it with your colleagues and contractors

Q – Will it share data automatically with my team

A- Yes, Team subscription does it

Q- Will it update BOM once it is extracted from CAD system

A- Yes, BOM will be updated and merged based on changes you do

Q- How do I know, the data is secured and won’t be shared / sold?

A- Read our terms of service and privacy statement online (link)