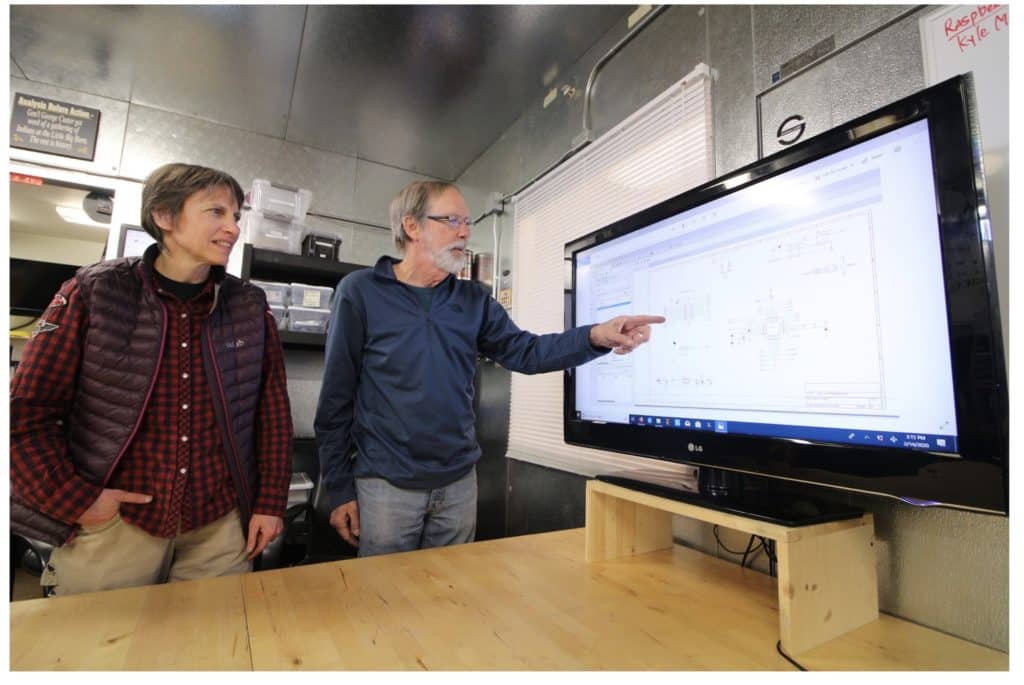

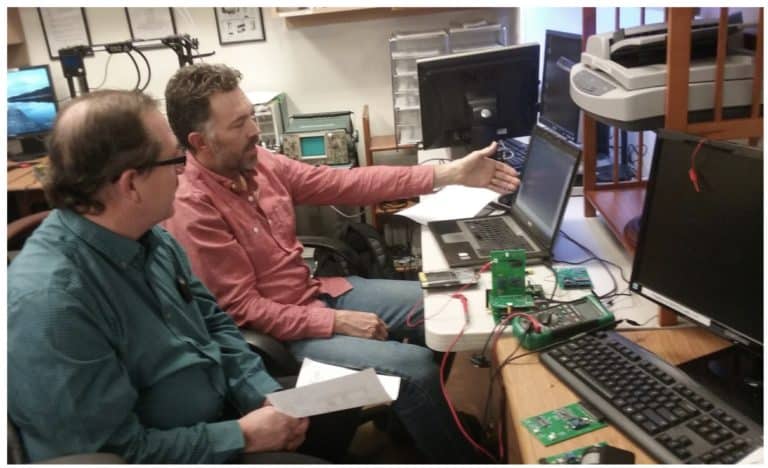

David Robson and Rick Silver founded E::SPACE Labs as a technology incubator with the goal of providing folks in the Bend Oregon area access to engineering and design tools and services and to foster and promote high-tech innovation in the region – after 5 years they have done so much more. They have built E::SPACE Labs into a nimble team of multi-discipline engineers (6 Electrical Engineers, 2 Mechanical Engineers, an Industrial designer and 2 technicians) capable of delivering complex high-tech prototypes as “ready for manufacture” turn-key packages.

And they chose OpenBOM to help them do it! Here’s how…..

According to Co-Founder David Robson “we currently have twelve projects in flight with 6+ active clients each with their own set of needs and requirements. We needed a secure site for BOM data as we were literally tripping over ourselves trying to do it in Excel.”

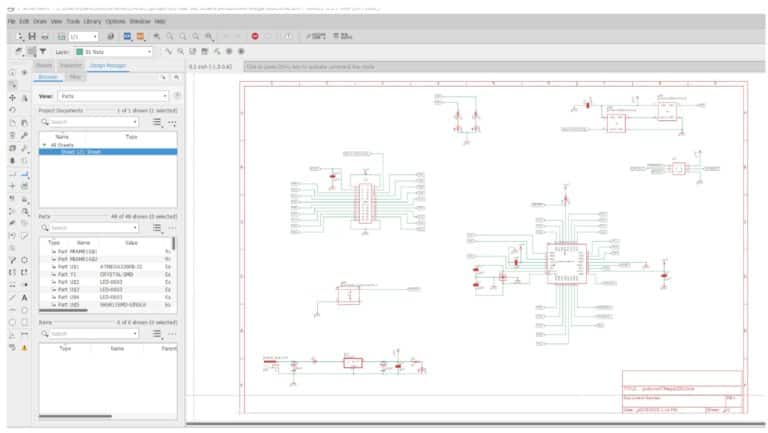

E::SPACE uses Autodesk Eagle for PCB and schematic design and Fusion 360 for mechanical and industrial design, their designs can be complex with electronics, software and mechanical components all in a single package.

“The multi-disciplinary aspect of OpenBOM and the only one of it’s kind integrations to Eagle and Fusion 360 save us valuable time and greatly improve accuracy and reliability” David goes on to say.

“We are big fans of Autodesk which is one of the reasons we chose OpenBOM. OpenBOM fits nicely into our technology stack which also includes Google Docs for specifications and Bitbucket for software and firmware” he says.

E::SPACE relies on OpenBOM to build a reusable catalog of items and components for the next guy doing a new board or product. “We try to limit the number of different components for the economy of scale – standardize on a few components for each catalog. As our designs progress, our OpenBOM catalog evolves and becomes more mature and valuable.”

OpenBOM is easy to use, he says, and “the OpenBOM support is superior to every other product we buy.”

E::SPACE Labs services run the spectrum from ideation to manufacturer ready prototype and E::SPACE clients have several patents (and applications) including one recently by Graham Hauser who defines himself as a big “Espace fan”. David will be using the OpenBOM Team function to enable Graham to share design data with the E::SPACE engineering team and (future) manufacturing partners. Graham will manage his product as he transitions to high-volume manufacturing with OpenBOM.

Graham and the other E::SPACE incubator clients like the way OpenBOM tracks and manages vendors and second sources as parts change or obsolete.

“Finally,” says David, “as the product goes out the door to manufacturing we share the OpenBOM with clients and contract manufacturers, which gives them confidence in the E::SPACE work and pace of development and gives us a head start on any future ECO or revisions they request. OpenOBM has given E::SPACE a step up on providing our clients with professional engineering documentation”

For more information about E::SPACE Labs please visit www.espacelabs.com

To learn more about OpenBOM please visit openbom.com

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.