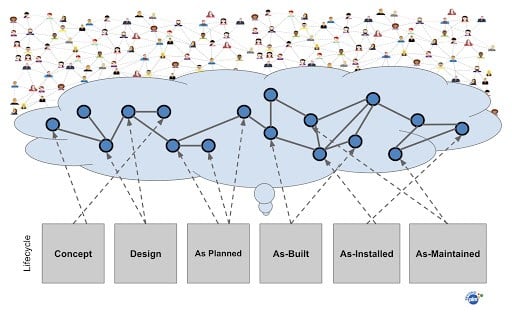

The PLM is an abbreviation that stands for Product Lifecycle Management or product life cycle in a more wide aspect of the definition. In the engineering and manufacturing industry, PLM is an overall process of managing information about products across the entire lifecycle. It covers requirements, design, engineering, manufacturing, production, support, maintenance, disposal, and re-fabrication.

What is Product Lifecycle Management (PLM)

If you’re in the manufacturing business, product’s life cycle is a critical function that traces changes of the product from the early stages of ideation to later stages of maintenance and support. I’m sure you’ve heard about PLM (Product Lifecycle Management). And the thing you probably heard is “PLM is for large companies”. As far as you are concerned about your hardware startup business, you might think PLM is not important and you can do it later. This is can be true when you work in your garage on some prototypes. However, as soon as you start thinking about how to bring your product to at least a handful of users, you can find that following some basic PLM principles can save you time, money and help to bring products with the right cost and quality.

PLM is taking its roots from the engineering functions of large aerospace, defense, and automotive companies. These are complex environments with a very nontrivial process to manage. These industries and engineering roots of PLM made it complex. It doesn’t mean PLM should be a complex.

Product Life Cycle in OpenBOM

The production life cycle definition starts from the information. Product information is a foundation of design, planning, and manufacturing. How to manage it efficiently? How to define the lifecycle of a product.

You can easily export data from CAD to Excel, but you will spend a lot of time making updates, especially if you will add more data such as cost, suppliers, planning, and other pieces of information.

Data sharing is another challenge. Send emails with Excels is easy, but finding the right Excel is hard. You will make mistakes and your team will end up using the wrong Excel.

Think about counting unique parts in multiple CAD assemblies. It is tons of work. And if you add more items added outside of CAD, you can spend hours doing it and you will make mistakes.

Rollup cost is another level of complexity, translating unit of measures used in BOM to purchasing units will turn you in chief excel officer.

Manual tracking of change history, revisions, and managing change approvals will slow down processes and will lead to mistakes.

So, you end up with wrong parts, purchase orders with mistakes, delays, additional cost, hard time to forecast, lost opportunity to use volume orders, and many other problems. Sending wrong information to contractors can be even more expensive and disruptive for business. Your team working with the wrong information will spend more time working on the wrong design and product planning.

The root cause of all problems I described above is inefficient data management. To organize and manage data in a modern distributed environment is a challenge that cannot be solved using traditional database systems or file servers. OpenBOM provides a uniquely flexible and scalable approach in data organization to manage different aspects of the product development process, change management, quality management system, maintenance, purchasing and others.

These are the top 5 things that create a unique value proposition of OpenBOM:

- Product record and a single version of the truth. OpenBOM creates unique data records for all items and corresponding information – Part Numbers, descriptions, revisions, cost, manufacturer, suppliers, lead time, etc. BOMs are using items and extend it with usage information (eg. Quantity, Project). OpenBOM data model is flexible and you can extend it at any time. The extension is a big deal as it allows to every company to be different, yet provides a way to organize the data.

- Automatic BOM creation and updates from any CAD systems. You won’t count manually anymore. A single click on the button will create BOM and update it when you do it next time. All changes are tracked and revisions can be created

- Automatic quantity calculation, formulas, and custom rollups. You can combine multiple assemblies into a single multi-level BOM and automatically calculate everything you need for planning and purchasing.

- Instant data sharing mechanism with a click of the button or automatic role-based sharing using team views. OpenBOM instant share and Google-sheet like collaboration and simultaneous editing will guarantee you have all information up to date shared with everyone.

- Out of the box purchasing planning process. OpenBOM creates an Order BOM (planning BOM), which can scale the quantity to the level of the order, keep track of stock level (quantity on hand), and automate the process of purchase order creation.

Example of a Product Life Cycle

How to organize product information using OpenBOM? The following example will demonstrate to you what means to build a product lifecycle in OpenBOM.

OpenBOM helps you to organize information about the product. As much as it sounds simple and obvious, the organization of the data is one of the most important and complex processes to accomplish in the organization. Even the smallest organization with just a few people can create an enormous amount of complexity by not organizing data.

So, where to start?

As I always say to our customers, if you have a mess, don’t bring the computer to the mess. Because it will create a “computerized mess”. You need to clean the data, think about data organization, classification, storage, semantics, files, and many other things. But, don’t worry, it is not as complex as it might sound in the first place.

Here is a process we recommend to have when you start working with OpenBOM to organize data and properly capture the information you have in the company.

1- Identify the existing data sources

It is very important to start with the data in- the first step. How the data is created, what systems are used to generate the data. If information is created manually, then who does it and who control the data sources. The data source can be an excel file, it can be an export from an existing system or it can be CAD files or local databases. To find all data sources, to decide what to do, what information will be transferred to OpenBOM, and what information will stay with existing data sources, how data will be exported, and synchronized is the first step to understand how to organize data.

2- Classify items and the way to collect item information

Classification of information is the process of identifying what pieces of information need to be managed and how to identify data. A typical process of information classification includes defining of Part Numbers and typical attributes that managed on the item level and instance level.

Item information represents the data that is the same for all usages of the item (think description, cost, manufacturer, etc. Data is organized in catalogs and the OpenBOM catalog defines the set of attributes for all items stored in this catalog. A set of catalogs is a classification schema. Classification can be different for each company. Usually includes, including types of items (standard, engineering), can include contractors or any other specific ways to classify.

3- To define a continuous process to create items

Once you identified sources of item information you need to decide how to manage this information. The main part of the process is to create an Item. In OpenBOM you can create items in multiple ways. The easiest and simple one is just adding an item to the catalog manually. Similarly, if you need to add an item directly from CAD system, you can use OpenBOM CAD Add-in “Save Item” command.

Another way to add items is to get them continuously imported to the catalog using Import Command. Catalog import is a powerful tool to import new item data and also import some other and merge it with the information about available items.

The last method, you can think about is to save “Create/Update Catalog” commands from OpenBOM CAD add-ins. This command can take an entire set of parts and sub-assembly in a specific design and export it to a catalog.

4- To organize access control and change process for items

OpenBOM access control is based on data ownership and sharing settings. If you’re a single OpenBOM user, nobody except you has access to items data by default. In order to get access, you will need to share the data manually. You can share with anyone who has OpenBOM account using the Share command.

If you’re part of the OpenBOM Team or Company, you can share automatically the data. The default access levels are none, read-only, edit, and View. The last method involves the definitions of Team Views. Each user in the team (or company) will have a list of applied views and the list will restrict the data access.

Recommended webinars and articles:

How to Manage Data About Parts in the Bill of Materials

How many catalogs should I create in OpenBOM

Benefits of working with OpenBOM

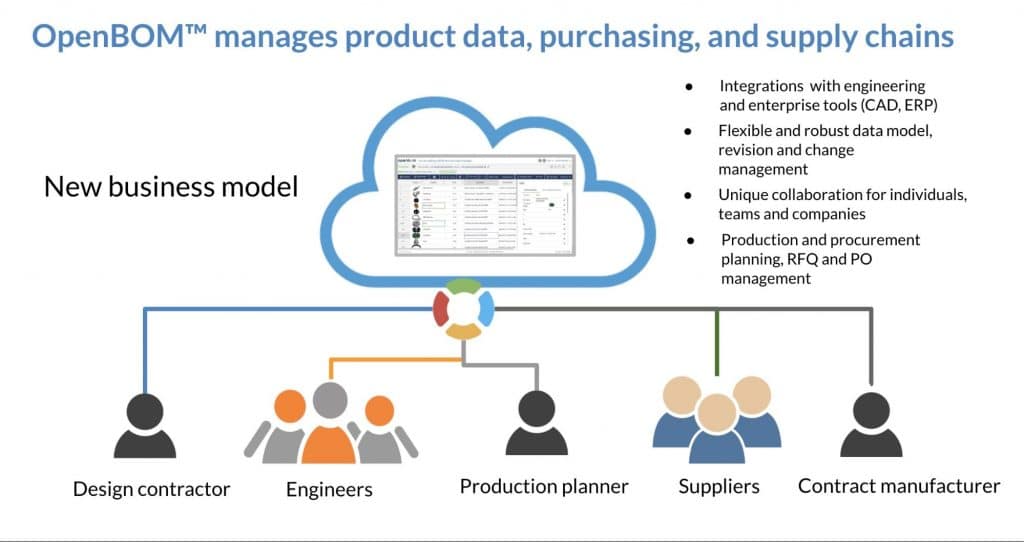

Our vision at OpenBOM was to change the status and democratize PLM systems by following these 3 steps:

1- Use the cloud and SaaS as a foundation. No IT, no custom deployment, you can create an account in a matter of minutes.

2- Tight integration with Design and Engineering software. CAD systems are the foundation and the source of information for BOM and PLM. So, creating integrations can streamline the data and simplify the process.

3- Integrate downstream processes. Starting with production lifecycle, planning and purchasing, OpenBOM provides an integrated mechanism to connect engineering information and drive the purchasing process (POs generation and batch planning).

When Excel and email are the ways to communicate, companies can face tons of challenges – lost files, impossible to rollup cost, wrong information manually places in Excels, merging information from multiple suppliers, sending wrong files to contractors, getting access to drawings and many others.

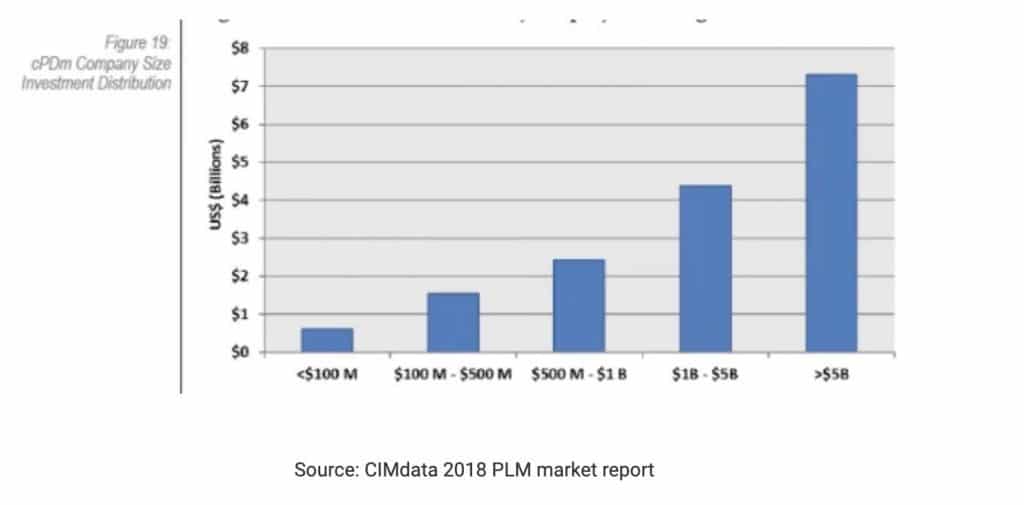

While PLM software vendors are talking about PLM technologies as a “single version of the truth” for manufacturing for ages, this PLM systems and implementation are still the unachievable dreams for many manufacturing companies. Especially when it comes to small and medium manufacturing companies.

Check Beyond PLM blog – PLM for SMB: Business, Market and Numbers, you can find an interesting data point about the distribution of PLM sales between companies of different sizes.

This is a reason we built OpenBOM – to solve the problem of communication and data management for small and medium-size manufacturing companies to optimize their production process, managing data and communicate between teams and people located across the globe.

A single version of the truth

Product information is a foundation of design, planning, and manufacturing. How to manage it efficiently?

You can easily export data from CAD to Excel, but you will spend a lot of time making updates, especially if you will add more data such as cost, suppliers, planning, and other pieces of information.

Data sharing is another challenge. Send emails with Excels is easy, but finding the right Excel is hard. You will make mistakes and your team will end up using the wrong Excel.

Think about counting unique parts in multiple CAD assemblies. It is tons of work. And if you add more items added outside of CAD, you can spend hours doing it and you will make mistakes.

Rollup cost is another level of complexity, translating unit of measures used in BOM to purchasing units will turn you in chief excel officer.

Manual tracking of change history, revisions, and managing change approvals will slow down processes and will lead to mistakes.

So, you end up with wrong parts, purchase orders with mistakes, delays, additional cost, hard time to forecast, lost opportunity to use volume orders, and many other problems. Sending wrong information to contractors can be even more expensive and disruptive for business. Your team working with the wrong information will spend more time working on the wrong design and product planning.

The root cause of all problems I described above is inefficient data management. To organize and manage data in a modern distributed environment is a challenge that cannot be solved using traditional database systems or file servers. OpenBOM provides a uniquely flexible and scalable approach in data organization to manage different aspects of the product development process, change management, quality management system, maintenance, purchasing and others.

Engineering Integrations

The core fundamentals of PLM are integrations with engineering systems such as CAD. OpenBOM support out of the box CAD integrations for many CAD systems. Check more here for all OpenBOM integrations (openbom.com/integrations). Also, check details about out of the box OpenBOM integrations and sample videos how to start using them.

Navigate to OpenBOM Change Management Help to learn more about how OpenBOM helps you to manage revisions, changes and approvals.

OpenBOM Change Management and Change Requests