The folks at Texas-based Stone Aerospace are modern age explorers! Their team of seasoned expeditionary scientists and explorers develop the tools needed to explore, survive and work in the most extreme environments imaginable. The SUNFISH® vehicle was developed in collaboration with NASA for a future exploratory mission to the Jovian moon, Europa. This autonomous underwater vehicle is designed to explore the ocean beneath more than 15 km of ice and gather data autonomously from the alien world.

As the project demands grew, and their SolidWorks dataset increased in complexity, Stone Aerospace realized they needed a way to manage Bills of Materials and Purchase Orders beyond what Microsoft Excel could offer.

“We evaluated a number of options and chose OpenBOM.” says Scott Lelievre, Mechanical Engineer with Stone Aerospace.

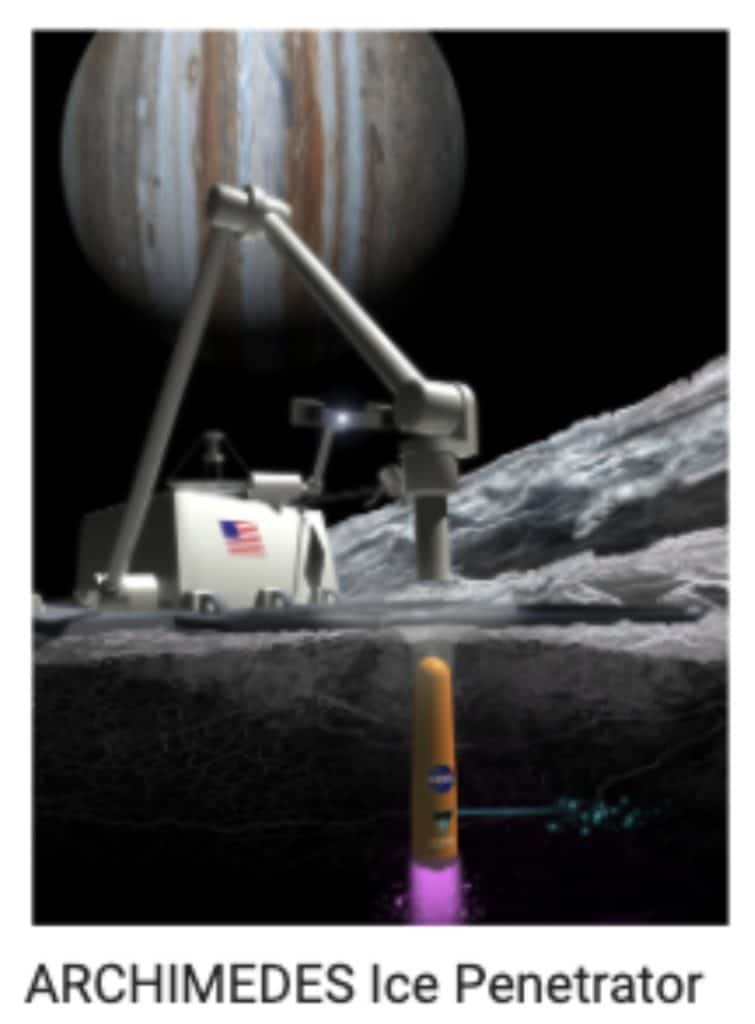

Beyond SUNFISH, Stone Aerospace has a number of other projects like the ARCHIMEDES direct laser ice penetrator, and the DepthX underwater vehicle, both developed for NASA for similar Europan missions, and all with many varied and complex systems onboard.

Stone Aerospace prides itself on being able to take advanced concepts from the drawing board to field demonstration extremely rapidly, meaning that tracking complex one-of-a-kind assemblies from design to fabrication and assembly is critical.

“We needed help organizing parts and assemblies and tracking what has, or will be ordered,” says Scott. “Our CAD data is saved into OpenBOM Catalogs using the Solidworks add-in, then we organize BOMs, Order BOMs and Purchase Orders which reference the Catalogs. That way a single master exists for each part or assembly which can then be used in many BOMs.”

Stone Aerospace uses the extremely flexible data model of OpenBOM to add additional properties to their Catalog(s) which they regularly update once RFQ’s are created and PO’s are placed, thus creating an ad hoc closed loop to track PO Status.

“Before OpenBOM we had no system for tracking PO’s, RFQ’s and BOM’s. We really had almost no PO system. With the implementation of OpenBOM we can actually follow the design cycle from cradle to grave, know when parts are due, costs of those parts and the stock status. That to me is a lot more impressive than just decreasing PO creation time.”

To learn more about Stone Aerospace please visit https://stoneaerospace.com/

To learn more about OpenBOM please visit openbom.com

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.