Since its founding in 2014, Questum’s E-Mobility division, Atmovum, has been developing technology for sustainable urban mobility and OpenBOM is an important part of their success.

Based in Monterrey Mexico, I recently sat down with José Elías Gallegos Arguijo (Elias), the company’s System Engineering and Electrical Integration lead, and Alfonso Gerardo Porras (Alfonso), their Product Structure Engineer, to learn more about the specifics of just exactly how E-Mobility designs and produces products dedicated to this space and where OpenBOM fits into their process.

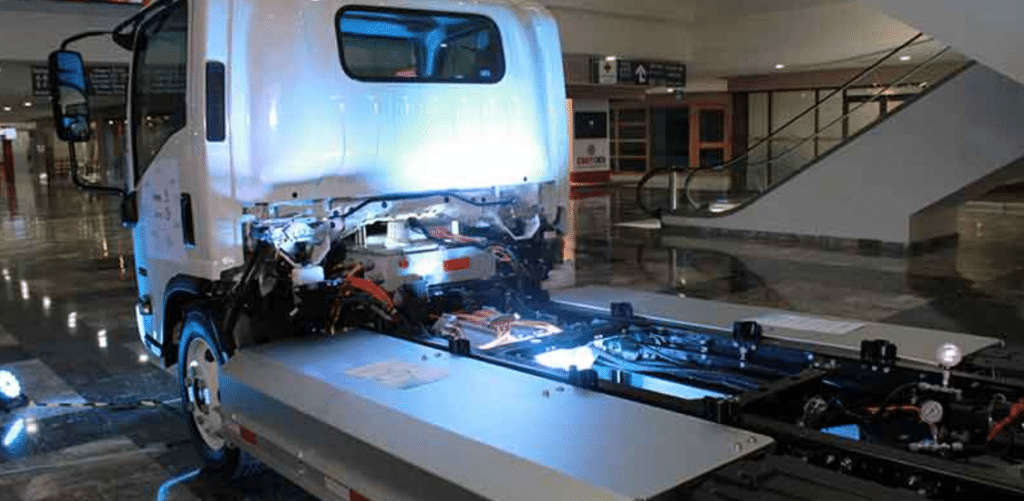

“Our primary product is medium-duty truck conversions from diesel to electric,” says Elias. “We produce a platform to convert from diesel to electric.”

Atmovum works only with OEMs, and only on new units, providing diesel to electric conversion services to industry-leading truck manufacturers.

“Our product is complex”, explains Elias. “As our company and offerings grew, management of all these parts was becoming a burden. We had started with Excel and quickly realized that was not going to scale.”

Atmovum, like many rapidly growing companies, needed to leverage their existing Excel BOMs and planning documents, while implementing a new way of working, all without disrupting the production line.

“We needed something else, we were moving to Onshape cloud-CAD and we wanted a manufacturing planning partner product that did not break the bank,” says Elias.

“OpenBOM was a natural fit, tight Onshape integration, great manufacturing features, and it blended right into our commitment to cloud.”

Elias went on to tell me about their journey for a new toolset & process.

“We evaluated PDM but realized we didn’t really need what was offered. We invested time and effort to benchmark many PDM/PLM systems, Windchill by PTC, Autodesk, Dassault, and more.”

Elias went on to say, “we asked them all HOW DO YOU MANAGE BOMs? Most could not explain how their classic systems did BOMs. It got very complicated very quickly- all about “Objects” and complexity…. It quickly became customization and cost. It was clear we would need a dedicated BOM engineer in a classic system, that was not in our plan.”

Product Structure Engineer Alfonso Porras explains it in very simple terms, “we moved our excels to OpenBOM using the import feature, built our catalogs from existing BOMs so we had an item master, then organized our items into catalogs to help us divide and accurately assign our part numbers.”

“Then we simply built our BOMs in OpenBOM from our items.”, explains Alfonso.

Alfonso went into specific detail about how Atmovum uses the OpenBOM Catalog structure to organize items by category, a Catalog for each category; 1) Design, 2) Components, 3) Commercial/buy, 4) Hardware/fasteners/clamps/washers, and 5) Assemblies.

According to Alfonso, “our BOMs are much faster to produce, are more reliable, and afford much more reuse than the excel-based process.”

Elias explains, “we have a lot of existing BOMs which we can easily leverage. Our catalog structure helps us build BOMs more reliably and easily share major (functional) sub-assemblies like an entire power train between BOMs. Just enter the part number for a power-train sub-assembly and the entire structure flows into the new BOM.”

Alfonso and the Engineering team rely on the functional group part numbers in the Catalogs to quickly locate sub-assembly BOMs and drill down to specific parts quickly.

“I love the right-mouse-Open Item’s BOM command in the Catalog!” he says. “It takes me right to the BOM for any part number.”

In addition to the ease of BOM creation and management, Atmovum relies on the BOM revisions feature in OpenBOM to create traceability and history.

“BOM revisions are easy in OpenBOM, we plan to start using the new Item revision very soon,” says Elias.

Finally, the Onshape integration makes it quick and easy to go from a new design in CAD to a BOM in OpenBOM.

“The make-from workflow in Onshape/OpenBOM saves us time,” says Alfonso. “We open an existing project in Onshape, make changes, assign a new part number to the top level, export the BOM, and we have a new BOM which is a mix of new and (re)used items and sub-assemblies”.

To learn more about Atmovum please visit www.questum.com/en/mobility

To learn more about OpenBOM please visit www.openbom.com

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.