“Build With Robots takes the danger and drudgery out of mundane and awful tasks while elevating workers.” A bold statement from Build With Robots and one that all of us at OpenBOM share.

Founded in 2017 with a mission to make workers’ lives better. Serial entrepreneurs Chris Ziomek and Matthew Ennis believe in the dignity and value of work.

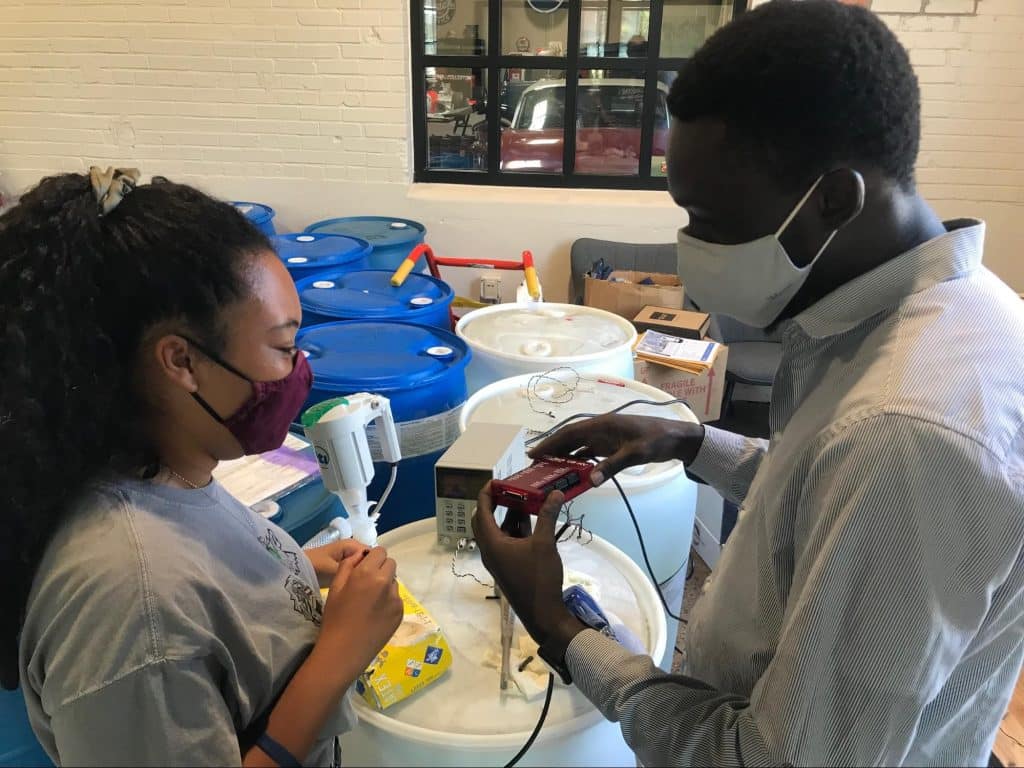

As such, Build With Robots designs and manufactures robots that operate alongside workers to perform dangerous tasks such as disinfecting and other chores.

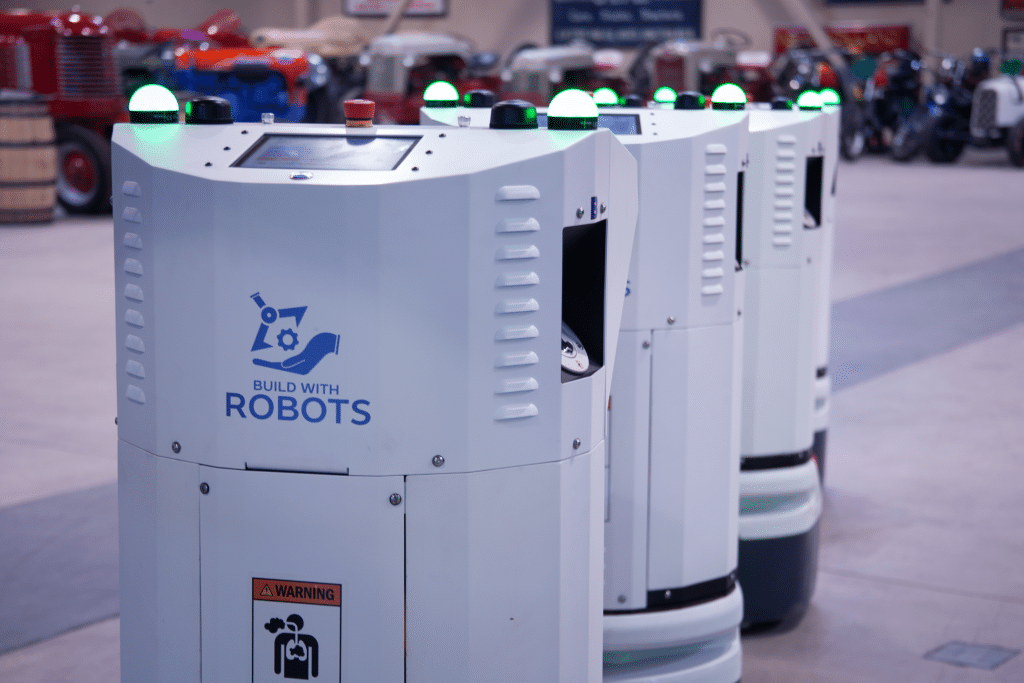

The very capable Breezy One™ is such a robot.

Produced in the company’s Albuquerque, New Mexico, facility, the Breezy One™ takes the danger out of disinfecting large public areas like schools, airports, stadiums, and other facilities where “spraying” may not be an option. For context, electrostatic spraying is extremely labor-intensive and costly. Breezy eliminates both of those burdens and has the added bonus of consistency, leaving no room for human error and missed areas.

Presently in use at the Albuquerque International Sunport, Hobby International Airport, and George Bush Intercontinental Build With Robots is expanding into schools in New Mexico, Texas, and Arkansas. The Breezy One™ is currently in use at the University of New Mexico Basketball stadium (the PIT).

The company’s Director of Product Engineering, Ryan Martin, is responsible for the overall product delivery and quality and is tasked with scaling capacity as the business quickly grows.

As Ryan explains, “We could make 10 or 15 robots but when demand scaled by an order of magnitude, our existing Excel process just did not meet our needs.”

“What revision are we making?”, was a common question, says Ryan. The company was faced with the immediate challenge of managing changes and updates.

“We looked at a number of products before settling on OpenBOM”, says Ryan. “We were familiar with Pedyn but the onsite server requirements of an installed system did not fit our strategy, which is to be scalable and lightweight.“

“Arena was also a contender but we settled on OpenBOM for a number of specific reasons, the pre and post-sales support from the OpenBOM staff was outstanding while the OpenBOM product features, value, and workflow fit perfectly into our business process.”

“We also enjoyed the benefits of the Onboarding process,” he says, “OpenBOM is now helping Build With Robots find a sustainable path for product development, manufacturer interactions, and lifecycle management”.

Make no mistake, the Build With Robots products are sophisticated.

Designed to travel along predetermined routes initiated by facilities crewmembers, the robot is guided by Lidar, and Cameras all in a connected environment using wifi and cellular for communication.

“There is a lot of information that must be communicated to our contract manufacturers and suppliers”, says Ryan.

“One of the benefits we realized immediately with OpenBOM is that our engineering and operations teams spent considerably less time searching for the latest released drawings, and specifications.”

Build With Robots links all their specifications to the bill of materials which is widely shared with all stakeholders.

Access and revisions are also controlled ensuring everyone is on the same revision of the BOM.

Our contract manufacturers are all domestic United States”, explains Ryan. “We release a bill of materials in OpenBOM, and use the OpenBOM ZIP package export command to create a single archive containing all the files and specifications for the entire product at the proper revisions.”

“If we need to update, we just update, then send an updated Zip file with a new revision on it. It’s that easy.”

Build With Robots’ BOM process is reliable and repeatable and has improved their quality as they scale.

As explained earlier, Build With Robots products are complicated and contain a variety of engineering disciplines.

“OpenBOM is the system of record which defines our product. Non-modeled items are added in OpenBOM, Circuit Boards from Fusion 360 are integrated easily with Mechanical BOMs to create a single multi-discipline top-level BOM.”

Ryan continues, “OpenBOM adds flexibility to the purchasing process. We use multiple vendors for PCB and hardware, track which vendor has been approved, which contract manufacturers and hardware suppliers are selected for a particular process, like sheet metal for example.”

“As Build With Robots goes into HVM we will be looking more to contract manufacturers to support us. We will rely more on OpenBOM as we integrate CMs into our team.”

Ryan and Build With Robots are laser-focused on quality.

“Most important is the value our customers receive. Our decision to buy OpenBOM means we have better insight into what we are building and as we scale we will bring increased quality to our customers.”

To learn more about Build With Robots please visit www.buildwithrobots.com

LinkedIn – Build With Robots , Twitter – BuildWithRobots , Instagram – BreezyOneRobot

To learn more about OpenBOM please visit www.openbom.com

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.