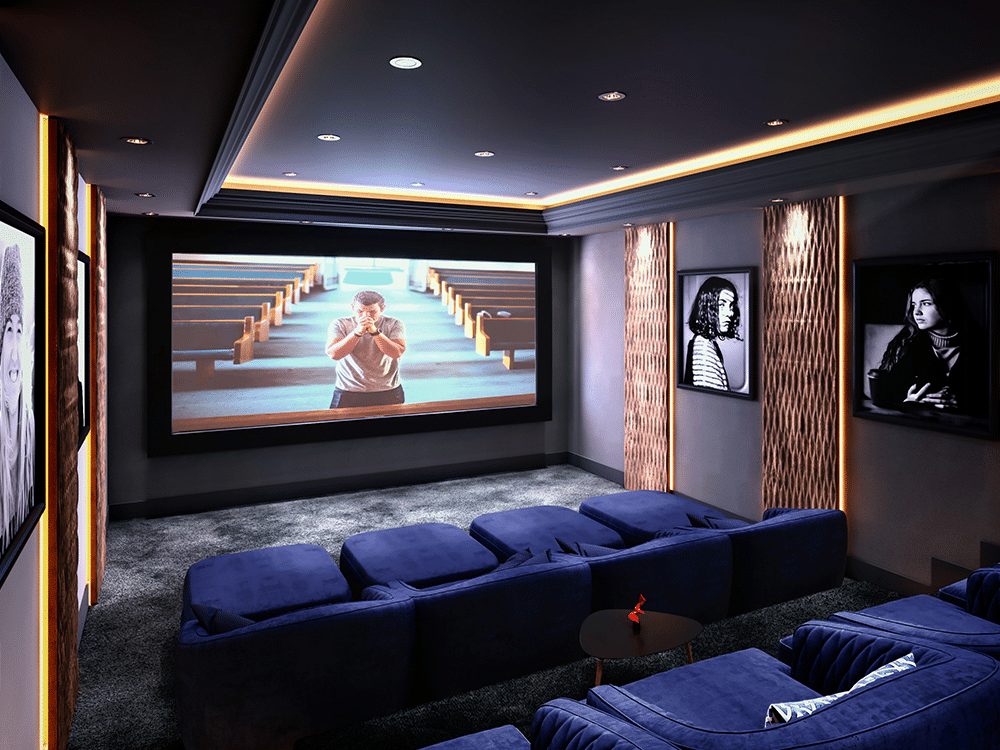

Northern England’s Display Technologies LTD. is a manufacturer of high-end theater room projector screens and related equipment for high-end residential audio/video installations.

According to the company’s Technical Director Simon Ridley, “our customers are the people who build and install extremely high-end media rooms, worldwide, and we love how OpenBOM helps us do that.”

Display Technologies’ origins can be traced back to one evening in 2016 when Simon and his team, who have years of experience in this industry, were sharing a pint at a local pub when someone proclaimed “there has got to be a better way”.

Well, as it turns out, there was!

So Display Technologies LTD was formed with the goal to simplify the complex, non-uniform, and often disparate components of the high-end media room business and to do so from an installer’s point of view.

“We approached this challenge from the installer’s point of view,” says Simon. “With the overarching theme to Design for Installation from the ground up.”

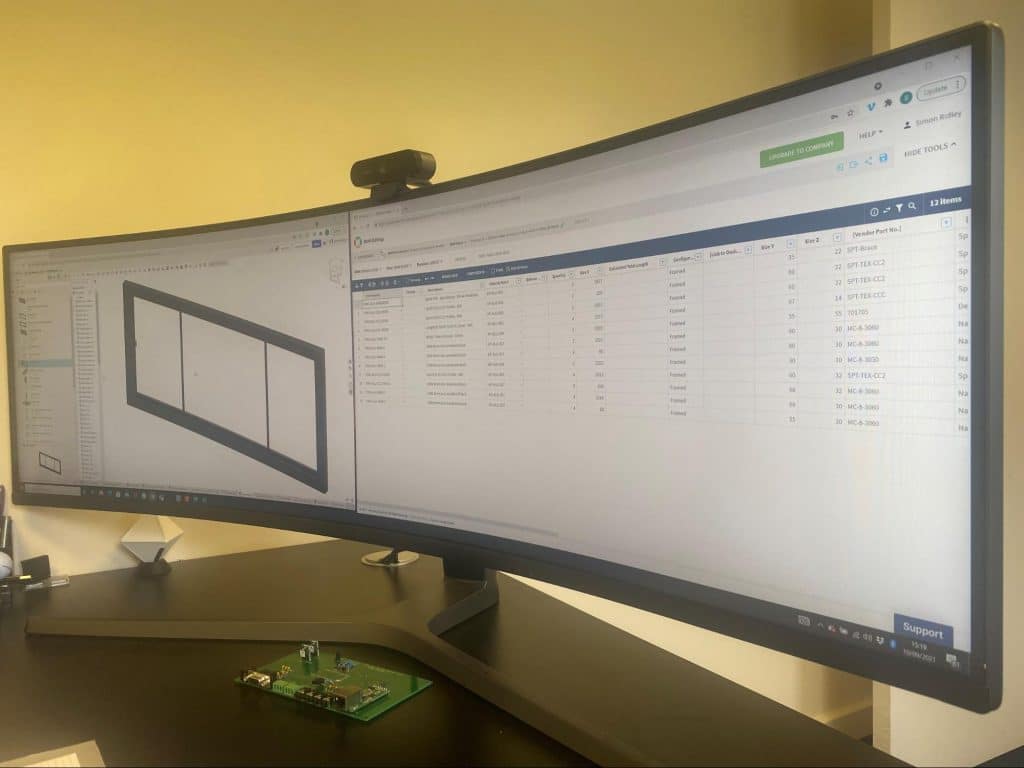

Having a strong background in IT, Simon quickly decided that the company’s technology stack should be built on SaaS, and not necessarily on conventional (old) installed design and business tools.

“We run the company on SaaS”, says Simon, “from design to manufacturing and all the business operations, they are SaaS. We Love how OpenBOM fits into our technology stack.”

From the get-go, Simon and his team relied on OpenBOM.

“We chose to skip over the entire Excel phase of growing a business, going straight to Onshape for CAD and OpenBOM for BOM and manufacturing planning”, says Simon. “We focused on making good decisions up-front and never being trapped in Excel, consequently we have been using OpenBOM from the very beginning.”

The bottom line is we love how OpenBOM plugs right into Onshape, but that’s just the start.

“Buying OpenBOM was much more of a business decision than a technology decision,” he says, OpenBOM has easily scaled to meet our needs over the past few years.

Simon explains how each of their products is actually a “Project”, custom in some ways and different from the last.

“Each client has its own set of needs, ranging from screen sizes (many over 4 meters), to cabling and other automation,” he says. “We spec and build all the components, including Printed Circuit Boards, and master them all in our OpenBOM, as a unique project with its own specific project (part) number.”

A typical project BOM for Design Technologies includes a very large screen, all the mounting system extrusions as a cutlist direct from Onshape, and the requisite electrical and electronics.

“We drive each project through a set of variables in Onshape, each having its own set of values and generating a specific project BOM in OpenBOM. That includes the specific cutlist for the shop floor and PCB board specs which we coordinate with our fab house to produce. All in OpenBOM.”

Even though each order is custom, there is a high degree of reuse in each project.

Design Technologies masters every part in an OpenBOM catalog, driven and maintained from Onshape and relying on unique properties and Category settings for each.

The ability to set a Category in Onshape and have it dictate exactly which Catalog the item is set to in OpenBOM is huge!” says Simon. “It’s all about reuse.”

Design Technologies also assigns a Vendor to each item in every OpenBOM catalog, which flows easily through the purchasing process.

Over time, and as the company matures, they are thinking about their designs as more of a database of items that they can rely on to fulfill the specific goals of a specific customer in a specific requirement.

“We have spent the past few years building a set of components which meet our customer’s needs and are reusable. OpenBOM coupled with Onshape helps us leverage all those common parts, even if it’s a standard extrusion, but in a specific length.”

Simon goes on to say that while OpenBOM fulfills a very functional role in the company, it is the unseen benefits that are often overlooked.

“Initially, we were thinking about a BOM as an output from Onshape. Now we see it much more as a product configuration, blending design from Onshape with customer and business requirements, and the project flows through to shipment.”

If you are wondering, those key decisions made in the pub that evening continue to pay dividends he says.

“I love that my team has access to all our data from anywhere, at any time. No more keeping a backup or duplicate entry, no wondering if we are managing all our data properly, I don’t care how it happens. That is a huge value to the company.”

“What I like most about OpenBOM is the seamless UX. OpenBOM works for us! Period.”

To learn more about Design Technologies LTD. please visit displaytechnologies.co.uk

To learn more about OpenBOM please visit www.openbom.com

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.