Founded in 2020 by Karl Neu, Thunder Basin Engineering offers its clients a wide range of engineering and design services, from prototype one-off performance items to highly configured, high-volume manufacturing equipment.

As Thunder Basin’s client list grew, Karl had to grow his company’s capabilities along with them.

He decided to bring in OpenBOM to make sense of all this data.

“I was absolutely tired of using Excel to manage bills of material”, says Karl, “by any measure, Excel was just not up to the task of managing my customer’s increasingly complex data”.

Karl’s deliverables often include a fully detailed CAD package (3D and drawings) and a complete costed Bill of Materials, in many cases for multiple configurations and variants.

“When looking for a BOM tool I had to consider I may have over a hundred configurations”, he says. “Excel was never going to provide the level of reliability that OpenBOM does”.

“In addition, the Solidworks integration was a major factor when selecting OpenBOM, it gives me a complete product structure Engineering BOM of the required configuration at the press of a button”.

Thunder Basin may use OpenBOM configurations to drive specialized manufacturing processes like 3D printing and plasma cutters.

“I like how the active configuration is recognized and the BOM and catalog item master information is always up to date. The OpenBOM settings dialog gives me complete control over which properties come from Solidworks to my BOM”.

Thunder Basin clients may also request very detailed supply line management information which Karl provides using OpenBOM; often identifying primary and secondary vendors, pricing, supplier part numbers, and more.

“We have recently included PCB design as part of our deliverable, and the recent announcement of the OpenBOM Octopart catalog integration is a big deal for us”, says Karl.

“Octopart is a key supplier to many of my clients”.

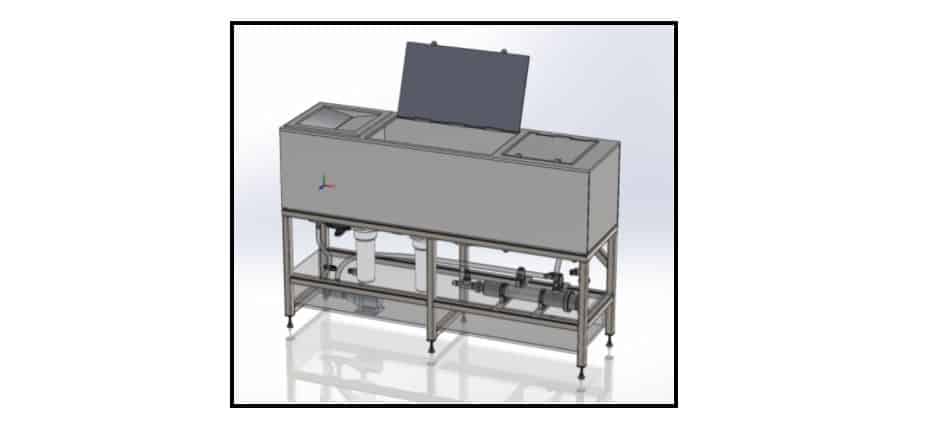

In fact, one of Thunder Basin’s clients, Logical Machines, a producer of manufacturing and weigh-fill machines, recently purchased their own license of OpenBOM to further improve their collaboration with Karl, and to improve their internal use of the data Karl provides.

“The ability to simply share the BOM with my client is a huge benefit to us both”, says Karl. “it greatly increases the value to my clients when I hand-off live BOM data that will serve them going forward”

Karl and Logical Machines collaborate on a common item master catalog so both parties can make updates in real-time as key decisions are made.

“Looking back over 10 years of spreadsheets the headaches are unbelievable, I’m an engineer, not an Excel programmer. Pivot tables and Vlookups are way too fragile to be reliable for manufacturing.”

Karl likes to tell a story of how OpenBOM helped him out of a pinch.

When a client lost a final production BOM for a machine they were currently producing, Karl used the OpenBOM multi-level spreadsheet import feature to recreate the BOM from some old Excels, with levels and all, bringing together the various Excels to create a single unified multi-level BOM in OpenBOM.

“The OpenBOM help page on importing multi-level BOMs from Excel was all I needed to get the job done,” he says.

In the end, Thunder Basin and Logical Machines enjoy the collaboration and reliability OpenBOM provides them both – as consultant and client.

At OpenBOM, we appreciate them both as customers.

To learn more about Thunder Basin Engineering please visit:

To learn more about Logical Machines please visit

To learn more about OpenBOM and try out your free 14-Day trial please visit www.openbom.com

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.