Gerry Gehrmann is a craftsman who describes himself as “a 35-year-old software developer who loves woodworking.”

In 2020 he turned to woodworking and embarked on a few projects that would become a beautiful piece of furniture, and he did it with Autodesk Fusion 360 and a non-commercial license of OpenBOM!

“I started woodworking in mid-2020, the first project was a mirror frame, then the jewelry box as a Christmas gift,” says Gerry.

“During the box build, I decided to go for hand tools only and to use traditional woodworking techniques.”

The completed hinged jewelry box (pictured) is made of walnut and hard maple.

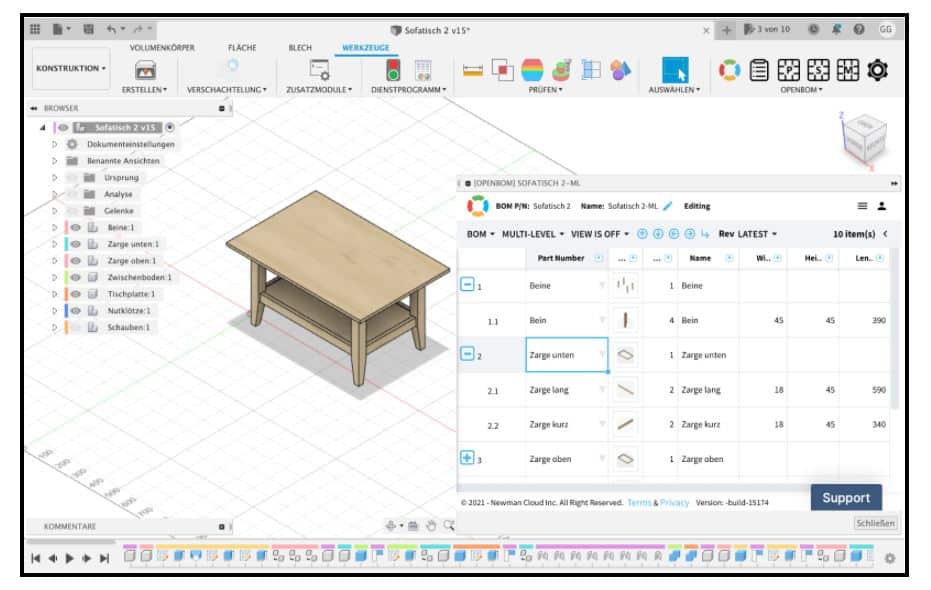

Later Gerry decided that the Shaker furniture style suits his design ideas best. So his current project is a Shaker-inspired coffee table made of elm.

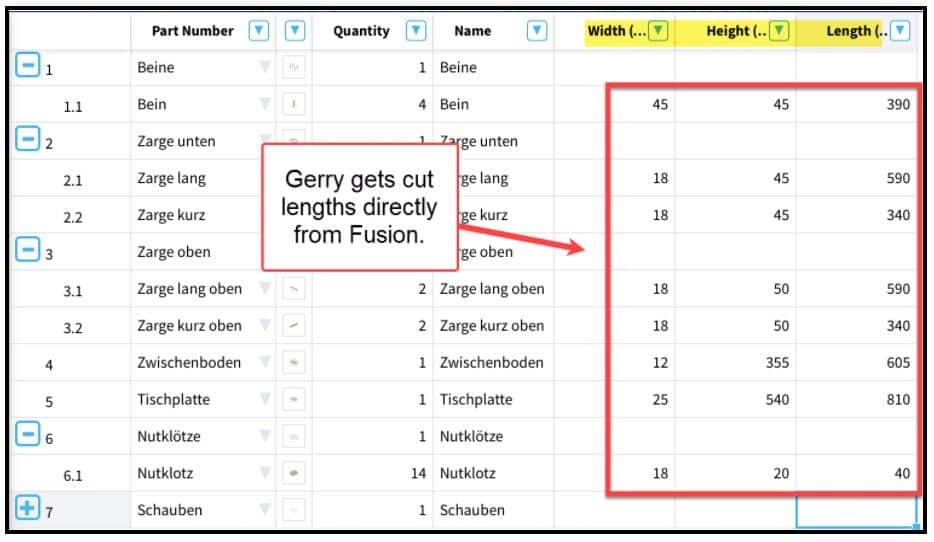

The coffee table is the first project that Gerry planned completely with Autodesk Fusion 360 and which the parts and cut-list were generated entirely by OpenBOM.

“OpenBOM brings an easy way to Fusion to create BOMs, even for complex multi-level component models,” says Gerry.

Gerry likes how OpenBOM helps him reduce material loss.

“Without OpenBOM I would have to measure every single part manually which is quite error-prone (e.g. forgetting to include tenons while measuring).”

We are excited to help Gerry bring his designs to life and look forward to his next project, two Shaker-inspired sideboards, and a desk.

We can’t wait to see them.

To learn more about OpenBOM please visit www.openbom.com

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.