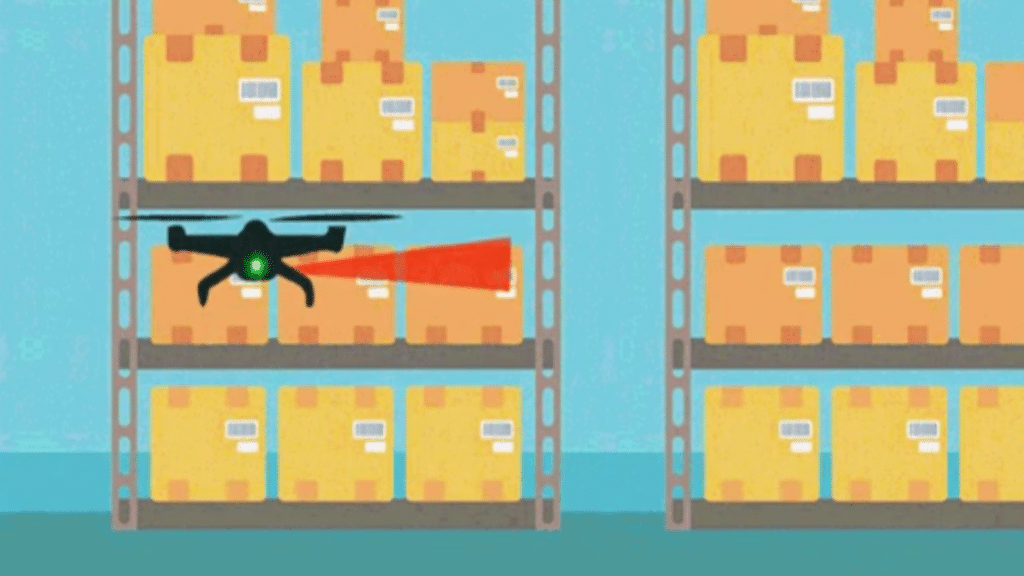

California Bay Area’s Corvus Robotics is a YC-backed startup redefining the way large-scale inventory is managed. The fully autonomous AI-driven Corvus One requires no fiducial markers to operate and uses a multi-camera vision system to fly completely unmanned inside warehouses. The drones collect data by performing cycle counts and help their clients across the country to improve inventory accuracy and optimize warehouse occupancy.

The product is a multi-discipline wonder, and they build it entirely on OpenBOM!

Founded in 2017, the company’s first products were designed and built in the MIT dorm room of CTO, Mohammad Kabir (who goes by Kabir). Kabir is also one of the founding members of MIT Driverless, as well as an early core contributor to the PX4 autopilot stack, which serves as one of the most commonly used drone autopilot systems in the industry.

As demand for Corvus One grew, the team went looking for technologies to help them quickly scale production.

“When we discovered OpenBOM, it fits perfectly into our fast-moving and agile development style here at Corvus”, Kabir says. “The decision to adopt it was a no-brainer, and now OpenBOM has become indispensable to our production team.”

“We are very happy users of OpenBOM,” says Jackie Wu, the company’s CEO.

Jackie explains how OpenBOM helps them reduce assembly errors and improve system reliability.

“OpenBOM has helped make our production process 10x more efficient, not to mention the qualitative improvements it makes in our hardware”, he says.

Corvus found that OpenBOM not only improved their quality on the front end of manufacturing but also in post-sale.

“Any fast-moving robotics startup will tell you that maintaining a reliable history of what we shipped is extremely difficult. With OpenBOM, we can go back and answer that difficult question, what was on the Serial Number we shipped to the customer?”

Mary Ma is the company’s Manufacturing Manager and is in charge of production planning and ensuring the consistency of the shipped product, including the post-sales support for kits and spares.

“Interestingly”, she says, “as much as our customers rely on Corvus One to find and manage their inventory, we rely on OpenBOM to manage ours!”

Mary goes on to explain, “we bought OpenBOM to solve a number of specific problems. First, OpenBOM tells us exactly how many and in which sub-systems each part is used, and helps make sourcing easier to manage. It also serves as a Manufacturing BOM on the assembly floor, calling out each sub-system as a flat bill of materials, allowing technicians to know exactly which items go next. OpenBOM helps with tracking hardware for new product development too. The Get Part Number feature in the OpenBOM Onshape integration lets our engineers assign part numbers to new designs that are in the works.”

Corvus also manages all sub-assemblies in OpenBOM, again, with the same commodity-based sequential part numbering method they use for individual parts. Item-specific information is added using OpenBOM’s property options to assign and manage meta-data.

“And the catalog thumbnails are awesome”, Mary adds.

As to moving BOMs onto the assembly floor, Mary explains more about how Corvus manages the production planning process.

“From the multi-level product BOM, we create an Order in OpenBOM for our next batch of units. The Quantity Gap (the on-hand inventory) is calculated and the buyers know immediately what we need to buy to complete that order. OpenBOM vendor sources have been pre-defined for each item to smooth the way when supplier shortages are encountered.”

CEO Jackie Wu wraps it up as follows, “With OpenBOM, our customers get products quicker, they fly more and have less downtime, it’s a win-win for everyone.”

To learn more about Corvus Robotics please visit https://www.corvus-robotics.com/

To learn more about OpenBOM please visit www.openbom.com

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.