OpenBOM has integrations with all CAD systems – MCAD, ECAD, PCB design tools. OpenBOM can be integrated with desktop, cloud and hybrid design tools. Some of these integrations are out of the box and some custom. I will tell you how OpenBOM CAD Add-ins can work. But before I will do so, let’s be honest and say one thing to ourselves.

You tried Excel or Google Spreadsheet for BOMs and it didn’t work…

A good chance you engineer in a manufacturing company that is working on design, engineering and production tasks individually or as part of the team. While you’re enjoying building innovative products and finding unique engineering solution, you’re struggling with the need to manage Excel files with a bill of materials, accounting for parts, quantities, rollup cost, mass, and many other management tasks, You continuously failing to communicate efficiently with other team members and the department responsible for production and purchasing. You’re stressed by the need to manually export data from CAD system counting parts, making updates.

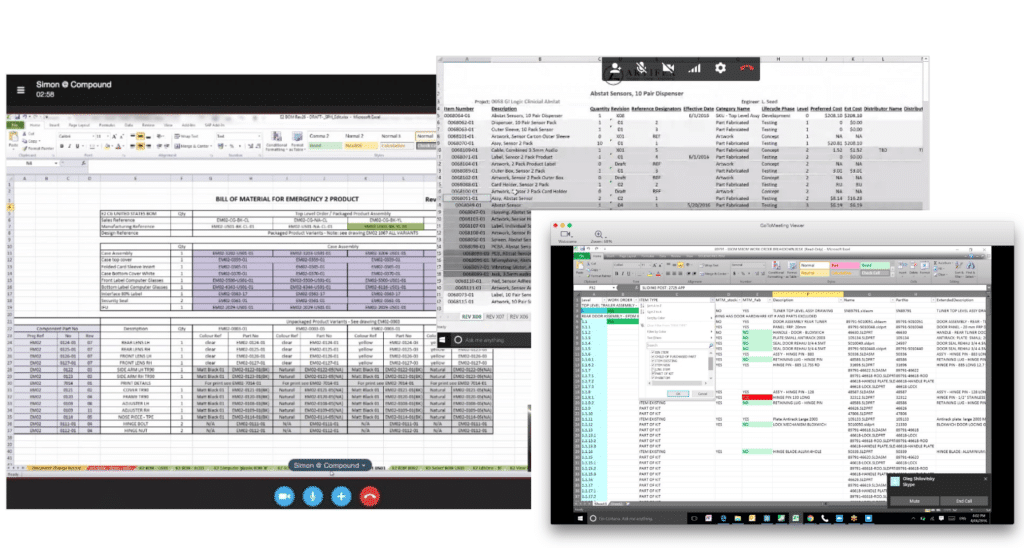

I grabbed a few examples of spreadsheets shared by our customers. Does it look familiar to you?

You have tried different Excel and spreadsheet templates. You tried a Google spreadsheet. They are simple to start with, but they are getting complex within time. Also, spreadsheets are absolutely not fit if you need to manage nested structures, rollup quantities, and having single data storage for parts – data is easy becoming redundant and everything is messed up. Also, sharing data with somebody else and updating it at the same time, is insanely complex. Data is often lost or not updated data is shared with the people that need to make purchases.

Staying with old fashion Excel spreadsheet, you can expose yourself to potential mistakes, production delays, excessive cost, and missing production targets. Somebody else will come to your place and will eat your lunch by developing products faster and at a lower cost.

By deferring to existing non-SaaS PDM and database solutions, you put your manufacturing and business goals at risk, exposing to significant IT and operational costs. By continuing to manage data using Excel and the variation of spreadsheets, you’re exposed to painful mistakes such as wrong orders and delays.

But you can escape Excel…

Here is the truth: You can easily escape messy Excels and stop doing manual Bill of Materials calculations. However, here is the thing – most software products out there are not equipped with a unique set of functions and capabilities as OpenBOM.

OpenBOM gives you a unique way to change what you do with the Bill of Materials and other related tasks in less than fifteen minutes. It is because of the unique technologies and CAD integrations we developed at OpenBOM.

Read what our customers saying about OpenBOM and CAD

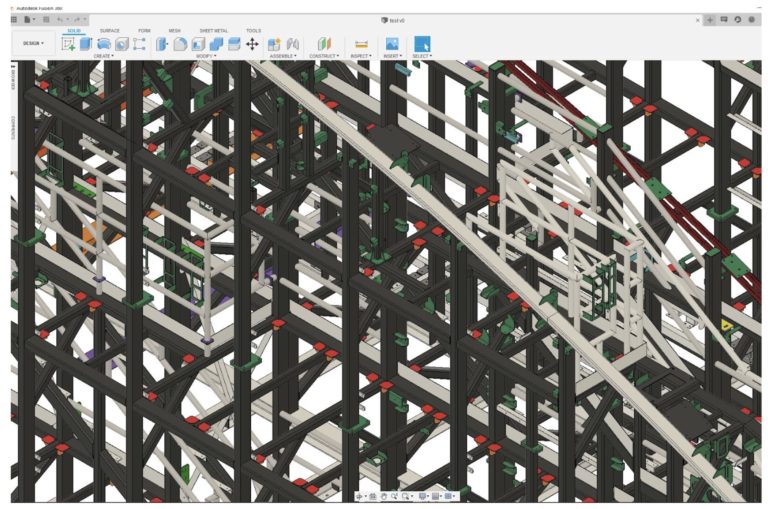

EA Manufacturing relies on OpenBOM and Autodesk Fusion 360 to solve a major manufacturing issue for a leading provider of massive outdoor structures. Brian Kraut and EA Manufacturing of Florida, USA, rely on OpenBOM and Autodesk Fusion 360 to solve a major manufacturing issue for a leading provider of massive outdoor structures. OpenBOM and Autodesk Fusion 360 collaborate to solve leading outdoor structure designers’ major problems.

Brian was contacted by a new client in big trouble. They had a very large investment of time and money into a design (by another design firm) which was ready to go to manufacturing. But the client could not go to the manufacturing phase because they didn’t know how many of each component they needed. The client asked the original designer to provide the detailed Bill of Materials but they could not. Keep in mind this is a complex design, with mirrored parts, left and right parts, assembly variants, configured lengths, etc.

“My client was stuck and needed someone to take their design data and turn it into a manufacturing Bill of Materials”, says Brian. This is where EA Manufacturing and OpenBOM stepped in.

The client sent Brian a STEP file over 1.2Gb! Brian uploaded the file(s) into Autodesk Fusion 360 and began to organize the design. He discovered the design had over 24K individual parts, which OpenBOM and Autodesk Fusion 360 handled nicely.

Brian used the OpenBOM for Autodesk Fusion 360 add-in to create a Multi-Level BOM of the entire design. However, it was OpenBOMs Flatten function which really provided the power Brian (and the client) needed. Brian used Flatten to identify ALL the individual parts and assemblies AND THEIR QUANTITIES (regardless of their location in the product structure) so they could take the design of the steel manufacturer and have the correct number of parts made!

“I love how the thumbnail images displayed on the screen and in the exports. The material types, thicknesses, and other part properties also came through into the BOM literally saving me hours of time specifying material properties for each part” says Brian. “Having Multi-Level product structure is great!” he added.

Long Beach, California based X-Naut making the entire X-naut team from design to supply line to manufacturing rely on OpenBOM and moving away from not organized data in Excels. X-Naut is using Solidworks and creates Catalogs, BOMs necessarily to make their products directly from Solidworks using OpenBOM add-in.

As demand for the unique products quickly grew X-naut found themselves hustling to managing the components and supply lines necessary to meet the expanding demand. X-naut relies on OpenBOM to quickly capture the product structure form the 3D CAD designs and create the Items, Catalogs and Bills of materials necessary to produce their products.

“The ease of use coupled with the production planning features of OpenBOM give us the ERP features we need without all the ramp time, cost and maintenance of an on-premise system,” says X-naut CEO Darren Saravis. “OpenBOM’s ability to quickly bring together design and vendor information into a purchase order and manage quantity on hand helps us manage demand and inventory at our off-shore facilities”.

Navigate to this link to learn how OpenBOM import data from any CAD SYSTEM