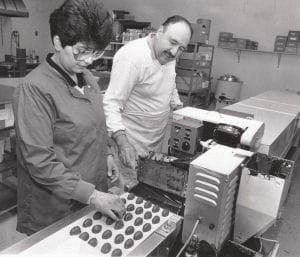

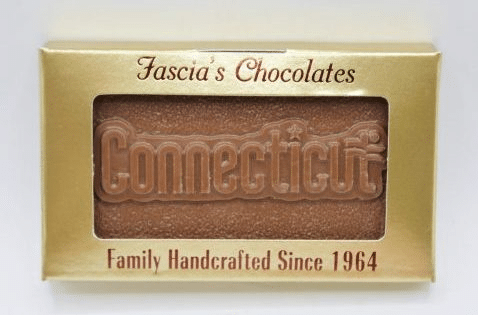

Fascia’s Chocolate of Waterbury Connecticut is a family-owned chocolatier started in 1964 by Mr. & Mrs. Fascia that still operates today in much the same way it did 58 years ago, only with a hint of the modern as they manage their production with OpenBOM.

Bill Thomas is the company’s Operations Manager and is charged with bringing the 21st-century techniques their customers demand to the very traditional operation.

“We did not have an adequate way to understand our costs”, says Bill. “We had some tabs in an Excel spreadsheet but it wasn’t working anymore, especially as customer demand grew”.

Even though the company still operates out of a storefront in Connecticut, recent years have seen the company business become so much more than retail. In fact, they have shipped more products in the last two years than any two years in history!

“We provide products for market chains, corporate business events, wholesale fulfillment, and of course, to our valued storefront customers”.

If you want anything covered in chocolate or a custom corporate logo on a chocolate bar, Fascia’s is the place to go!

Bill has modernized the business to rely on the ERP features of OpenBOM.

“We manage our ingredients and products with OpenBOM.”

According to Bill, “we create a catalog for ingredients, cooking and labor times, and more, then create a complete product BOM.”

“OpenBOM is so much simpler than Excel. As material costs have been changing so much lately, it’s comforting to know that when I change an ingredient cost in one place, it updates in all of our product recipes.”

“We love how OpenBOM rolls up the cost of all the ingredients to the top-level finished product.”

And it’s more than just cost that Fascia’s is keeping track of in OpenBOM.

“As our business has expanded to much more online orders, we use OpenBOM to not only keep track of costs but for weight!”

“The BOM is our recipe. We add labor, timing, overhead, shipping, everything that goes into the delivery of our products to our customers.”

With OpenBOM we understand the unit economics of our chocolates!

“Honestly, we really didn’t evaluate a lot of ERP systems. We liked the affordability of OpenBOM so we gave it a try. In the end, it has been a great choice for us”, says Bill.

A day in the life for Bill, “When I’m not shipping or receiving products, I am setting up our catalogs and making recipe BOMs.”

Fascia’s Chocolates has broken down its recipes into individual steps that can be defined in OpenBOM. Essentially a sub-assembly.

“Take caramel, for example, we use a lot of caramel. I have a recipe (eg. BOM) for caramel that is included in so many of our products. I created a SKU in OpenBOM, added it to a Catalog, as raw materials.”

“Now we can easily forecast caramel demand, something that was hard to do without OpenBOM.”

Bill has even broken out specific types of time, overall time vs. applied time (human time). Fascia’s relies on OpenBOM to assess the actual labor costs vs. cook time.

“Like so many companies, we have been faced with price increases, both on our raw materials and on the operations side as well. OpenBOM allows us to accurately understand those costs and properly adjust our pricing,”

OpenBOM has taken the guesswork out of the process.

To learn more about Fascia’s Chocolates or to place an order please visit

To learn more about OpenBOM please visit

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.